This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

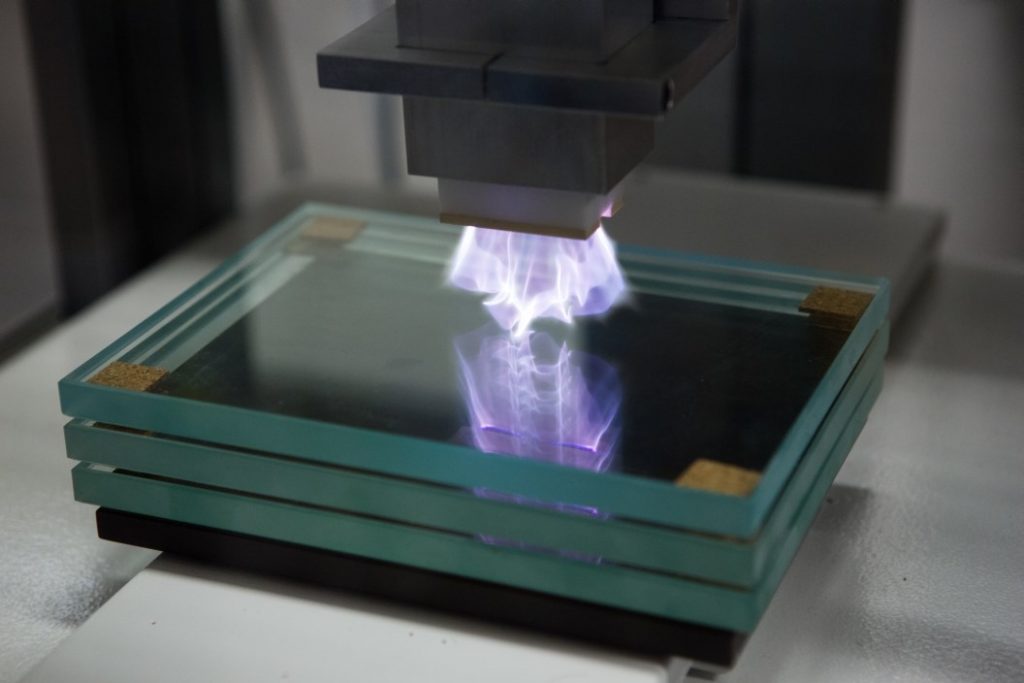

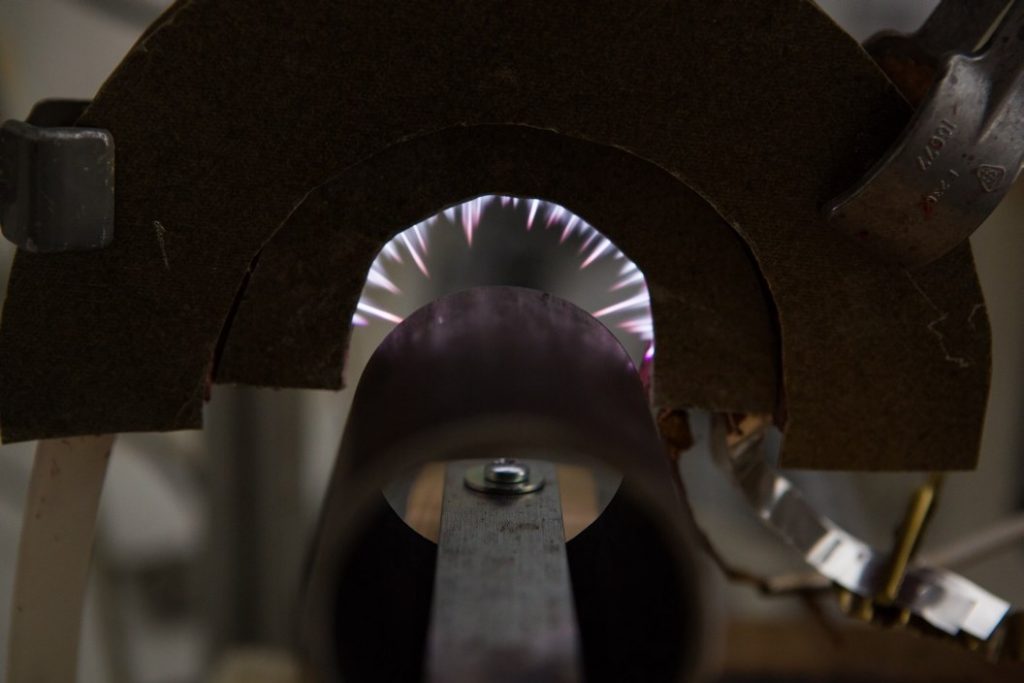

Plasma surface activation

The surface of the material plays a key role in a number of applications, and the modification of its surface conditions typically starts with an activation process. During this step, reactive groups are created at the surface of the material, with the groups typically serving as a “mounting” for any specific groups generated in the next step. The latest gaseous plasma-based technologies have a unique potential to activate a surface, meeting the requirements on speed, homogeneity, process stability, efficiency, and, primarily, achieving a zero environmental impact. Surface activation using plasma can activate approximately 10 nanometers of a surface layer, including a surface on very hard-to-reach areas, making it an unparalleled solution for a universal non-destructive surface treatment.

The latest research at CEPLANT concentrates on plasma surface treatment for industrial installations at atmospheric pressure. The goal of plasma surface treatment is improving the surface conditions of a material for further processing, nano-manufacturing, advanced coating, fusing or 3D printing.

These activities include research focused on modern plasma nanotechnologies such as plasma surface functionalisation, activation, cleaning, etching and calcination that can be used for advanced material processing, and are environment-friendly.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the