This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

Plasma technologies

Plasma technologies offer a wide range of applications from coating using a wide selection of materials to waste processing and medical use.

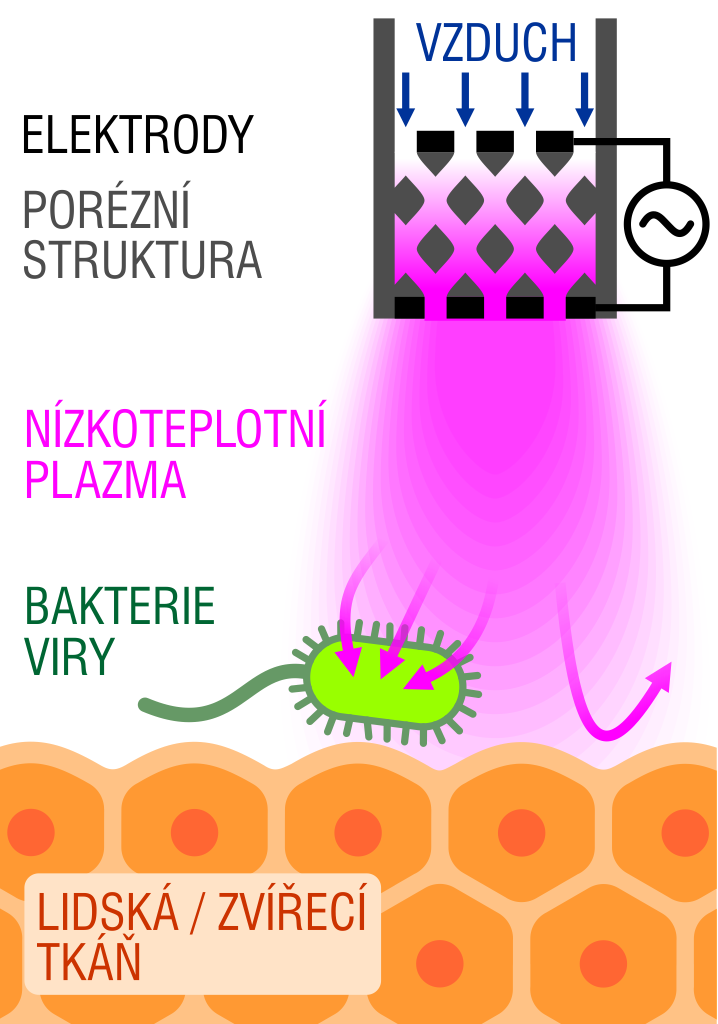

Plasma in medicine

Low-temperature plasma

Due to its ability to destroy bacteria, viruses and fungi, plasma can play an important role in helping save lives of humans and animals. For the entire process to work, a patented technology is used, which unlike the traditional examples of plasma (such as fire, Sun) creates a plasma of only 37 °C. Such a temperature is not harmful to either the human or animal tissue, but is destructive to foreign organisms. The technology has obtained certification for veterinary use, the certification process for medical use has been in progress. More >>

Available in the NCC for MATCA:

PlazmaFor-M

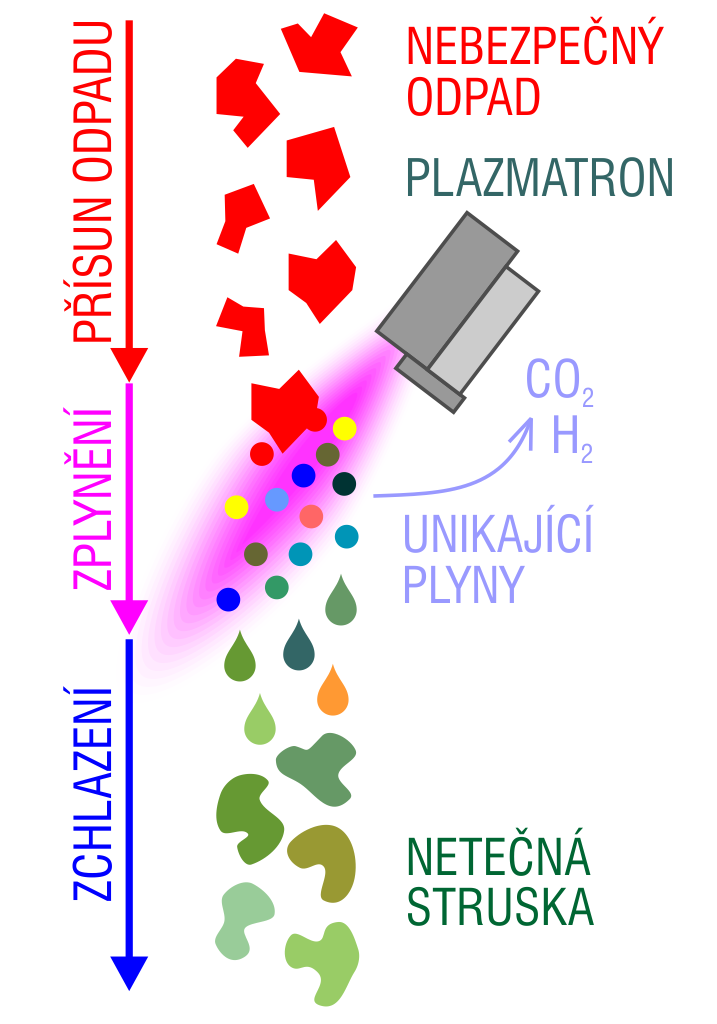

Plasma gasification

Plasma gasification

Plasma gasification of waste has a significant potential for processing specific waste types. The waste is exposed to identical temperatures as those at the Sun’s surface. This extreme thermal process decomposes the waste into individual atoms, converting it into a synthesis gas, and a small amount of solid stable material. The most important types of waste primarily include unused household residues, hazardous waste from hospitals and hazardous chemical waste, including paints, fertilizers, petroleum products, asbestos etc. More >>

Available in the NCC for MATCA:

PlasGas

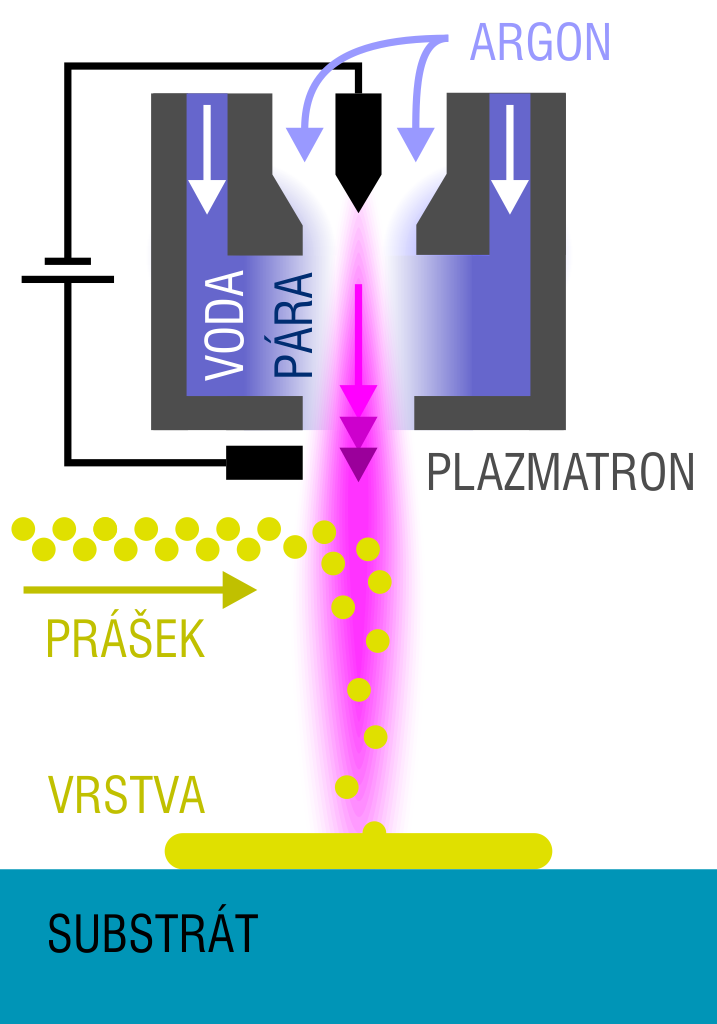

Plasma coating

Hybrid water-stabilized plasma spraying

Hybrid water stabilized plasma spraying (WSP-H) is a novel hybrid technology using a plasma torch that combines the benefits of a classic gas stabilized DC arc torch with a uniquely designed water duct. More >>

Available in the NCC for MATCA:

WSP-H 500

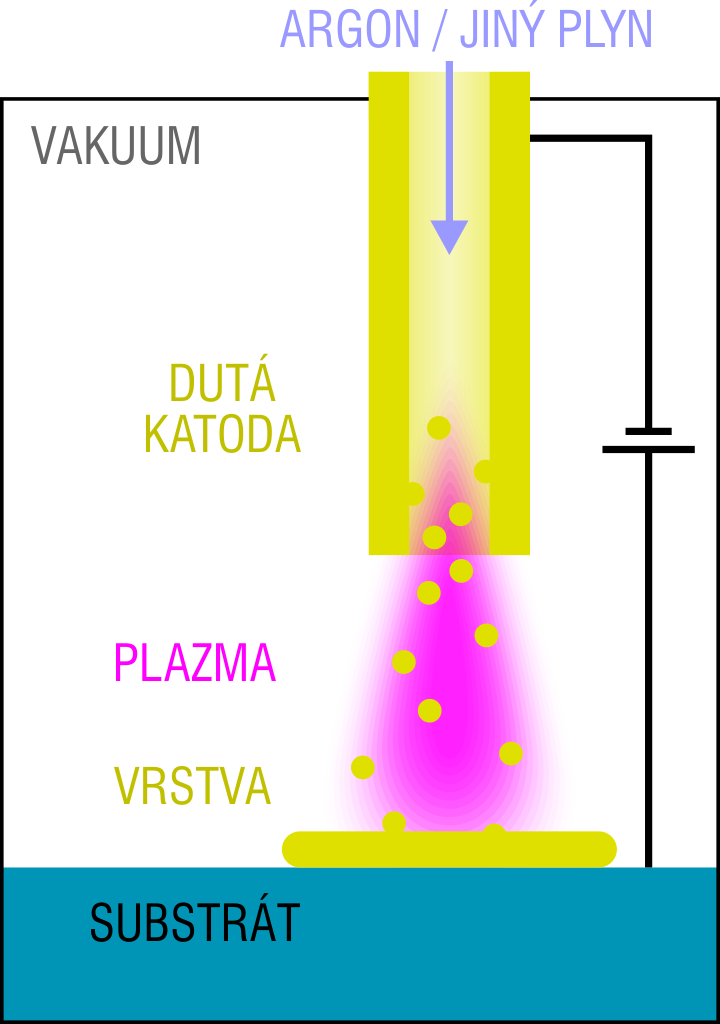

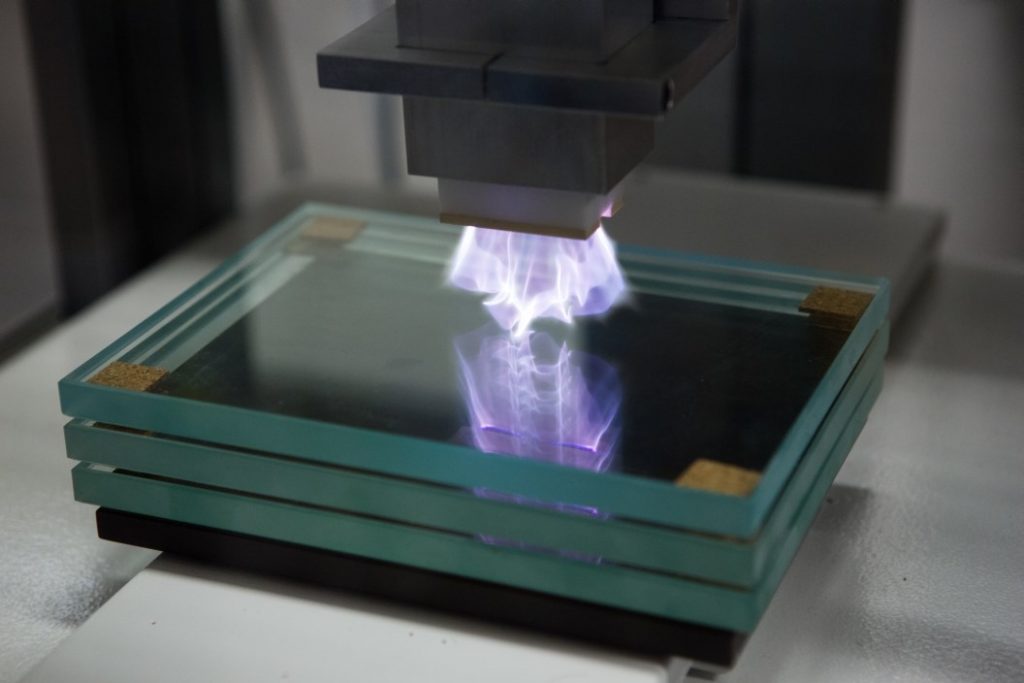

Hollow cathode

A hollow cathode deposition system is based on hollow cathode magnetron sputtering in the reactive atmosphere of the operation gas. The hollow cathode provides a high degree ionisation that causes not only an intensive cathode sputtering process but also the ionization of a reactive gas, and the subsequent improvement of the properties of the deposition layer induced by an increased bombardment of the substrate. More >>

Available in the NCC for MATCA:

more than 5 devices

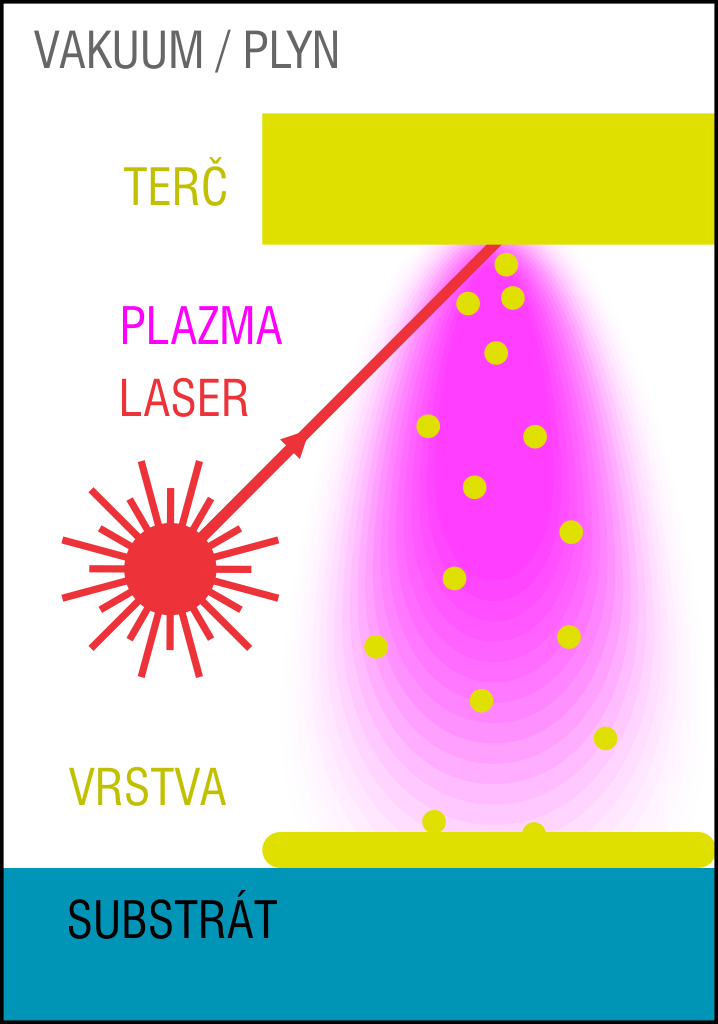

Pulse laser deposition

Pulse laser deposition (PLD) is a method for creating inorganic and – to a limited extent and subject to some modifications – organic thin layers from materials with a complex elemental composition. In its original form, this method was first published in 1965. More >>

Available in the NCC for MATCA:

more than 5 devices

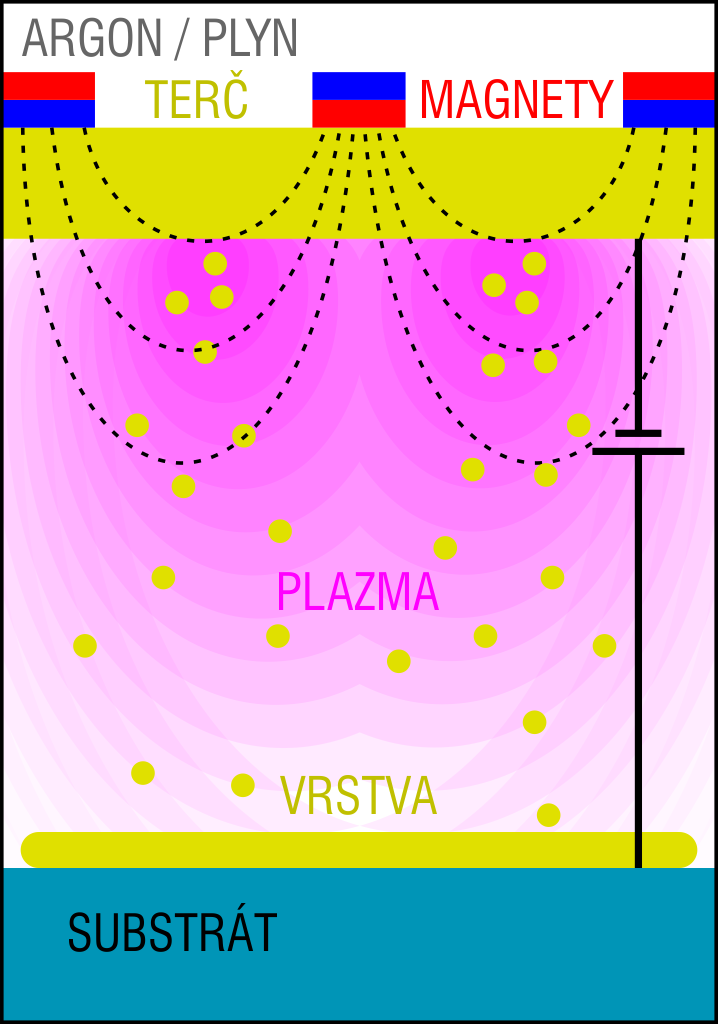

Magnetron sputtering

Magnetron sputtering (MS) is a deposition method that uses targets from a conductive material placed into a vacuum chamber and connected to a high negative voltage. An operation gas (typically an inert gas – such as argon) is fed to the chamber, with the pressure in the chamber maintained in the range of tens to units of pascals. More >>

Available in the NCC for MATCA:

more than 5 devices

Plasma surface treatment

Plasma surface activation

The surface of the material plays a key role in a number of applications, and the modification of its surface conditions typically starts with an activation process. During this step, reactive groups are created at the surface of the material, with the groups typically serving as a “mounting” for any specific groups generated in the next step. More >>

Available in the NCC for MATCA:

more than 5 devices

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the