This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

WHY

Material surface plays an important role in a number of technical applications. By modifying it, we can improve not only mechanical properties or anti-corrosion resistance, but also create special or even unique surface properties.

HOW

High-quality know-how and extensive experimental equipment enables us to develop surface treatment for specific applications

WHAT

At the NCC for MATCA, we deal with surface treatments from the design and implementation to testing and building surface coating apparatuses.

Custom surface coating

In cooperation with our partners within the NCC for MATCA, we focus on surface treatments for various applications across all industries. We place special emphasis on plasma and laser technologies, the development of which we actively participate in. According to specific requirements or applications, we design and create coatings of special or even completely unique properties, pre-treat surfaces or, by activating the surface, we create conditions for ensuring a final high-quality coating.

Developing coating apparatuses

More demanding requirements on surface treatment and the development of coatings of special properties goes hand in hand with the development of coating apparatuses. New coating methods very often require new constructions of coating apparatuses or completely new apparatuses. At the NCC for MATCA we cooperate with leading Czech experts and actively contribute to the development of new apparatuses, their testing and subsequent commissioning in the production environment.

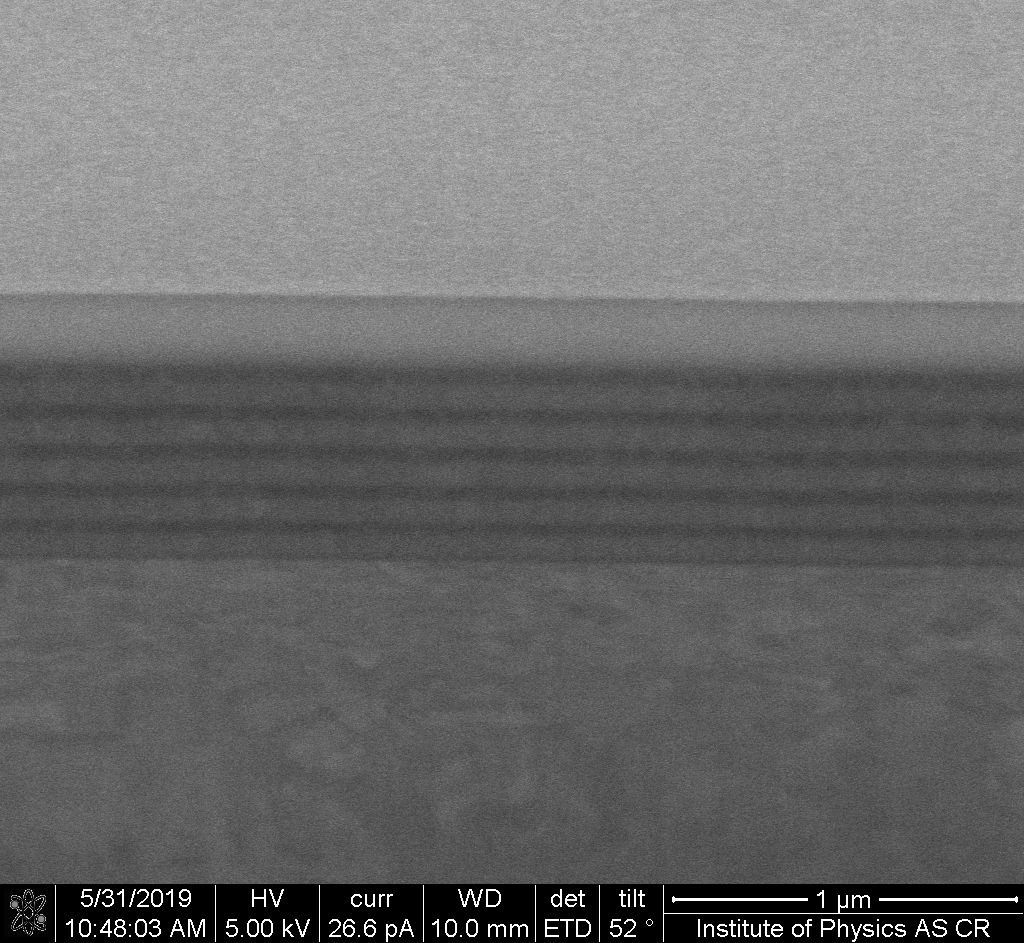

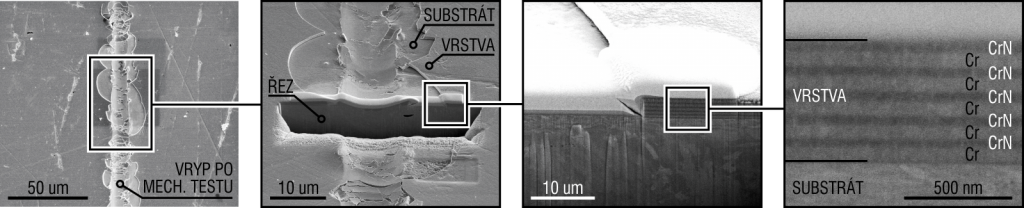

Layer characterisation

Characterisation and analysis of coating properties and surface treatment is enabled by extensive experimental equipment. Using suitably chosen analytical methods, we can determine a number of coating layer properties such as its hardness, tribological properties or thickness, whether the it is the overall thickness of a coating or of individual sub-layers in special coatings. Also, a suitably chosen method enables us to determine the chemical composition of a coating without influencing the measurement by the basic material.

Do you have any questions?

The range of analytical methods available in the NCC for MATCA is too extensive to be fully outlined here. If you have any questions concerning a specific application, don’t hesitate to contact us.

Related technologies

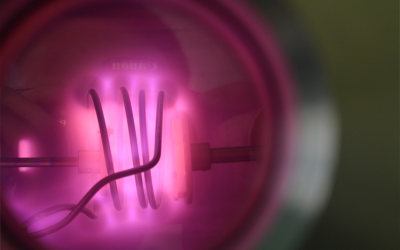

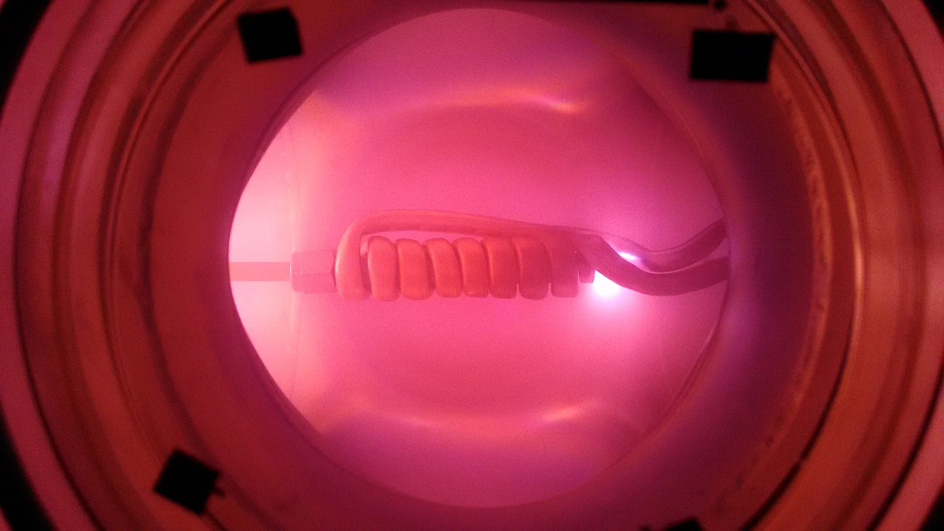

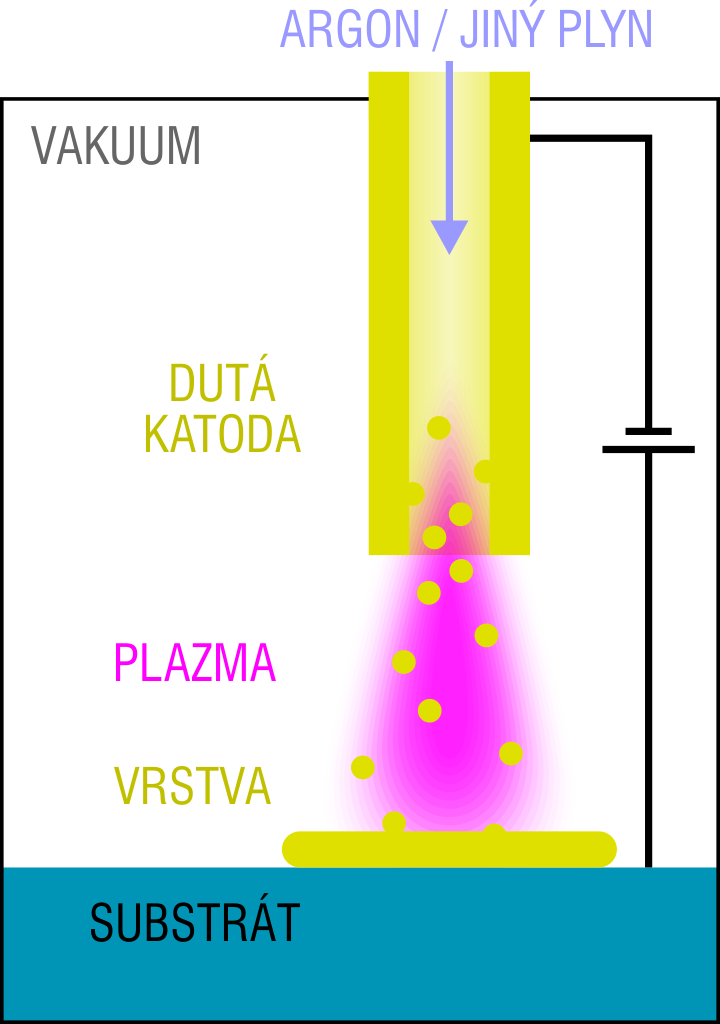

Hollow cathode

A hollow cathode deposition system is based on hollow cathode magnetron sputtering in the reactive atmosphere of the operation gas. The hollow cathode provides a high degree ionisation that causes not only an intensive cathode sputtering process but also the ionization of a reactive gas, and the subsequent improvement of the properties of the deposition layer induced by an increased bombardment of the substrate. More >>

Available in the NCC for MATCA:

more than 5 devices

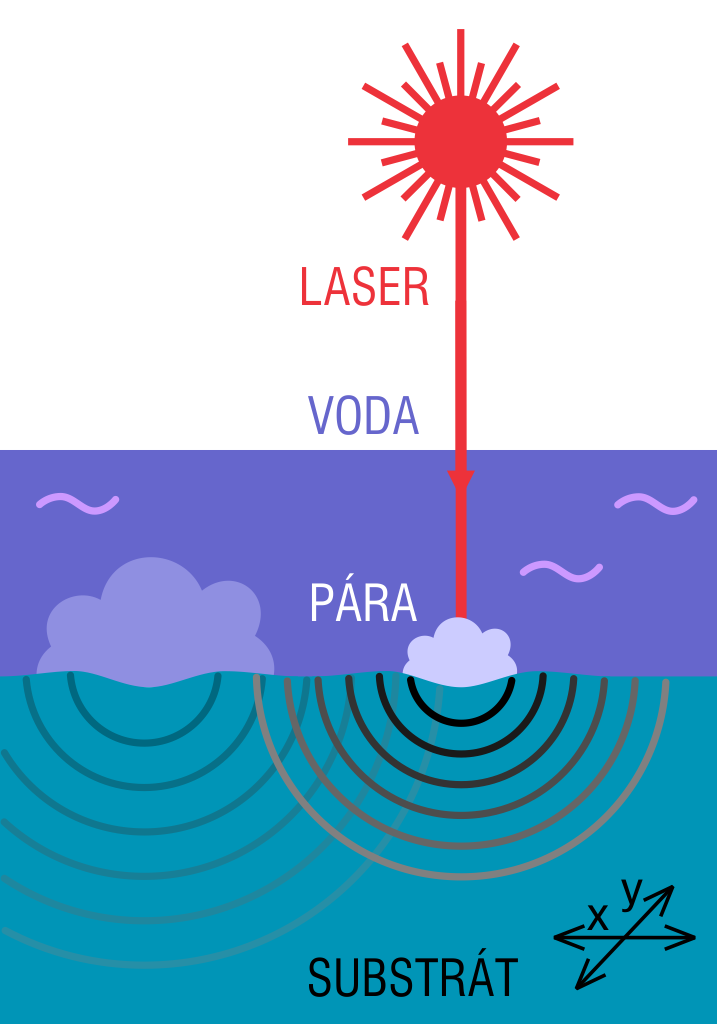

Laser Shock Peening

Laser Shock Peening (LSP) is a process that uses nanosecond high-energy laser pulses to create compressive residual stresses in the material, with nominal depths of up to 1.5 mm. More >>

This technology is available in the consortium.

Related services

Measurements and testing

The ability to analyse parts, samples or any input material is a key prerequisite not only for efficient research work, but also for a reliable production process and the identification of causes if any problems occur.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the