This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

Additive manufacturing

3D printing or additive manufacturing allow the fast manufacturing of complex shape plastic, metal parts or parts from other materials. This webpage outlines commercially available additive technologies and their availability within the NCC for MATCA.

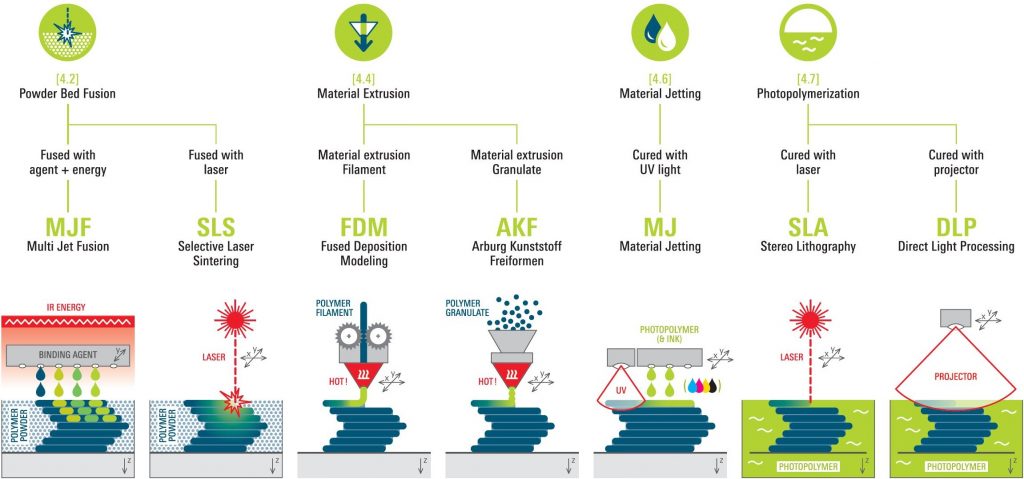

Plastic 3D printing

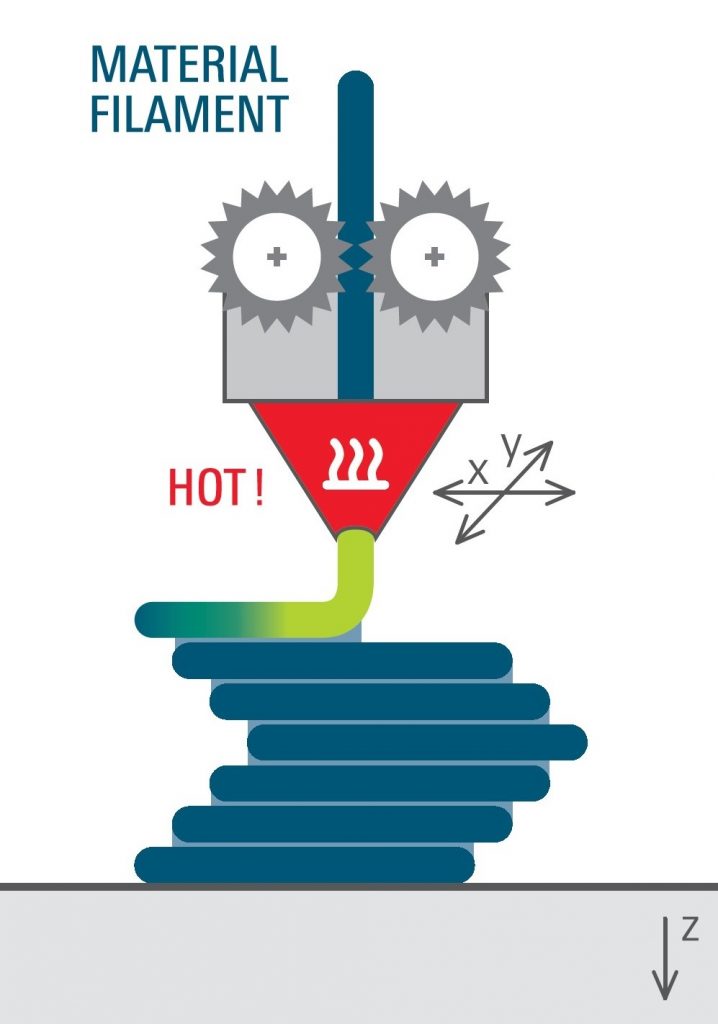

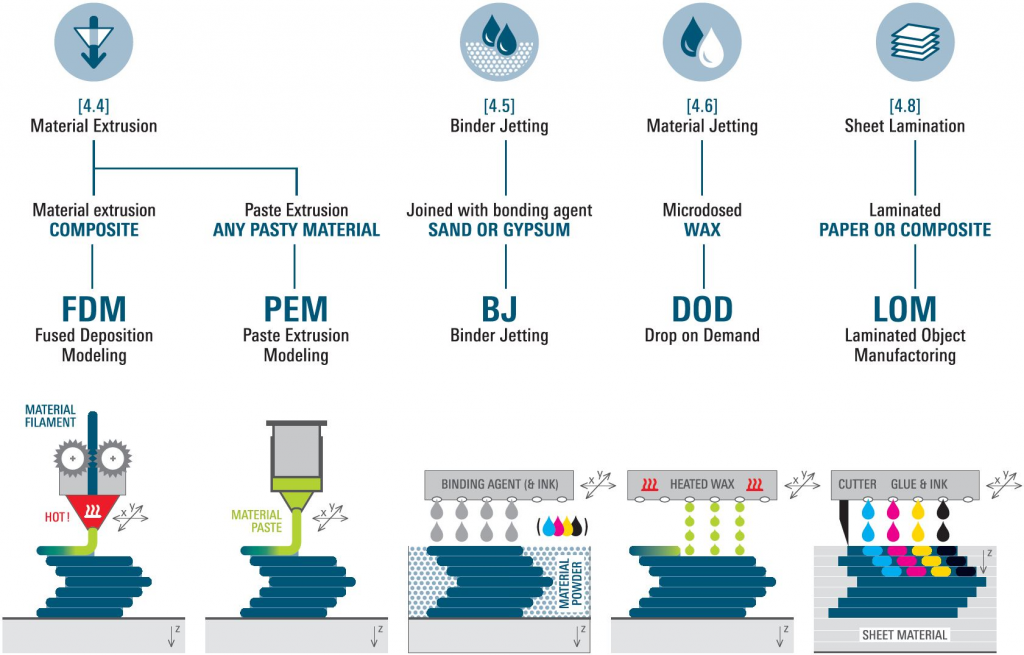

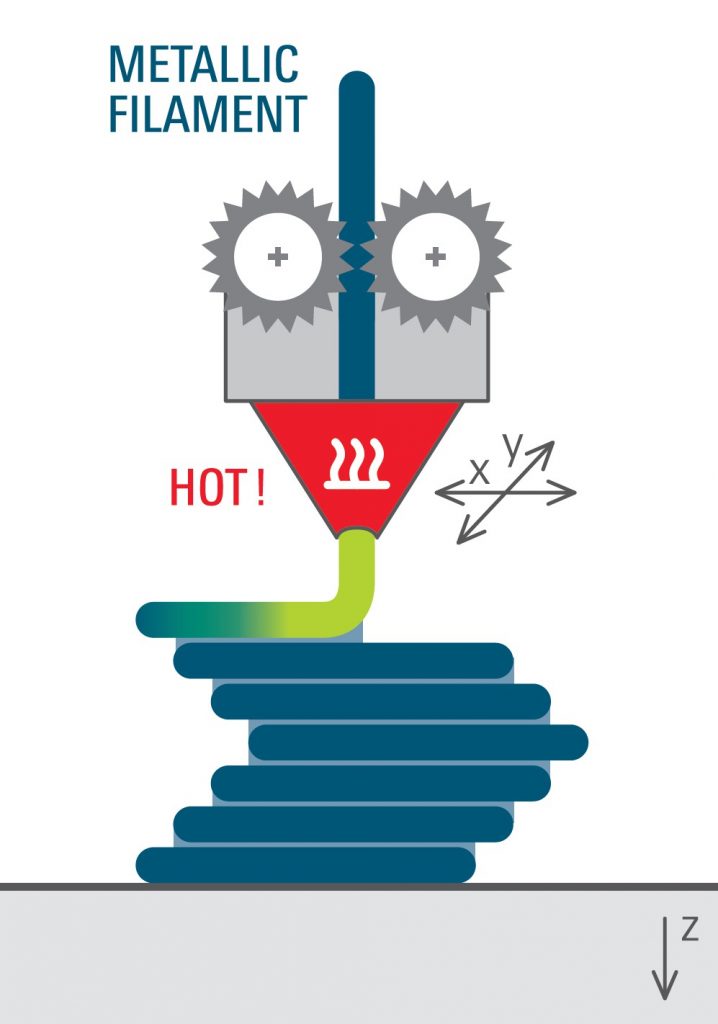

Fused Deposition Modelling (FDM)

The printing process is based on the deposition of individual layers of molten thermoplastic that are supplied to the print head in the form a filament or granulate. After its application, the molten material cools down and solidifies. The resulting quality of the product relies on printer design quality and on how well the printing parameters are tuned to the thermoplastic and the printing machine used. More >>

Machines in the consortium:

Stratasys Fortus 450mc

Prusa i3 MK3s

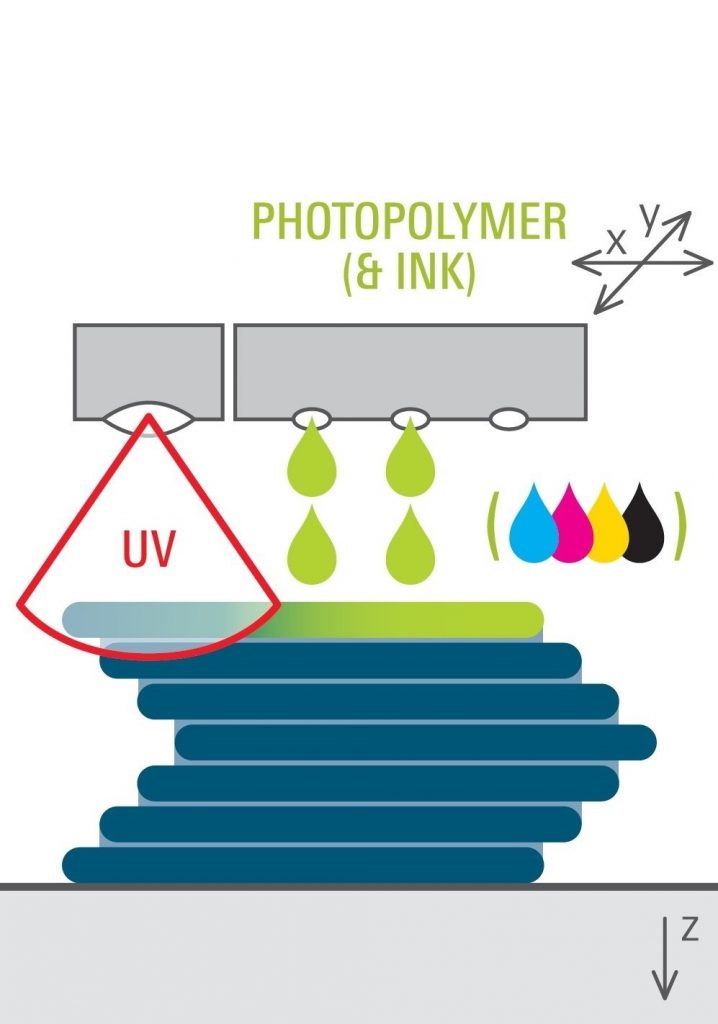

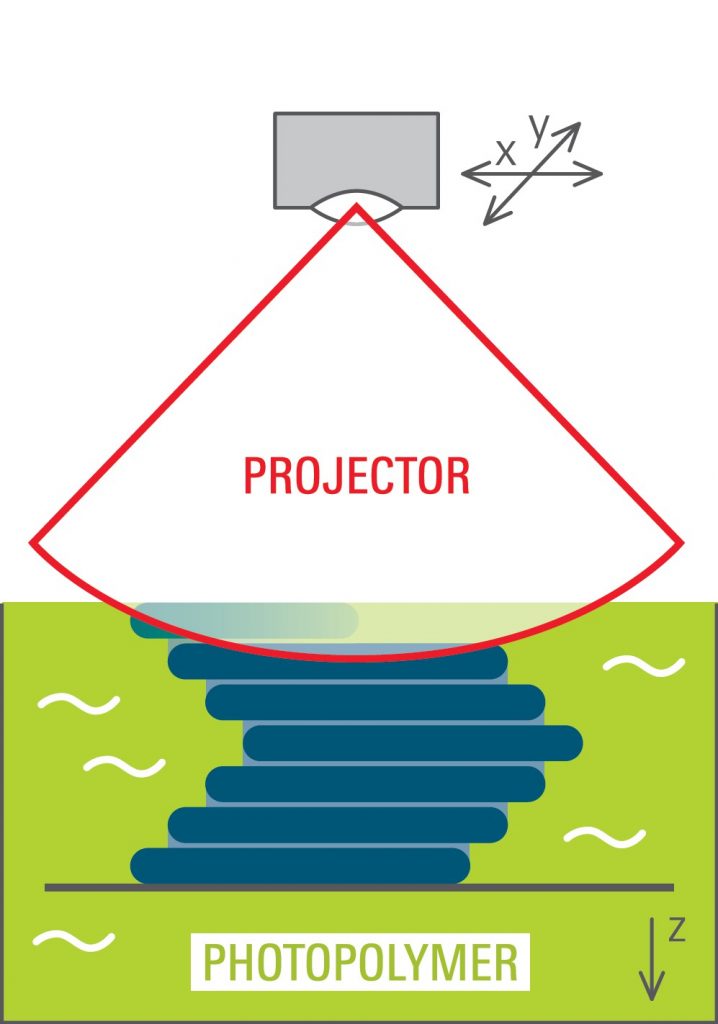

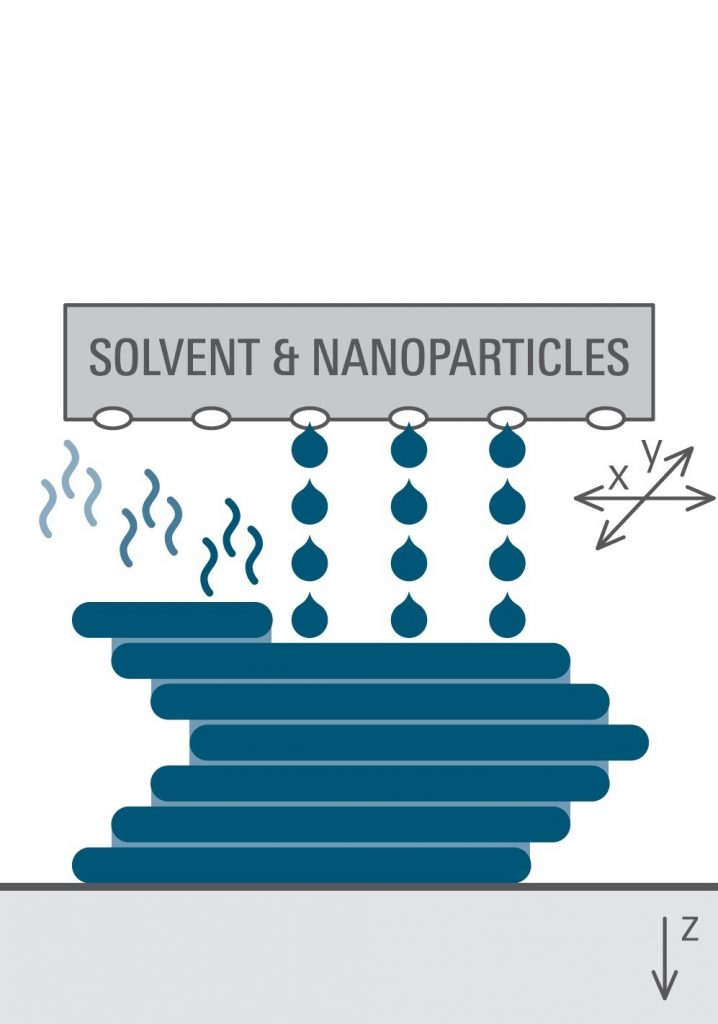

Material Jetting (MJ)

Material jetting is one of the fastest and most precise 3D printing technologies. The parts here are created by applying photopolymer drops, which are subsequently hardened using an UV radiation source. The printer can apply the material from several print heads simultaneously, enabling multi-colour or multi-material printing at the same time. The entire process is repeated layer-by-layer until the whole part is complete. More >>

Machines in the consortium:

Stratasys Objet 500 Connex1

Stratasys Objet J750

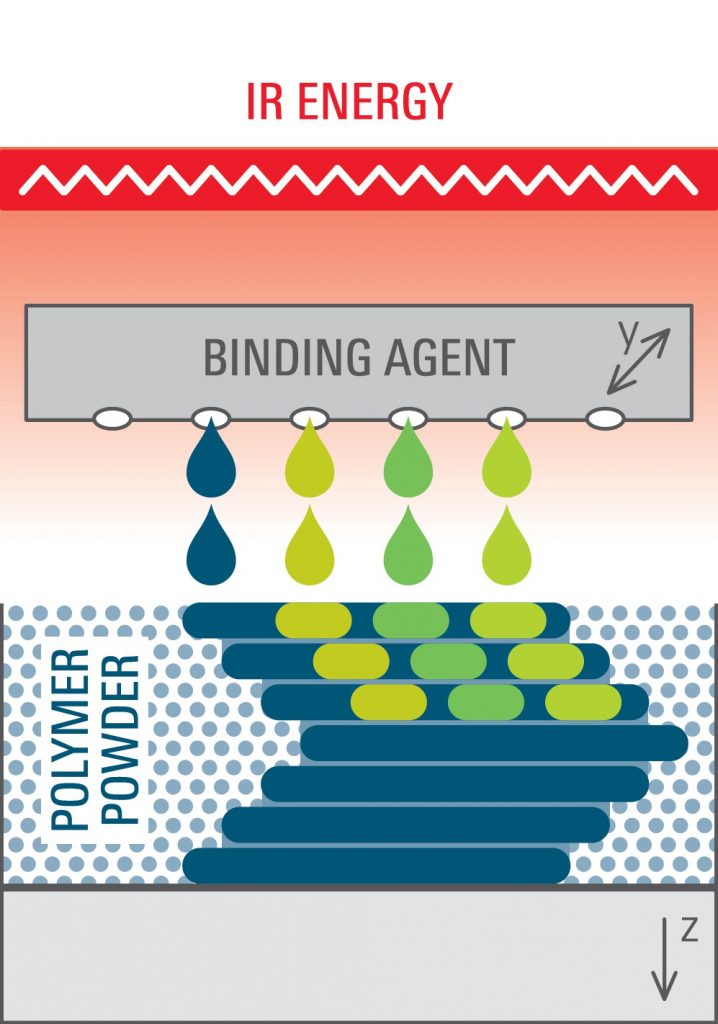

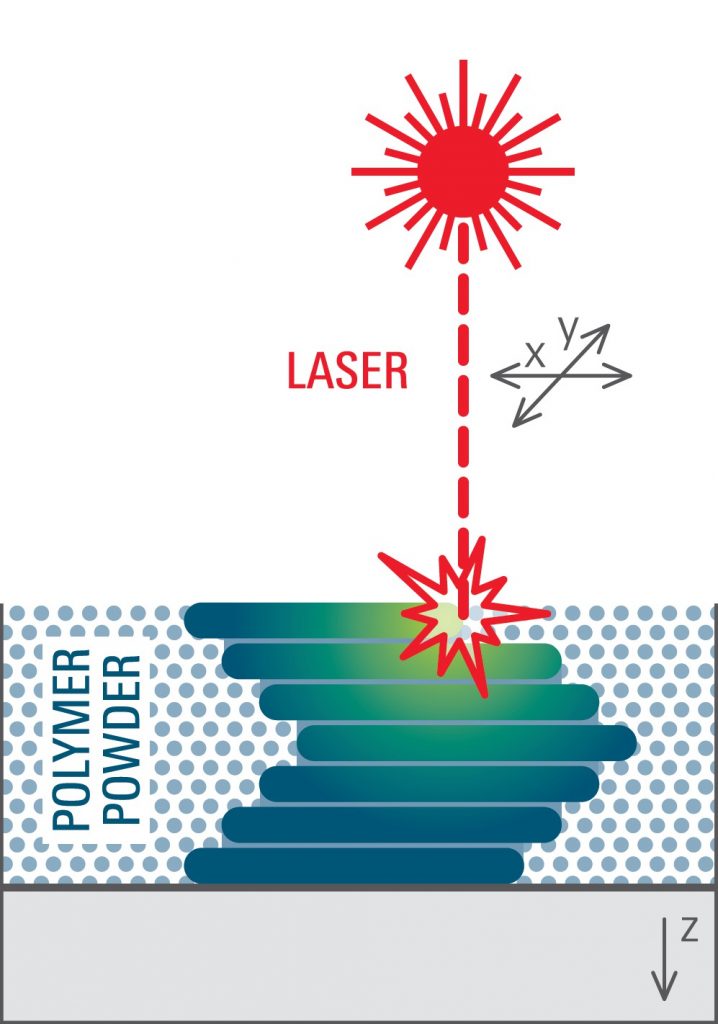

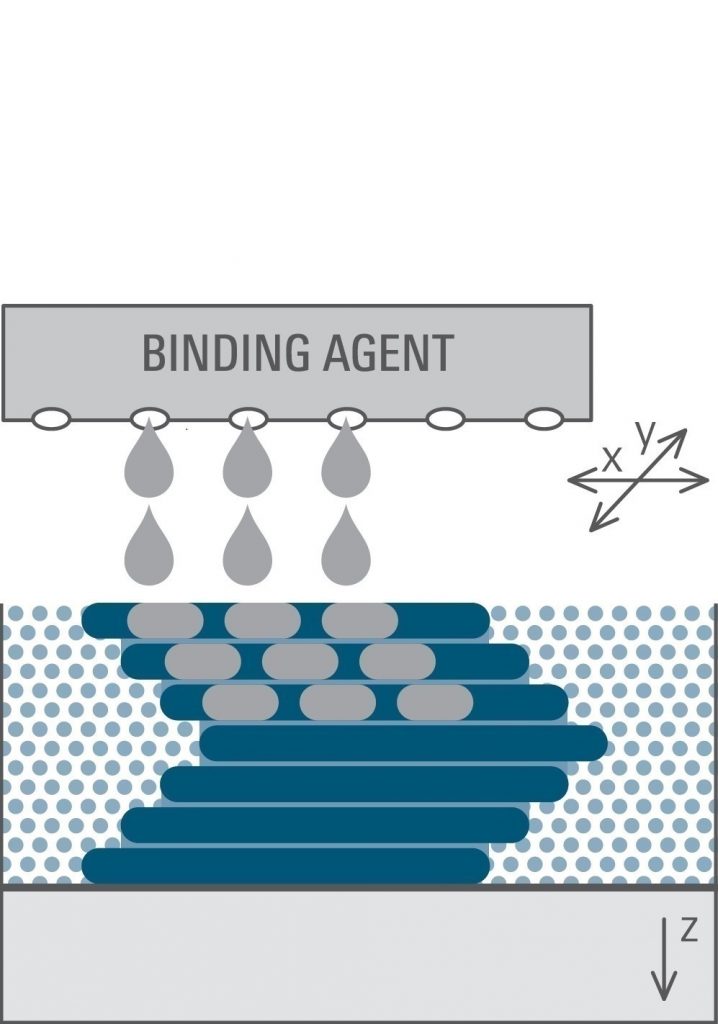

Multi Jet Fusion (MJF)

The printing process consists in the application of a glue (a binding agent) on the layer of plastic powder in areas defined by the shape of the manufactured part. The agent enhances the absorption of the IR radiation, causing the powder on the locations sinter. The benefit of the technology is the speed of production of highly rigid parts. They can be used as functional mechanical parts unlike the products of other 3D plastic printing technologies. More >>

Machines in the consortium:

HP Jet Fusion 3D 4200

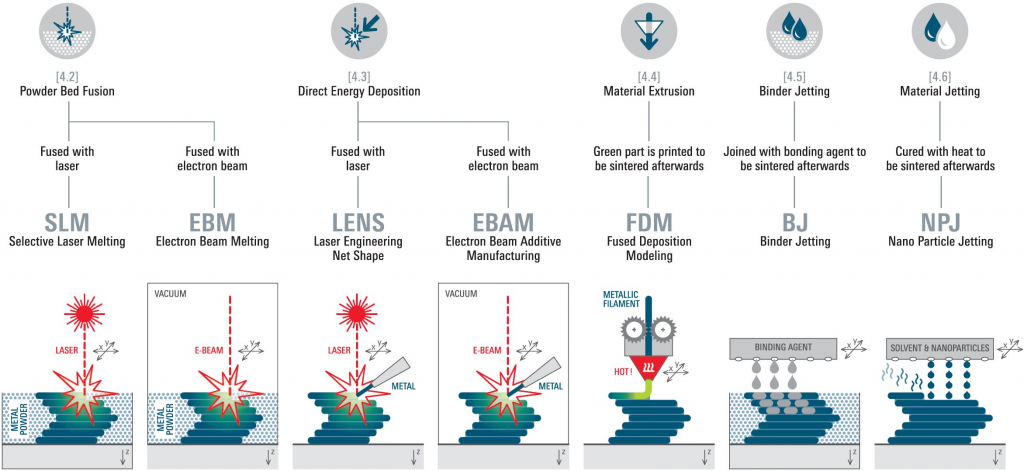

Metal 3D printing

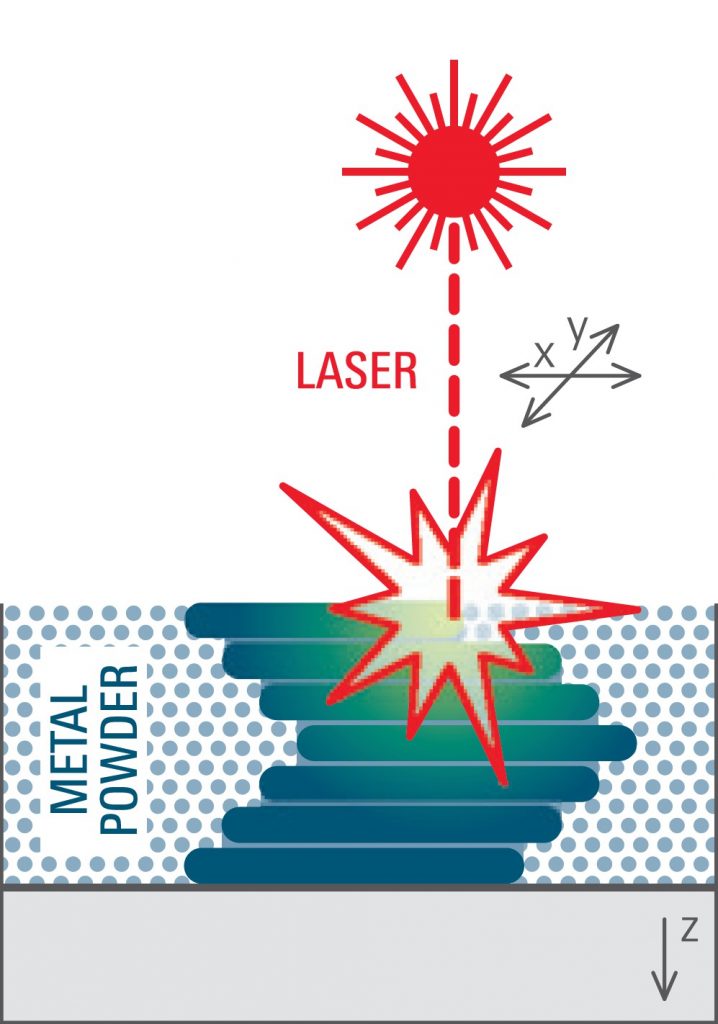

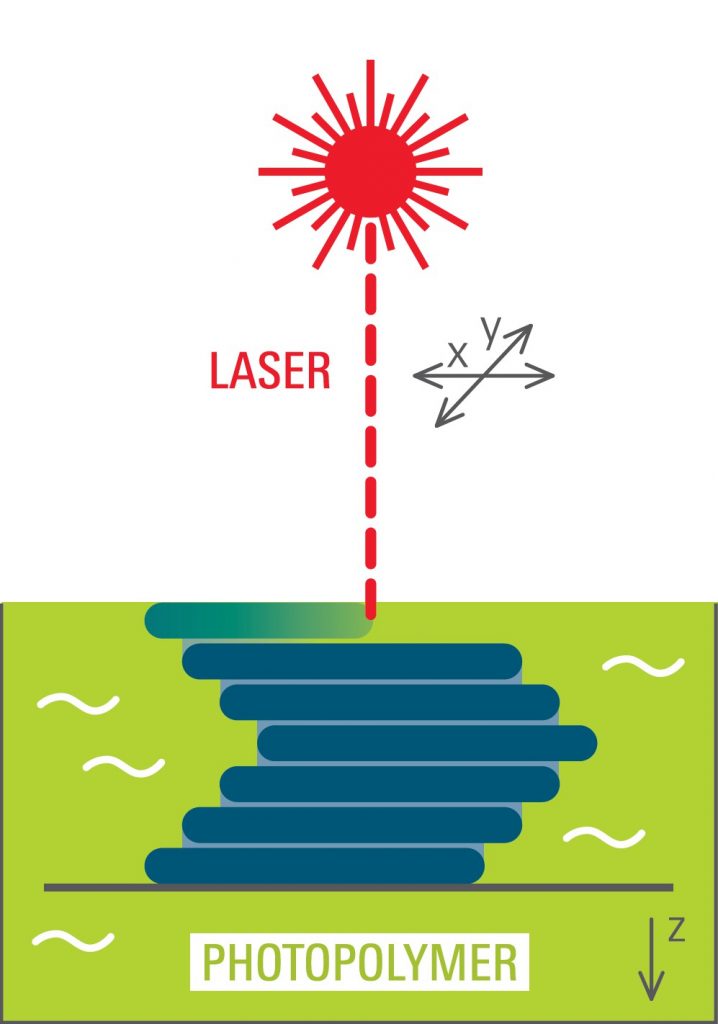

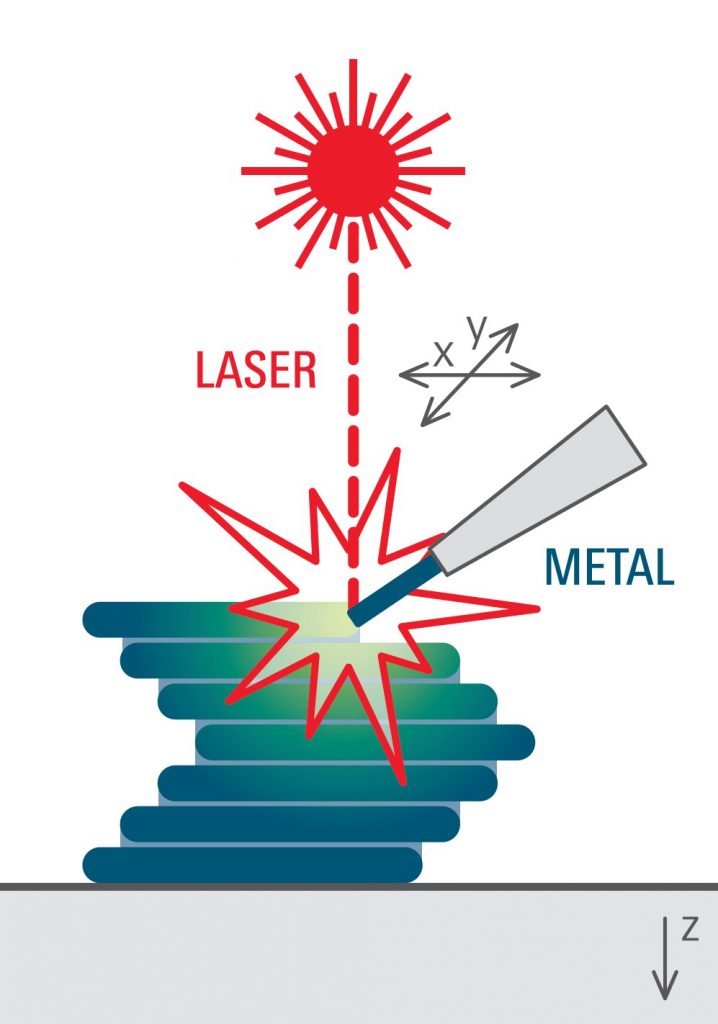

Selective Laser Melting (SLM)

Selective laser melting is a production method which is similar to SLS and focuses on the processing of powdered metallic materials. The method uses the laser to directly melt the metallic powder located in areas that are defined by the shape of manufactured part’s layer. As soon as one layer is complete, the printing platform lowers by one printing layer, and another layer is applied, and the entire process repeats itself till the whole part is complete. More >>

Machines in the consortium: TruPrint 1000, SLM 280HL, EOS M290

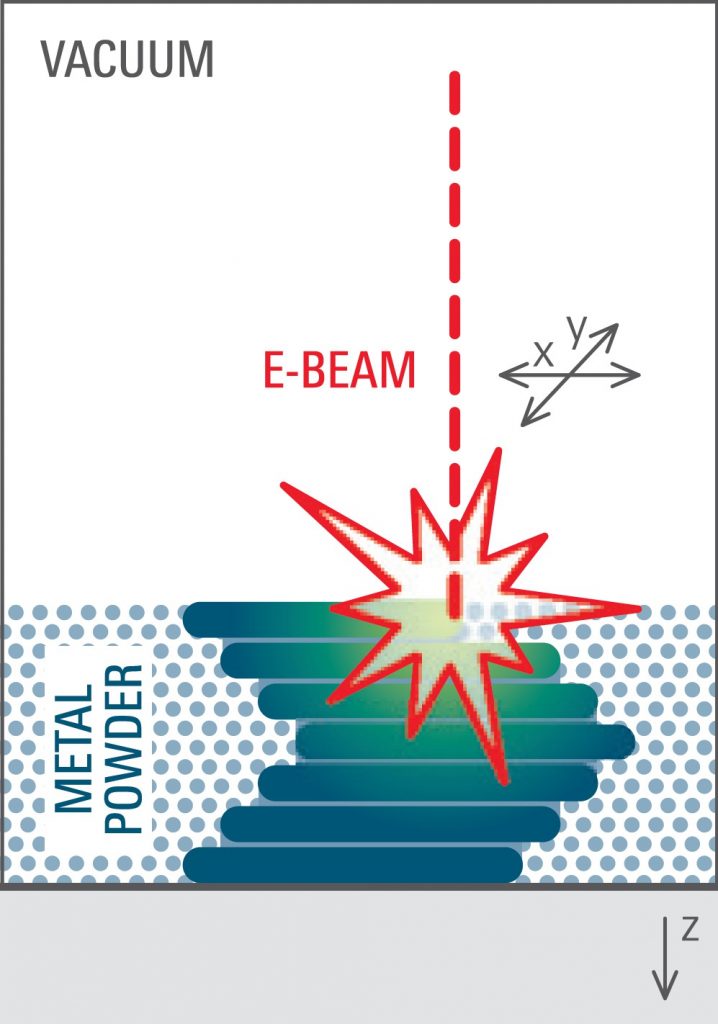

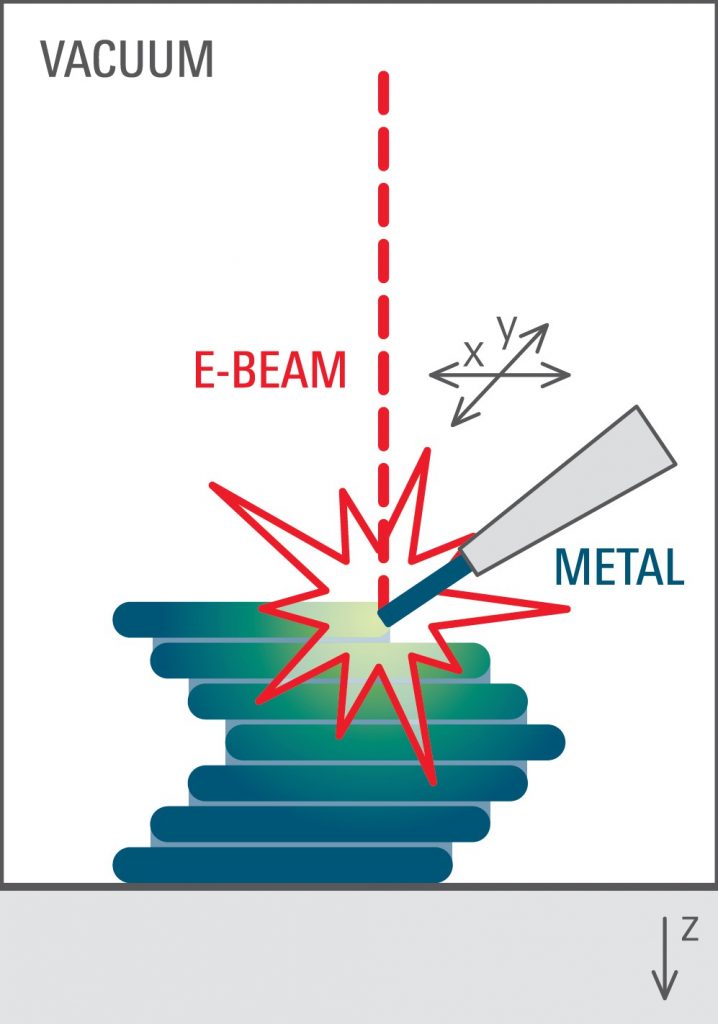

Electron Beam Melting (EBM)

This printing method is based on a complete melting of a metallic powder or wire using an electron beam. To ensure a direct flow of electrons, reducing its unwanted collisions with gases in the atmosphere, a deep vacuum in the whole printing area must be assured. This makes it possible for reactive metals such as titanium and its alloys to be printed. If a powder is used, then this method highly resembles the Selective Laser Melting (SLM) method.

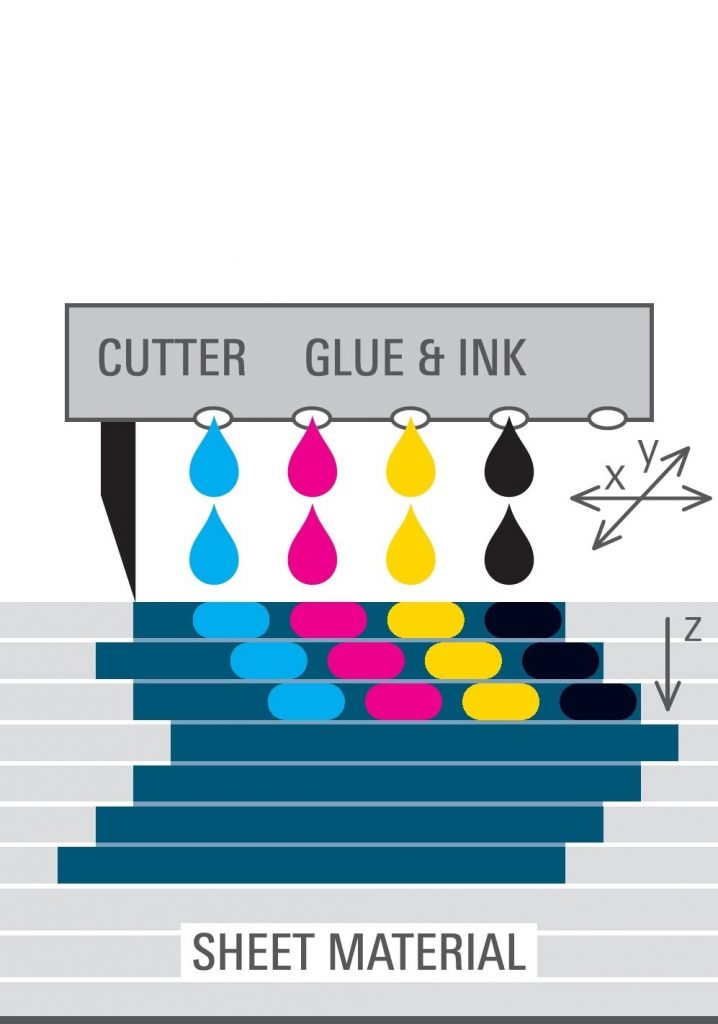

3D printing using other materials

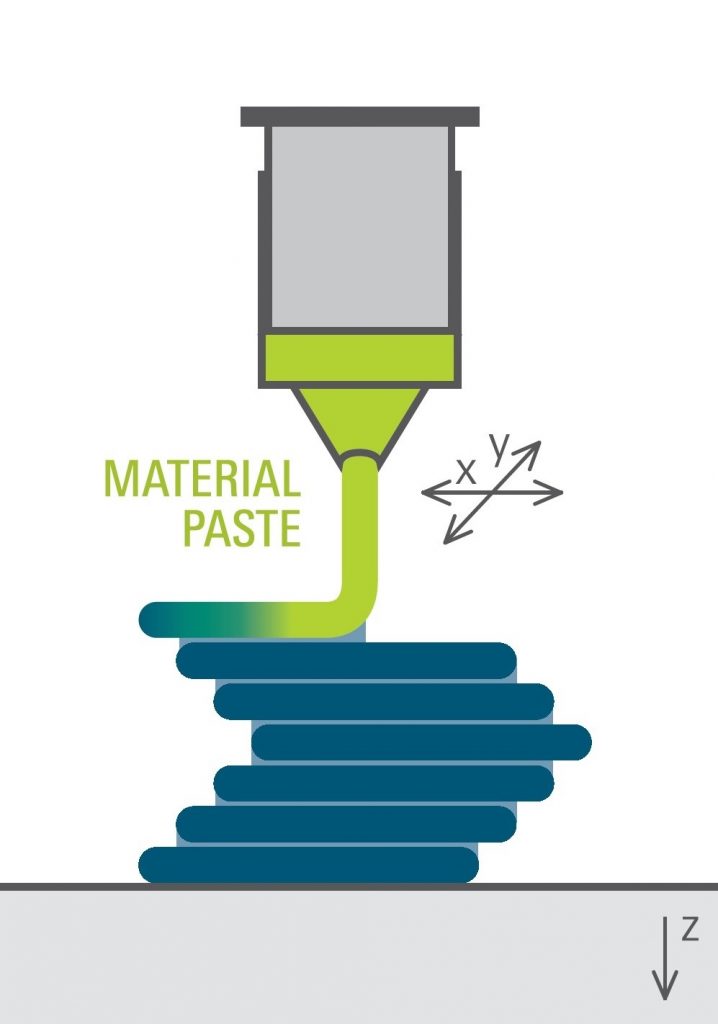

Paste Extrusion Modelling (PEM)

This technology uses dense pasty material for printing. During the process, the material is pushed out layer-by-layer, using high pressure. Each layer solidifies immediately after application. This printing method has a great potential for experimental applications in art projects, materials research and custom-made decorations. Its simple construction makes it a safe solution for educational purposes and children projects.

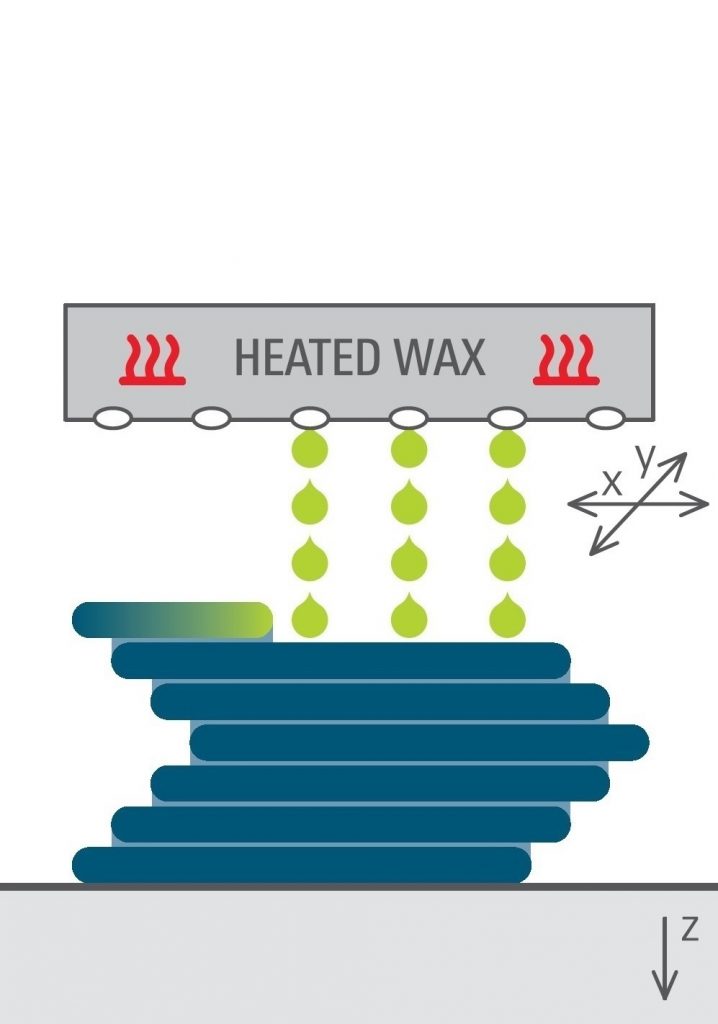

Drop On Demand (DOD)

This is a method where the material is melted in the printing head, creating droplets that are gradually applied on a printing support or on a previous layer. The melting heat builds up pressure that expels the droplets of the material from the printing head. This method is typically used to create wax models for jewellery making.

Schematic images of 3D printing technologies are used with the permission of Prof. Steffen Ritter.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the