This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

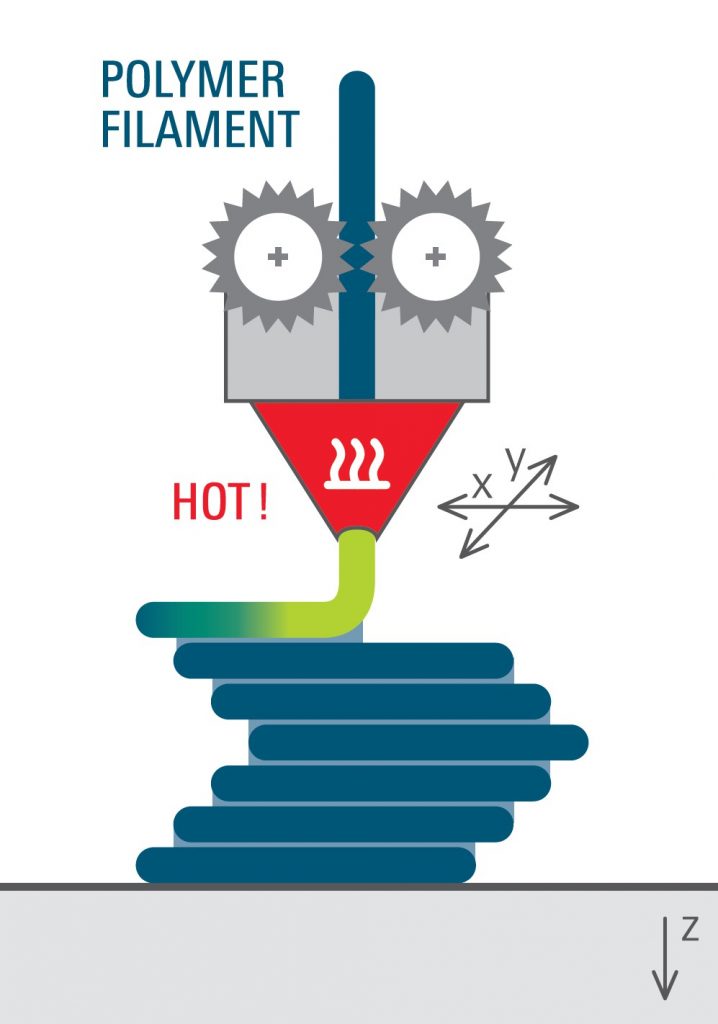

Fused Deposition Modelling (FDM)

Fused Deposition Modelling technology is based on melting the plastics in the form of filaments inside an extrusion head. The head pushes out the molten material to a support, gradually applying a very thin layer in two axes in a plane determined by the horizontal cross-section of the future product. After the application of one complete layer, the extrusion head increases layer thickness in the vertical axis, re-continuing the gradual application process until the completion of the entire product.

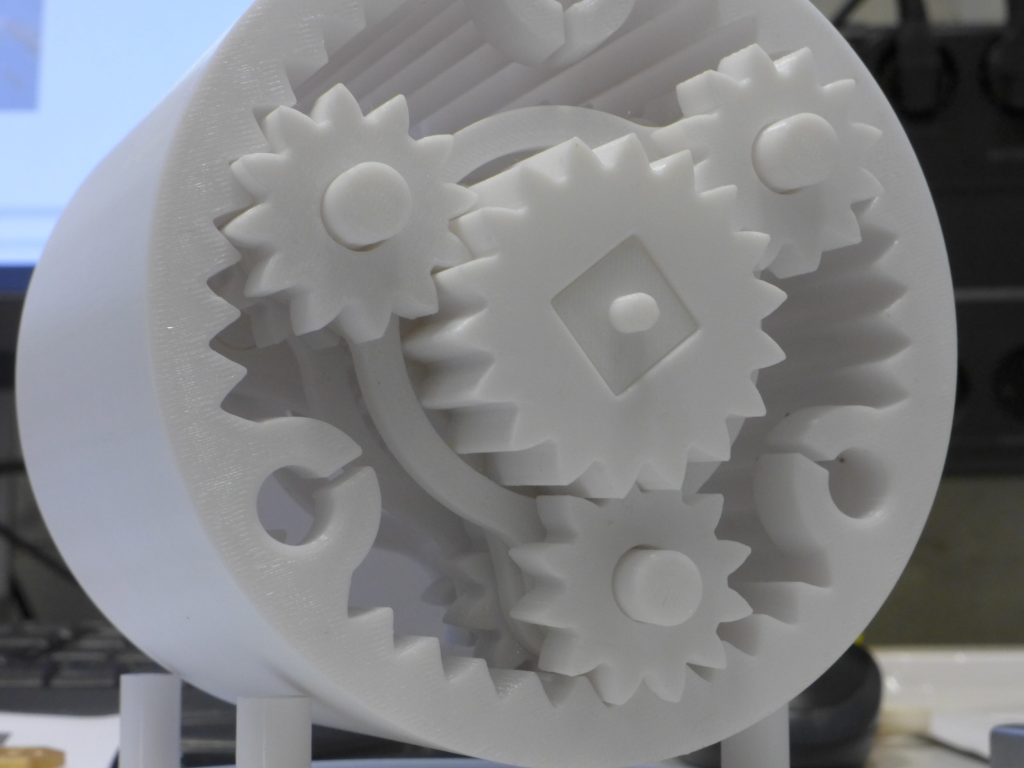

Prusa i3 MK3s

The latest model of the FDM printer by Průša can compete with professional printers such as Fortus 450mc. Its low price makes it a popular choice for everybody who needs to prototype and create robust small-sized prints.

Product examples:

Technical parameters

| Building space | 250 x 210 x 210 mm | |

| Layer thickness | 0,05+ mm (adjustable) | |

| Available materials | ABS | |

| PLA | ||

| PET | ||

| HIPS | ||

| FLEX | ||

| ASA | ||

| metal composites such as Bronzefill | ||

| PP | ||

| Carbon fibre composites | ||

| Nylon | ||

| T-Glase | ||

| wood composites such as Bamboofill |

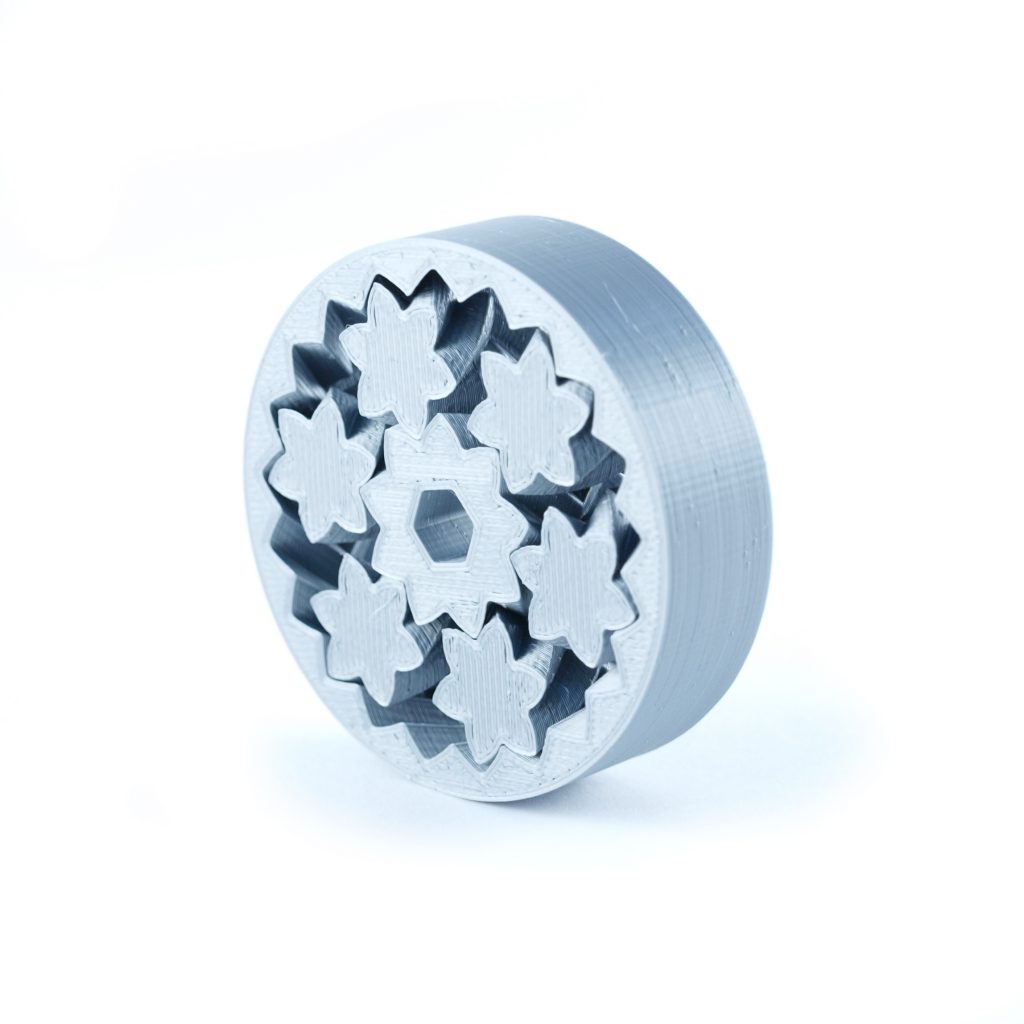

Stratasys Fortus 450mc

A production system that enables the printing of high-precision parts from different types of thermoplastic materials. The resulting parts surpass the products of other 3D printing methods mainly by mechanical properties, and thermal and chemical resistance. The great advantage is the possibility to decrease the weight of the model using a honeycomb internal structure.

Product examples:

Technical parameters

| Building space | 406 x 355 x 406 mm | |

| Layer thickness | 0,127/0,178/0,254/0,330 mm ( depends on the type of material) | |

| Available materials | ABS-M30 | available in 6 colours, excellent mechanical properties |

| ABS-M30i | biocompatible material | |

| ABS-ESD7 | antistatic material | |

| ASA | UV stable material with the best viewing properties | |

| PC-ISO | biocompatible material with high strength | |

| PC | excellent mechanical properties and thermal resistance | |

| FDM Nylon 12 | material with maximum toughness | |

| ULTEM 1010 | top chemical, mechanical and thermal resistance | |

| ULTEM 9085 | excellent chemical, mechanical and thermal resistance |

Schematic images of 3D printing technologies are used with the permission of Prof. Steffen Ritter.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the