Vyhledávání

Analytical methods

Analytical methods constitute an indispensable part of not only R&D in new materials and technologies but they also are closely associated with the optimization of existing solutions. They find application in forensic engineering, in disciplines such as material or part failures.

In the NCC for MATCA, the main disciplines include analytical methods, primarily including microscopy, chemical analyses, and, importantly, the mechanical testing of materials.

Microscopy

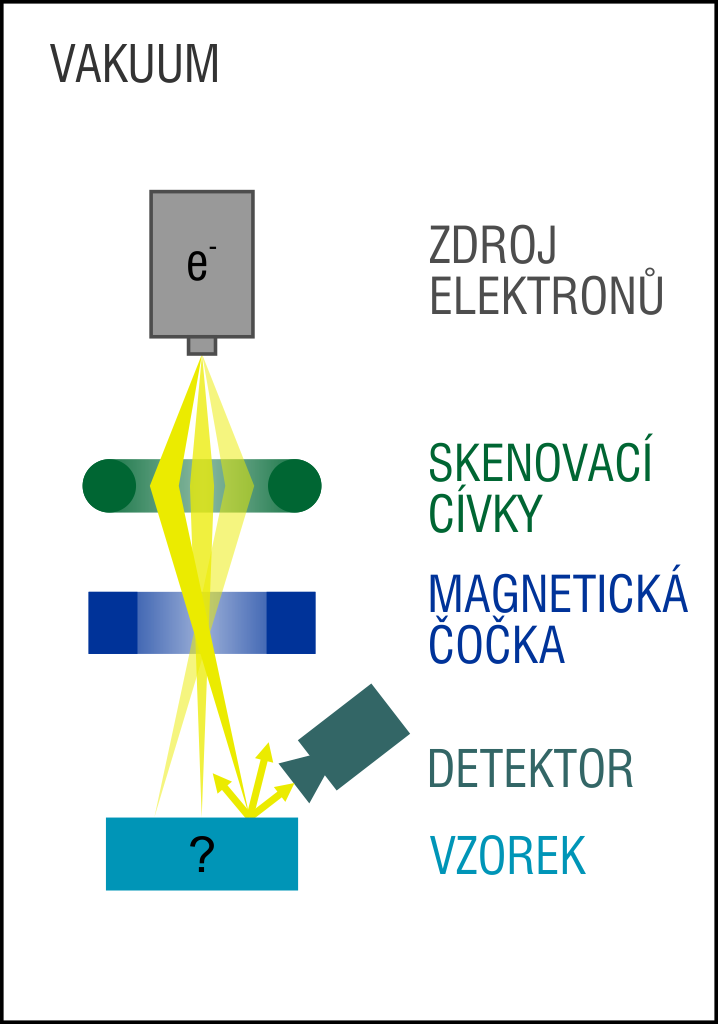

Scanning electron microscope (SEM)

The scanning electron microscope (SEM) is, like any other microscope, an optical instrument which unlike traditional microscopes uses electrons instead of photons as a source of radiation and electromagnetic lenses instead of glass lenses. The entire internal space, the electron beam, and the sample are located in vacuum to prevent electrons from interacting with the atmosphere. To study or analyse a sample’s surface, we use the electron beam-sample interactions to obtain a number of data on e.g. the sample’s microstructure, crystallographic ordering or chemical composition etc. More >>

Available in the NCC for MATCA:

SEM – FEI Quanta 3D FEG, SEM – FEI Phenom, SEM – Tescan MAIA-3,

SEM – FEI/Philips 30XL

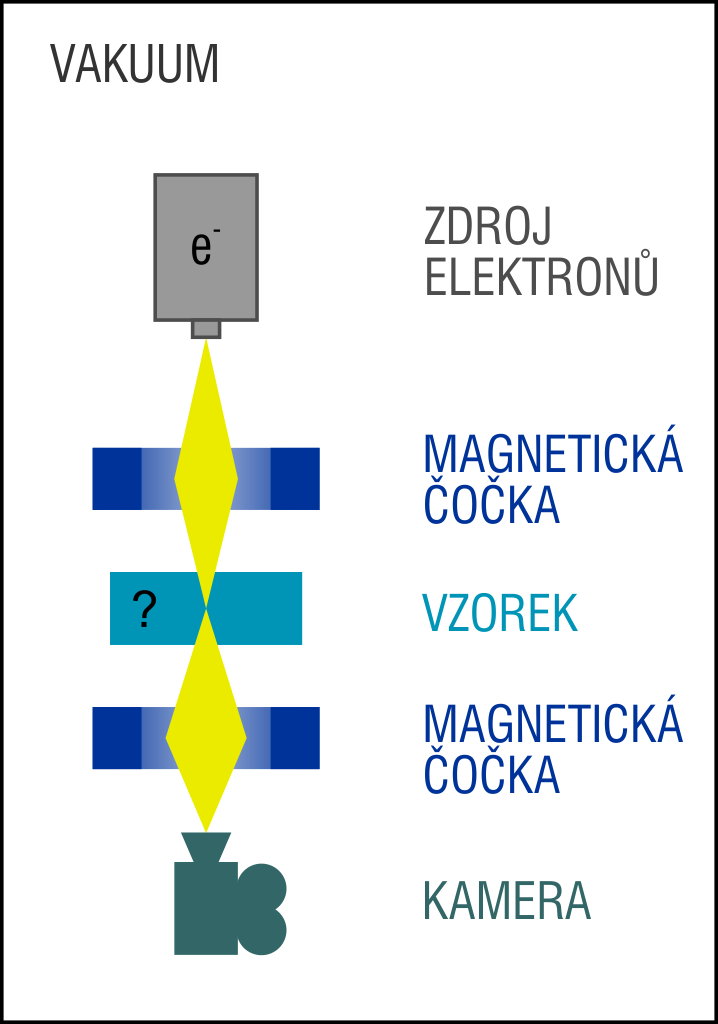

Transmission electron microscope (TEM)

Transmission electron microscope (TEM) enables the observation of thin preparations and the study of their internal structure, the imaging of their individual atoms, and the determination of their chemical composition etc. Like SEM, it also uses an electron beam but it differs in that the light is passed through the sample, and we analyse the electrons that pass through the sample to the other side. More >>

Available in the NCC for MATCA:

TEM – Jeol JEM-1200EX, S/TEM – FEI Tecnai TF20 X-Twin, TEM – FEI Tecnai G2 20

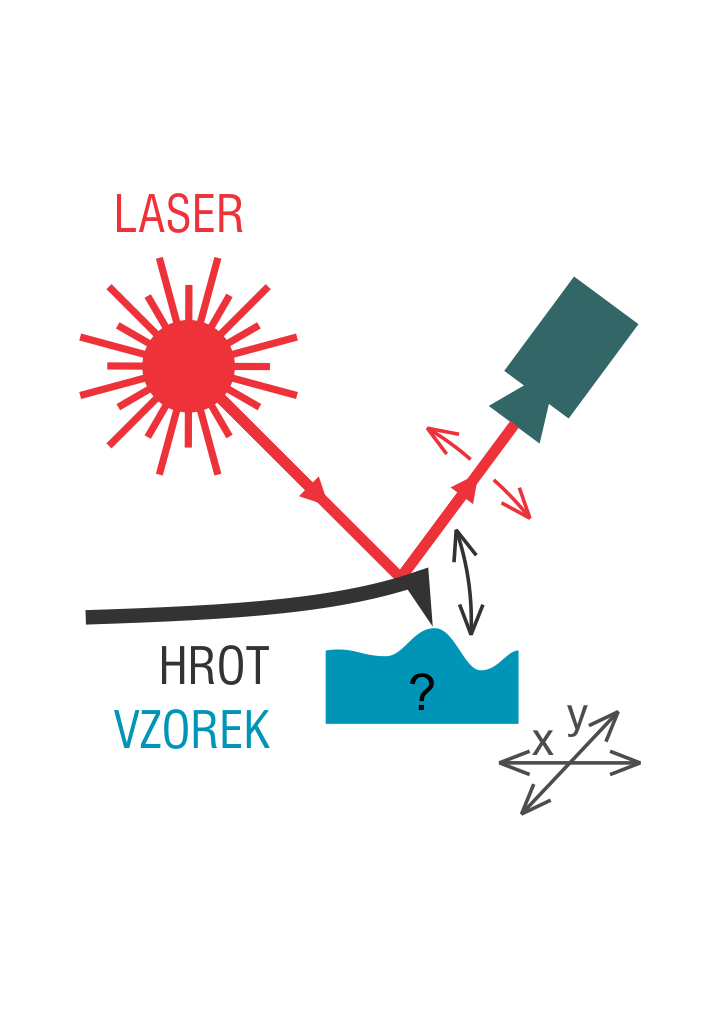

Atomic force microscopy (AFM)

Atomic Force Microscopy (AFM) is a method for obtaining an image using a scanning probe (tip). The tip is placed on a cantilever and moved just over the surface of the studied sample, making a regular raster scan. Due to the irregularities of the surface, the cantilever tip bends slightly; this motion is detected by a laser. The dependence of the bending on tip position gives us surface topography. More >>

Available in the NCC for MATCA:

AFM – Dimension Icon (Bruker), AFM – Explorer (ThermoMicroscopes)

Chemical analyses

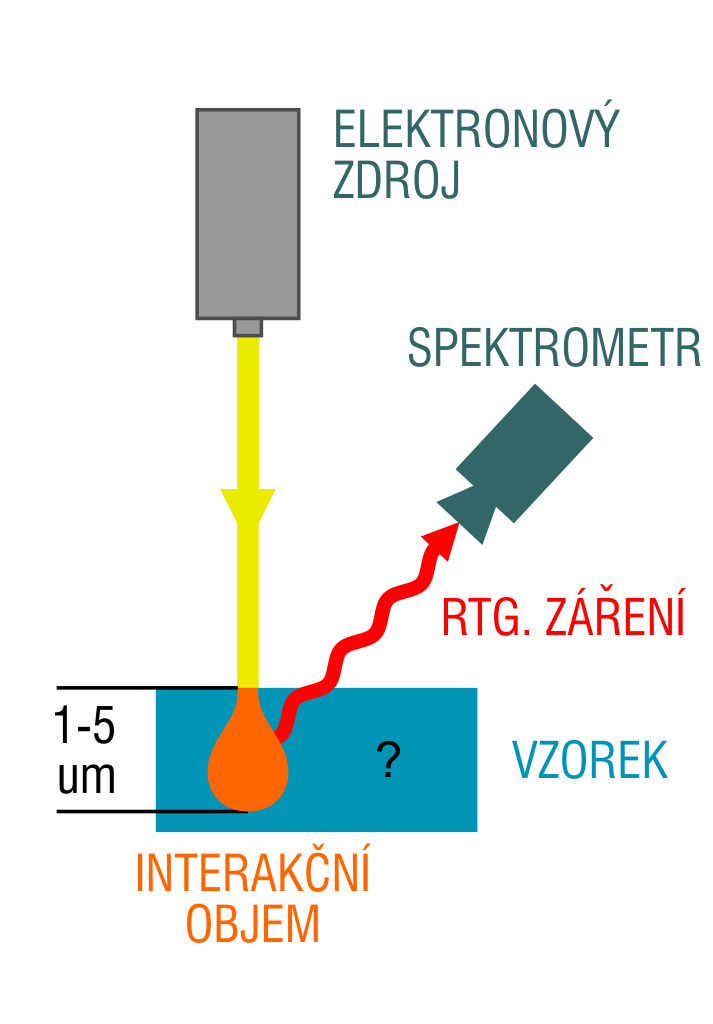

Energy-dispersive X-ray spectroscopy (EDS)

Energy-dispersive X-ray spectrometry (EDS) is an analytical method based on the detection of characteristic X-rays emitted during interactions between an electron beam and the surface of the sample. From energies of the photons emitted in these interactions, we obtain the EDS spectrum, enabling us to determine individual constituent elements of the sample, as well as their quantities. The EDS detectors are usually a part of SEM or TEM. More >>

Available in the NCC for MATCA:

EDS – SEM – FEI Quanta 3D FEG, EDS – S/TEM – FEI Tecnai F20 X-twin

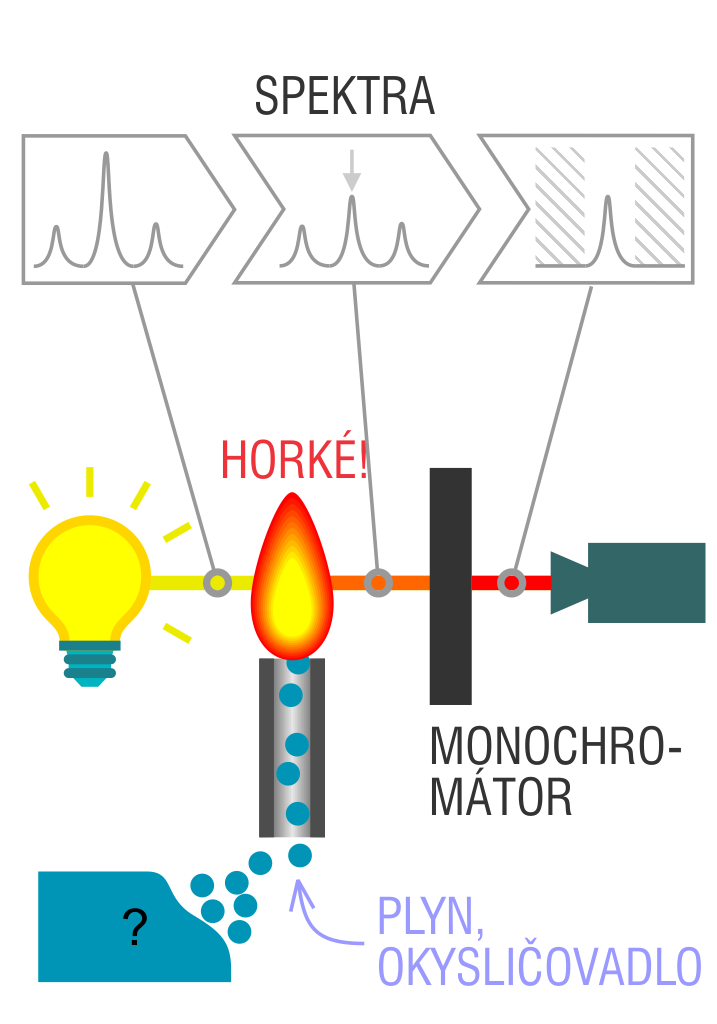

Atomic absorption spectrometry (AAS)

Atomic absorption spectrometry (AAS) is a method of quantitative analysis that uses absorption of radiation by free atoms to determine the content of individual elements in a sample with very high accuracy (hundredths to hundreds of ppm). It should be noted that AAS is a comparative method that compares the measured values with a reference value given for a specific element. A material sample is first transformed to aerosol using the atomization process and then it is fed to the burner. The flame is passed through with a radiation beam, causing the beam to weaken. This weakening, typical of a given element, corresponds to the concentration of the element in the material. More >>

Available in the NCC for MATCA:

AAS – spektrometr Varian AA240

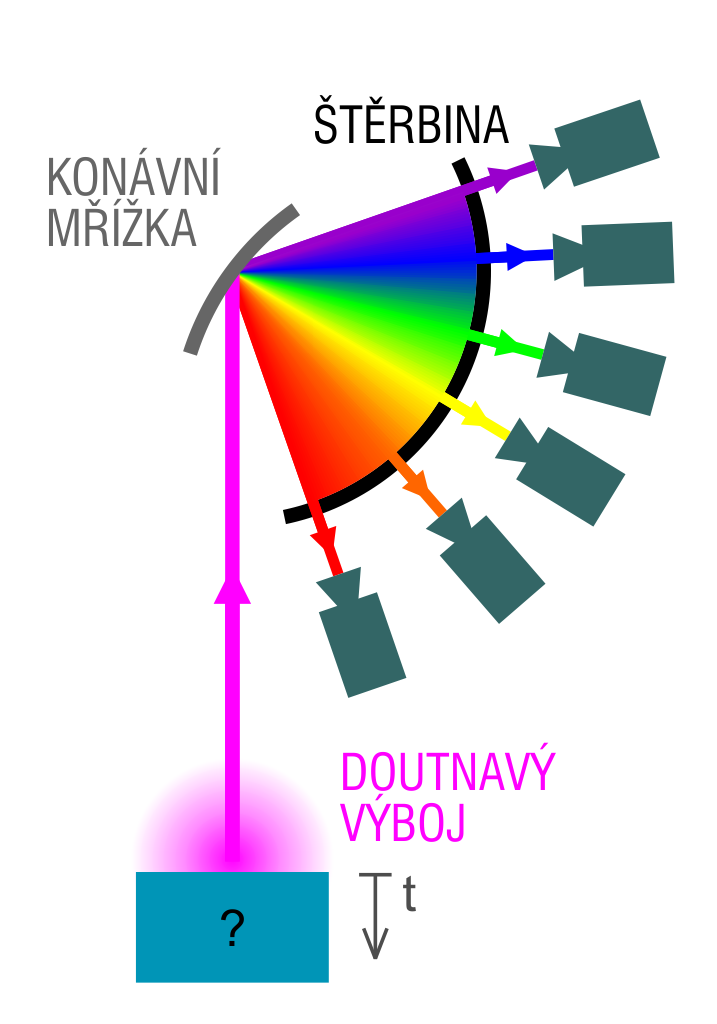

Glow Discharge Optical Emission Spectroscopy (GDOES)

Glow Discharge Optical Emission Spectroscopy (GDOES) uses the so called Grimm lamp as a source of charge. Inside this lamp, the sample is placed on a cathode, an anode is a hollow copper tube, and the work space inside the lamp is filled with inert gas. By supplying high voltage between the cathode and anode, a glow discharge is ignited. The resulting radiation, after it leaves the lamp, is dispersed to a spectrum, which is evaluated by the detector. This creates a concentration profile, which identifies the constituent elements and their quantity. More >>

Available in the NCC for MATCA:

GDOES – spektrometr GDA750HR (Spectruma Analytik GmbH)

X-ray photoelectron spectroscopy (XPS/ESCA)

X-ray photoelectron spectroscopy (XPS), also known as electron spectroscopy for chemical analysis (ESCA), is a method for analysing the surface of solids. The analysed sample is irradiated by X-rays, causing photoelectrons to be emitted from the surface of the sample. Using a system of electromagnetic lenses, the photoelectrons are directed into the analyser, at the other end of which there is detector. The detector analyses the binding energy and photoelectron peak intensity, providing us with information about the representation of specific elements, their quantity and chemical state. In simple terms, ESCA/XPS is a useful technique, as it shows not only what elements are represented in the surface of a sample, but also to which other elements they are bound. More >>

Available in the NCC for MATCA:

ESCA/XPS – spektrometr ADES 400 (VG Scientific), ESCA/XPS – spektrometr AXIS Supra (Kratos Analytical Ltd)

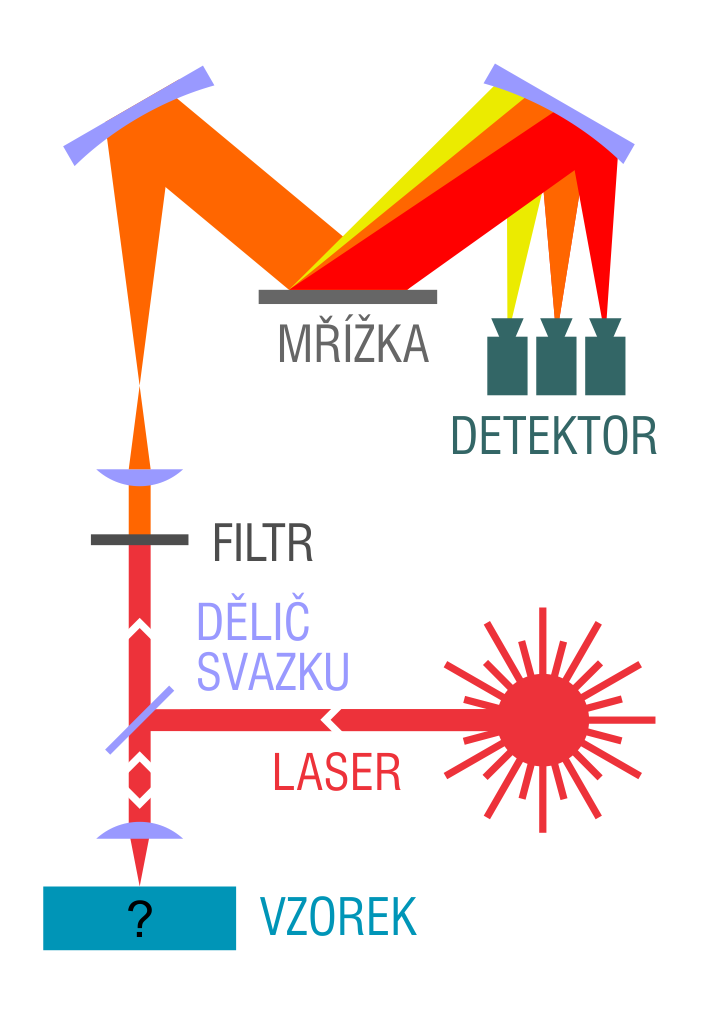

Raman spectroscopy

Raman spectroscopy is an effective and non-destructive method for analysing the chemical composition of a material. This method uses the so called Raman effect, which is the inelastic scattering of monochromatic radiation on a material particle that takes place during an interaction of a laser beam and the atoms of a studied material. The Raman effect fully describes the process of the wavelenght shift from exciting radiation (emitted by the source of a monochromatic radiation) to scattered radiation (from a sample). As each substance shows its characteristic wavelenght shift, it is possible to exploit this effect for the identification of the chemical composition of a sample material in various states; the determination of the quantity of constituent elements or the analysis of the structure. More >>

Available in the NCC for MATCA:

Raman – Micro-Raman spectrometer RM 1000 (RENISHAW), Raman – In-Via Reflex Raman Microscope (RENISHAW)

Mechanical testing

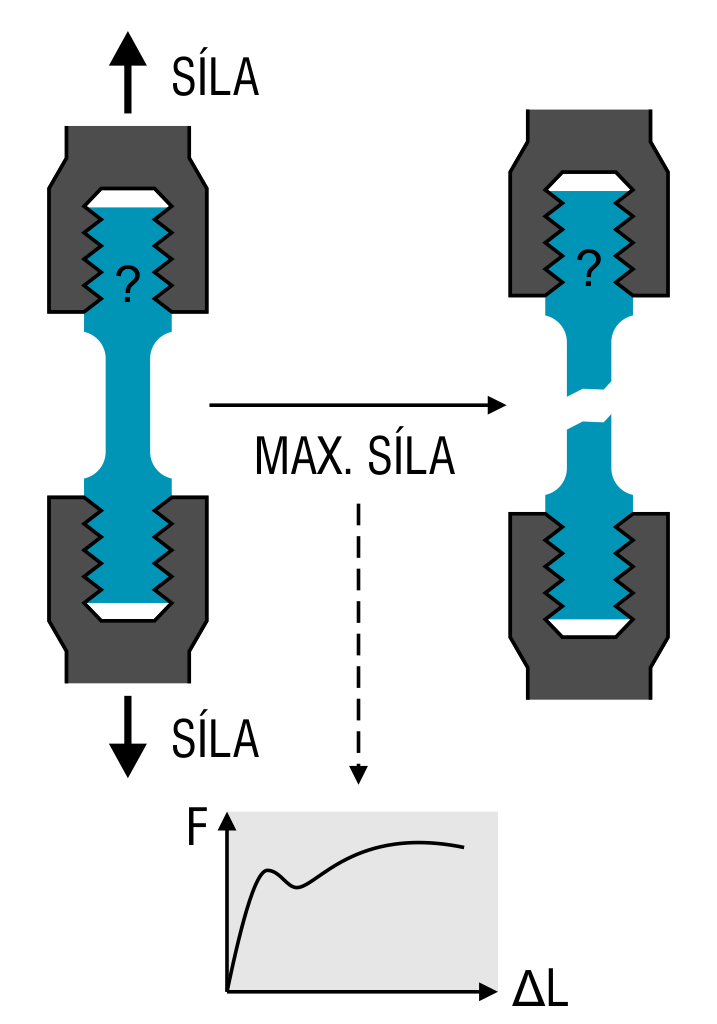

Tensile testing

Tensile testing is one of the static mechanical tests and constitutes one of the main instruments for ensuring mechanical properties of materials. By subjecting the specimen to the so called “controlled tension until failure”, we obtain a chart showing the dependence of strength on sample elongation. The chart enables us to determine the basic mechanical properties of a material, including yield strength, ultimate tensile strength, ductility or contraction. Tensile testing also allows us to determine Young’s modulus of elasticity in tension or some technological properties such as plasticity reserve. More >>

Available in the NCC for MATCA:

INSTRON 1362 Deformation mechanical machine, INSTRON 5882 Quasi-static deformation machine

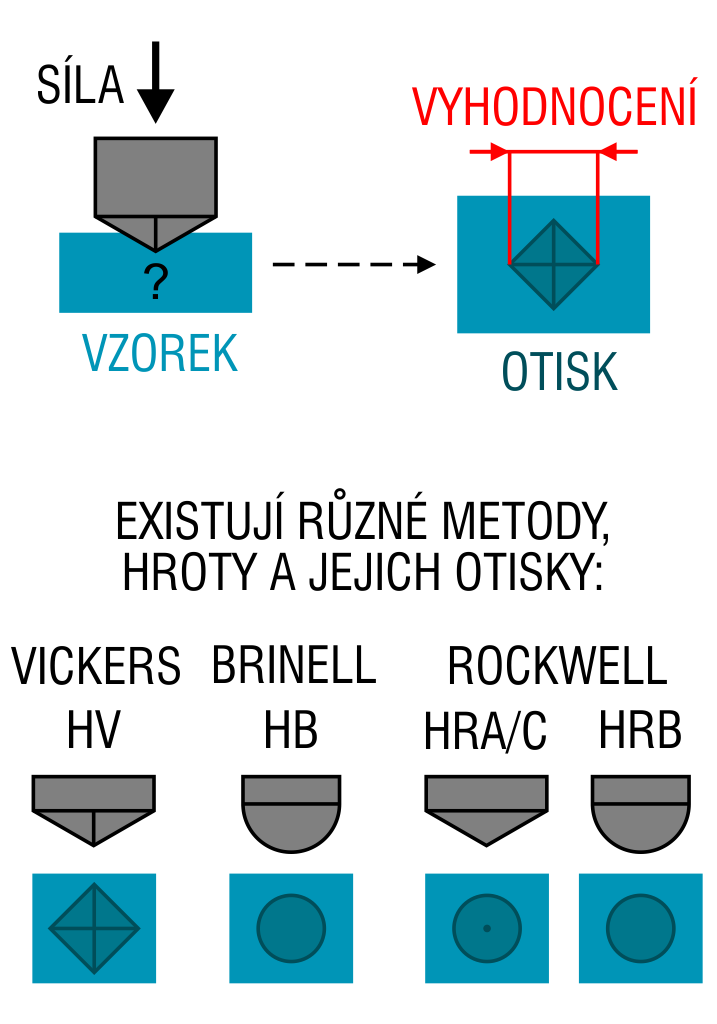

Hardness measurement

The resistance of a material against the penetration of an indenter, i.e. material hardness, can be determined using various methods depending on the type of the tested material. In general, indenter (typically ball-, cone- or pyramid- shaped object) penetrates the surface of the studied material using calm force, dynamic shock or indentation. The resulting material hardness is the dependence of load force on impression or indentation depth. More >>

Available in the NCC for MATCA:

Struers Duramin 2 micro hardness tester

Material fatigue testing

Material fatigue is a process during which mechanical parts are damaged by stresses significantly lower than is their material strength determined by a static test. This is because most parts and constructions are stressed dynamically, which means they are exposed to varying cyclic loading that can lead to the initiation of fatigue cracks, or, in the worst case scenario, to a fatigue fracture. That’s why fatigue tests where a sample of a material is stressed dynamically for a pre-determined number of cycles are a great opportunity to study fatigue damage The outcome of the test is a chart showing the dependence of stress on the number of cycles until damage, known as the Wöhler curve or the S-N curve. More >>

Available in the NCC for MATCA:

INSTRON 8872 servo-hydraulic deformation machine

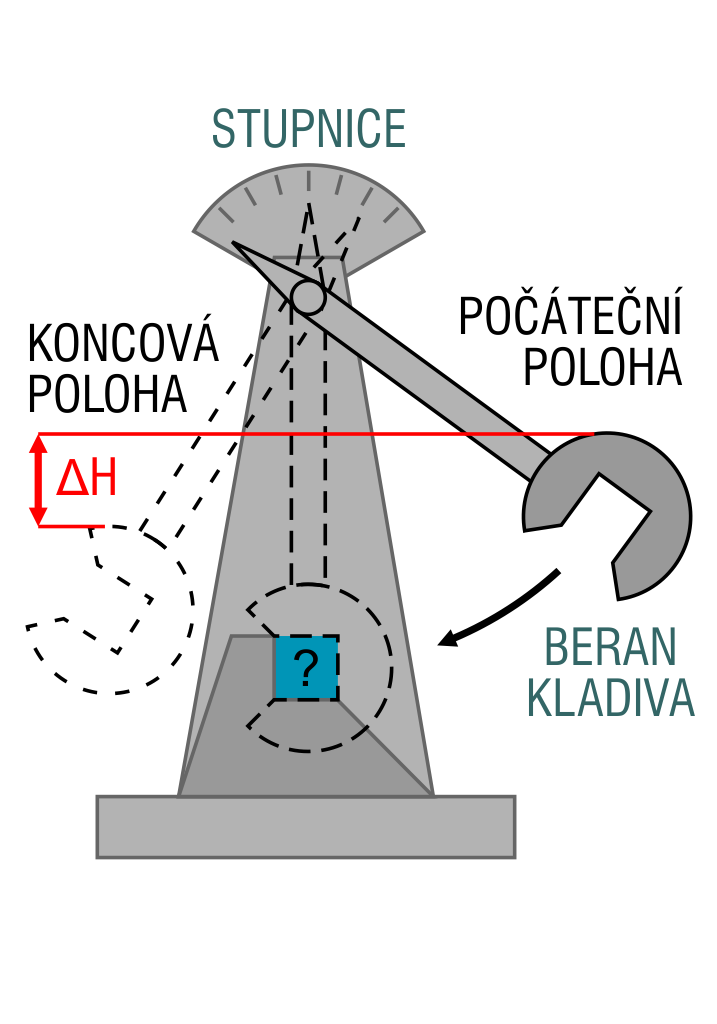

Impact strength test

Impact strength is one of the material’s main mechanical properties and is defined as the resistance of material to fracture damage. The measurement of impact strength starts by placing a specimen into a Charpy hammer working area, and continues by breaking the specimen apart with the hammer. The fractography analysis tells us how the damage occurred, and together with the force needed to break the specimen apart, it gives us information about the material’s fracture behaviour. The impact strength is also linked to a number of technological properties. More >>

This technology is available in the consortium.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the