Vyhledávání

Surface treatment methods

Surface treatment methods significantly improve mechanical, anticorrosive, thermal and other useable properties of the product by modifying its surface or by applying a suitable coating to it.

Plasma coating

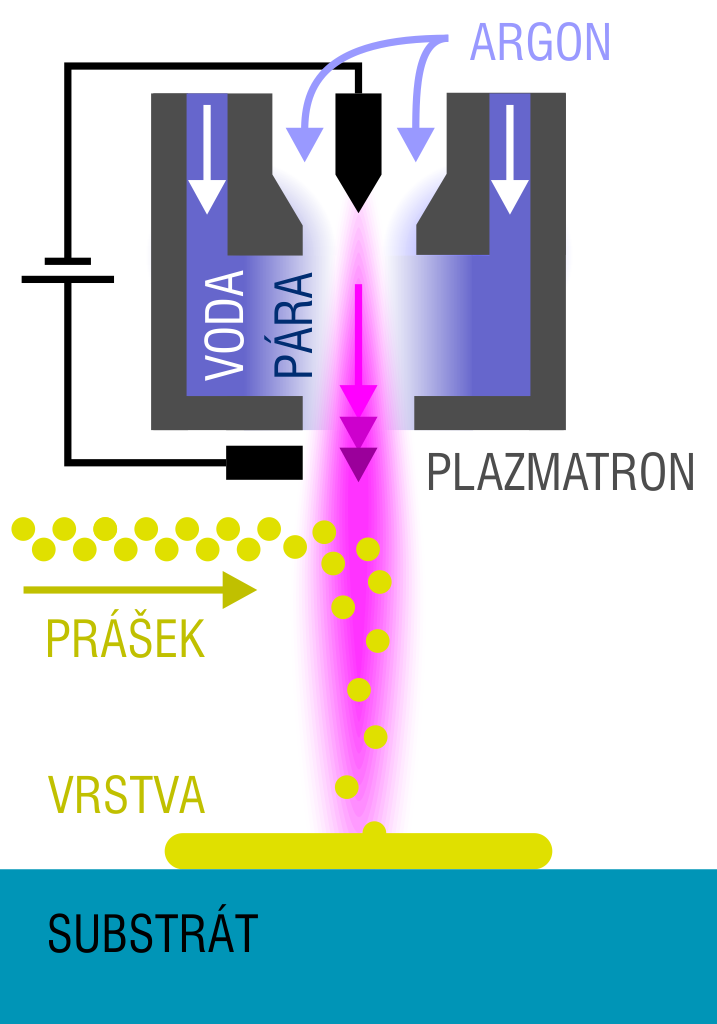

Hybrid water-stabilized plasma spraying

Hybrid water stabilized plasma spraying (WSP-H) is a novel hybrid technology using a plasma torch that combines the benefits of a classic gas stabilized DC arc torch with a uniquely designed water duct. More >>

Available in the NCC for MATCA:

WSP-H 500

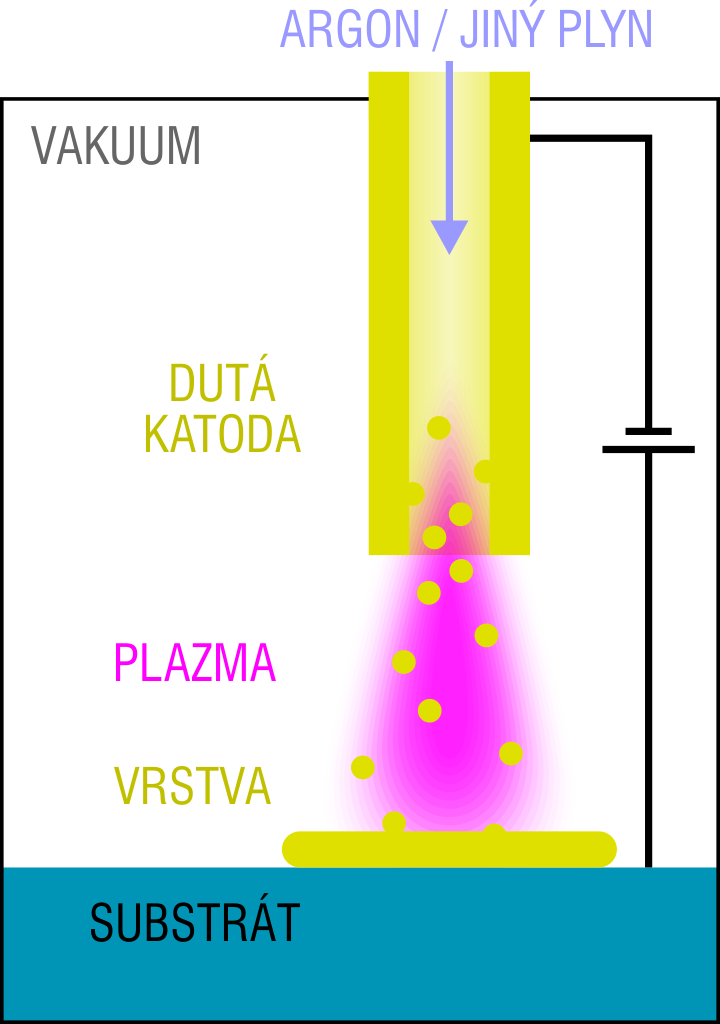

Hollow cathode

A hollow cathode deposition system is based on hollow cathode magnetron sputtering in the reactive atmosphere of the operation gas. The hollow cathode provides a high degree ionisation that causes not only an intensive cathode sputtering process but also the ionization of a reactive gas, and the subsequent improvement of the properties of the deposition layer induced by an increased bombardment of the substrate. More >>

Available in the NCC for MATCA:

more than 5 devices

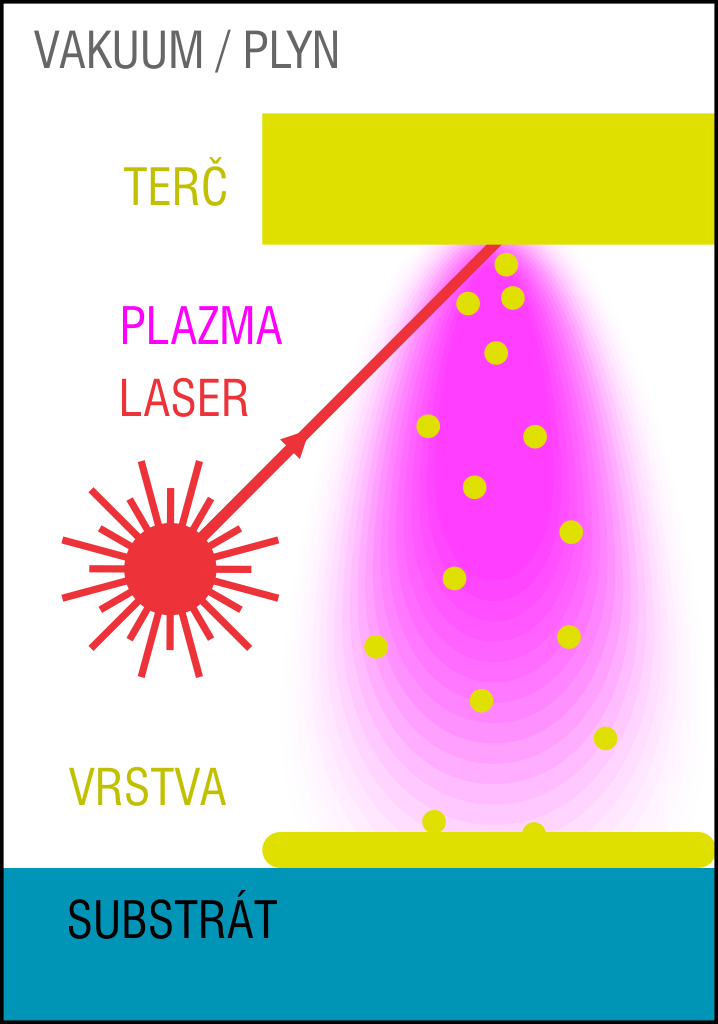

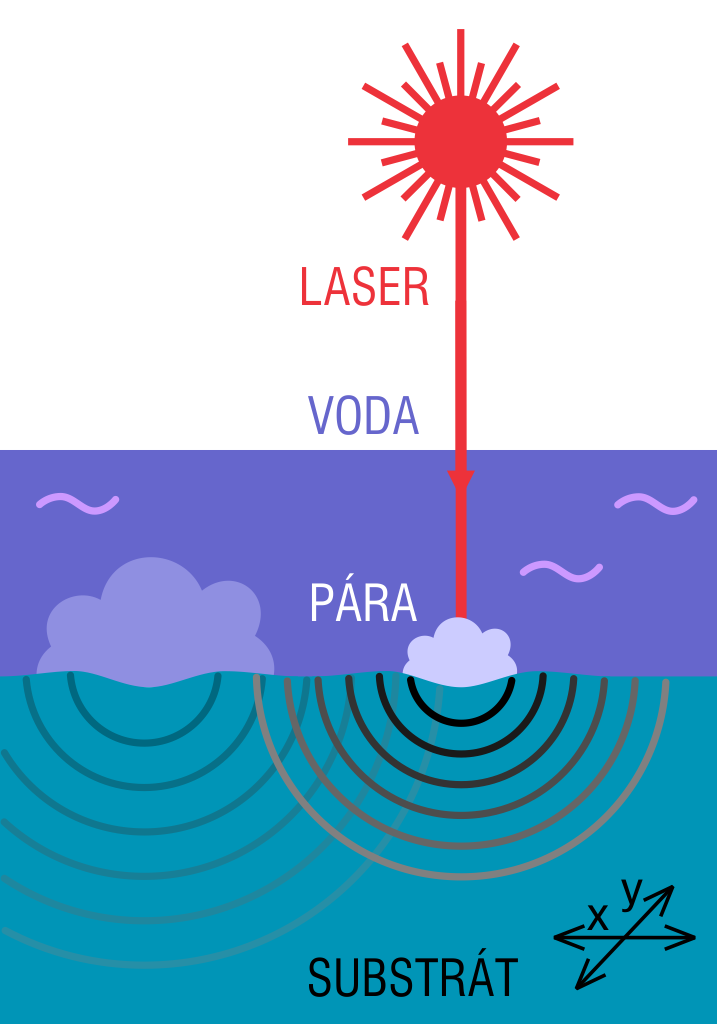

Pulse laser deposition

Pulse laser deposition (PLD) is a method for creating inorganic and – to a limited extent and subject to some modifications – organic thin layers from materials with a complex elemental composition. In its original form, this method was first published in 1965. More >>

Available in the NCC for MATCA:

more than 5 devices

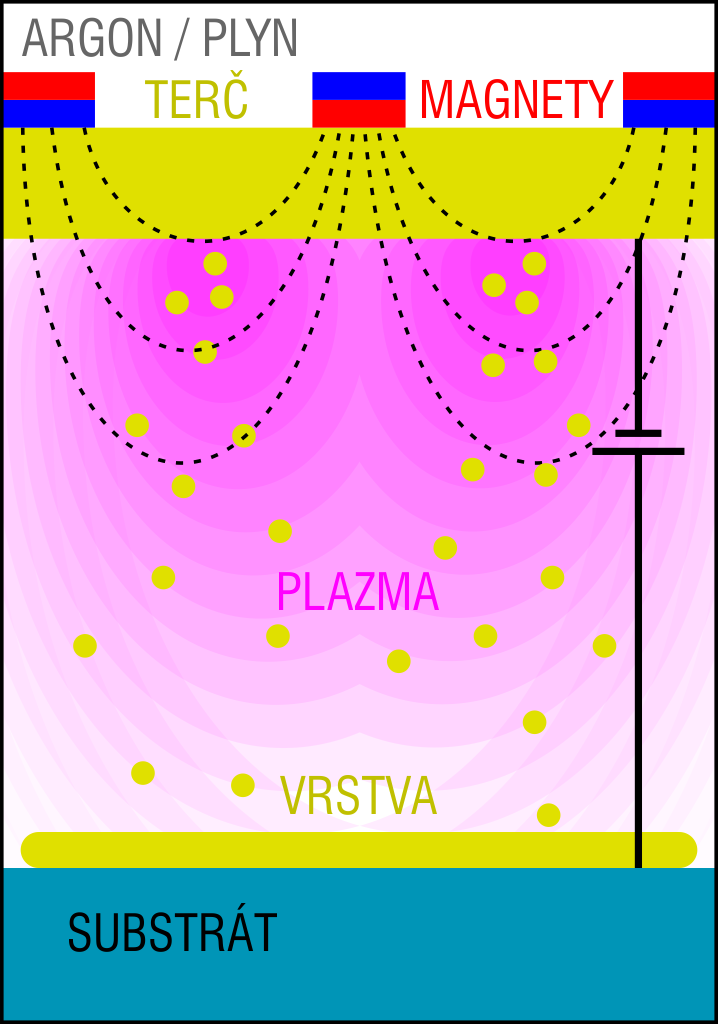

Magnetron sputtering

Magnetron sputtering (MS) is a deposition method that uses targets from a conductive material placed into a vacuum chamber and connected to a high negative voltage. An operation gas (typically an inert gas – such as argon) is fed to the chamber, with the pressure in the chamber maintained in the range of tens to units of pascals. More >>

Available in the NCC for MATCA:

more than 5 devices

Surface treatment using laser

Laser Shock Peening

Laser Shock Peening (LSP) is a process that uses nanosecond high-energy laser pulses to create compressive residual stresses in the material, with nominal depths of up to 1.5 mm. More >>

This technology is available in the consortium.

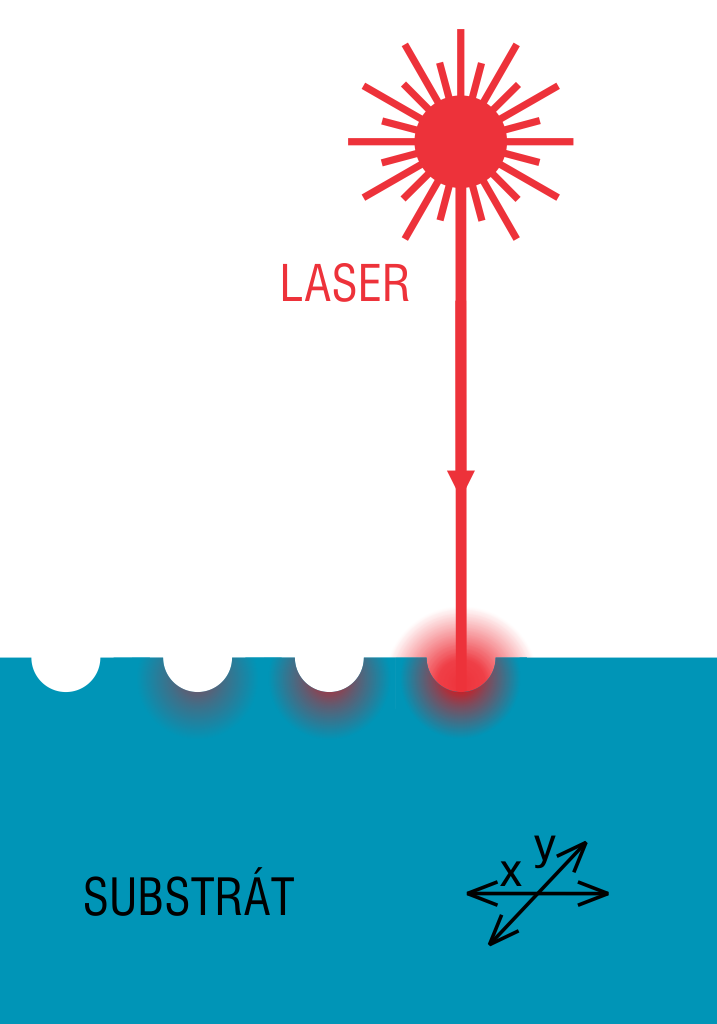

Micromachining

Laser micromachining technology uses a laser beam that is focused on a small area of the machined material, making it heat up to a high temperature at which the material starts to evaporate. More >>

This technology is available in the consortium.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the