This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

Micromachining

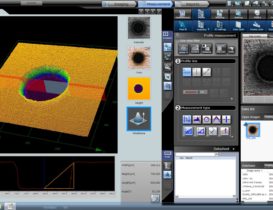

Laser micromachining technology uses a laser beam that is focused on a small area of the machined material, making it heat up to a high temperature at which the material starts to evaporate. Due to short and intense laser pulses, a minimum thermal effect is exerted on the surrounding material. Laser micromachining is typically used for cutting, drilling, engraving, and laser cleaning. Drilling and cutting can be performed for minimum diameters below 30 µm.

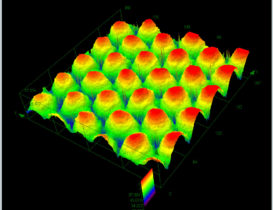

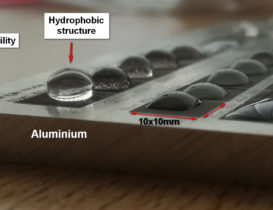

Another application is the fabrication of functional surfaces where suitably created surface nano- and microstructures can lead to the modification of surface properties such as friction, hydrophobicity and hydrophilicity of the surface, anti-bacterial properties etc.

In order to increase the speed and improve the efficiency of laser micromachining, it is possible to employ multibeam machining processes that allow us to change the number, size, shape and distribution of laser beam intensities freely even during the machining process.

This technology can be used with metals, plastics, ceramics, and composite and other materials.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the