This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

Pulse laser deposition

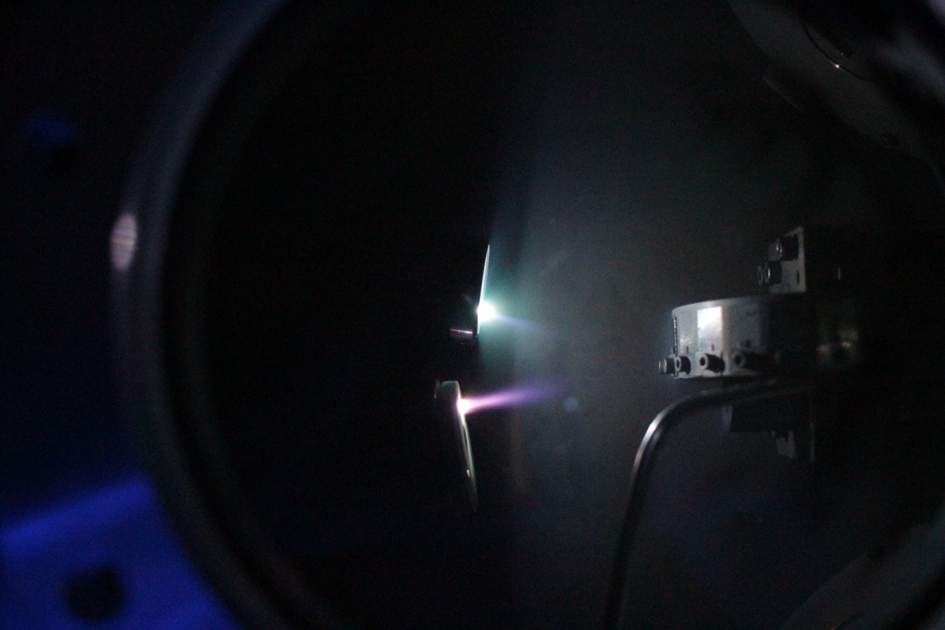

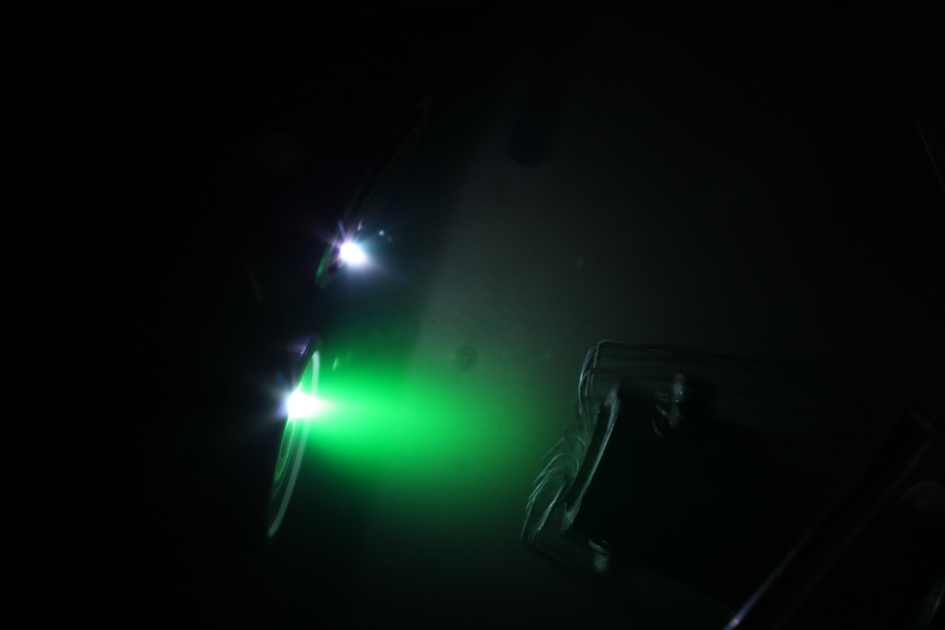

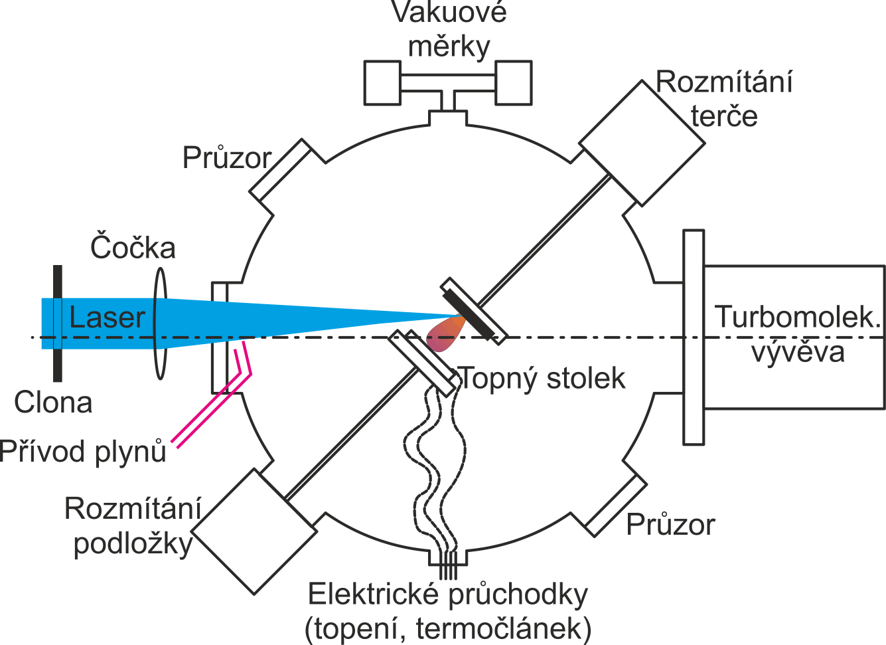

Pulse laser deposition (PLD) is a method for creating inorganic and – to a limited extent and subject to some modifications – organic thin layers from materials with a complex elemental composition. In its original form, this method was first published in 1965. After a target is irradiated by a pulse laser (typically excimer and solid state laser), its material is ablated in a vacuum chamber, turning the target into a plasma cloud. The target typically takes the form of a disc (10 to 50 mm in diameter, a few millimetres thick), but also the form of a long cylinder where the radiation is focused on the rotating side of the cylinder.

The ablated material can be captured on a support (substrate), creating a thin layer with thickness from one molecule to tens of micrometres. The physical properties of the layer can significantly be influenced by the conditions applied during the deposition process, such as substrate temperature, gas pressure (reactive or inert), support/target distance, spot size of the beam on the target, and laser radiation density at the target.

The traditional experimental set up includes a vacuum deposition chamber of stainless steel. In order to prevent a narrow groove from being carved into the target and to avoid overheating in one spot, the target is designed to rotate, making a precess movement, resulting in the material being worked away from the intermediate ring. The beam is focused by a lens (ideally by an aspherical lens) or using a lens system of fused quartz glass (focal distance of 150 to 350 mm), hitting the target at an angle of 45°.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the