Vyhledávání

Laser Shock Peening

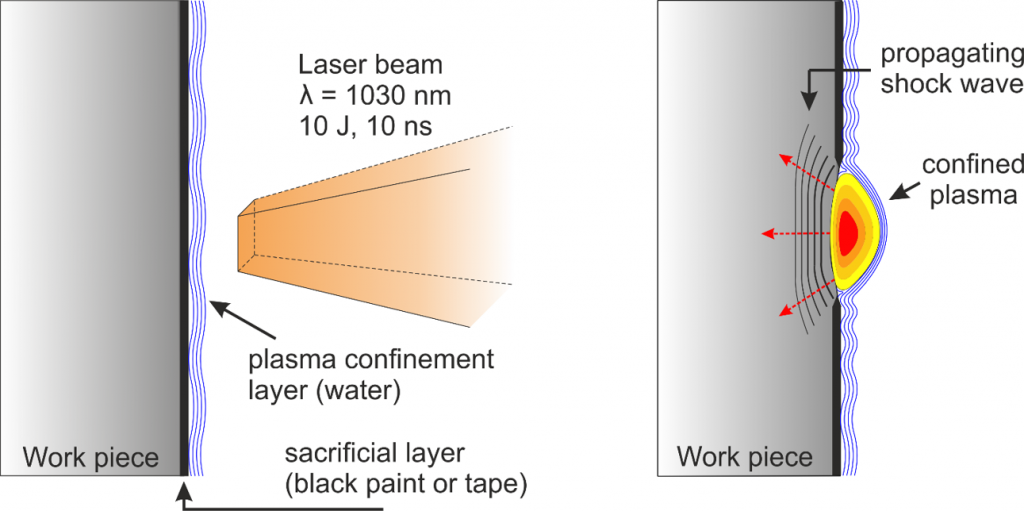

Laser Shock Peening (LSP) is a process that uses nanosecond high-energy laser pulses to create compressive residual stresses in the material, with nominal depths of up to 1.5 mm. Prior to an impact, the laser pulse penetrates a thin water layer, ablating the absorption layer (black sellotape), covering the surface of the treated material. This creates a fast expanding localised plasma that due to a strengthening effect of the water layer reaches the pressure of up to several GPa.

The material is penetrated by a pressure wave, which causes the plastic deformation of the material’s surface layer, resulting in the creation of compressive residual stresses. The depth and the strength of the stresses depends primarily on laser power density, the type of material and sample thickness. For hard materials, a problem can occur when the generated pressure fails to exceed the yield strength.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the