This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

Hardness measurement

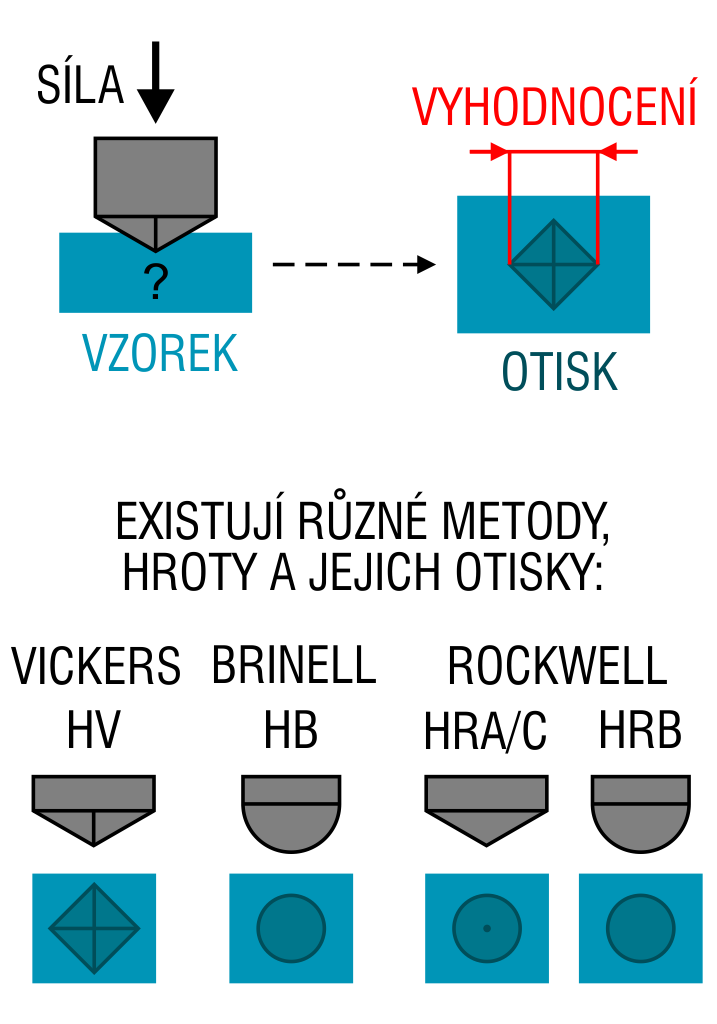

Hardness means resistance of the surface against localized deformation by an indenter (penetration by a foreign body). It is a combination of a number of properties of the studied mass, including, primarily, elastic properties, brittleness and plasticity, physico-chemical properties, and sometimes other. Hardness has no physical definition.

Material hardness is determined using another body called indenter. The properties of the indenter must have sufficient qualities, so that we can exclude its plastic deformation, and limit, as much as possible, its elastic deformation. Therefore, we usually select an indenter with a high value of flexural modulus (hardened steel, sintered carbides).

Generally, there are several criteria, according to which hardness tests can be divided into; most often they are distinguished according to the method of loading: static – specimen (indenter) is impressed into the tested surface by calm force; this is the most common method due to its simplicity and easy reproducibility while maintaining high precision measurement, the other is dynamic – indenter penetrates the tested surface as a result of a vertical impact. Further, we can divide the tests according to the method of material deformation during testing into plastic tests (during testing, a permanent impression is made into the tested surface) and elastic tests (there is no plastic deformation during the test).

The most commonly used testing methods are penetration tests (Brinell, Rockwell and Vickers).

Brinell hardness

Using the Brinell test, hardness is determined by impressing a steel or hard metal ball of fixed diameter (D ) into a specimen using a predetermined test load (F) acting perpendicular to the surface of the specimen for a predetermined time. Then, following force withdrawal, the diameter of the impression is measured.

The ball diameter is standardized and it is selected depending on the thickness of the measured material. The minimum thickness of the tested material is set to be 10times more than the impression depth. Otherwise, the test might be influenced by the hardness of the supporting structure. The load force is selected according to ball diameter. The load time depends on the structure of the material. Softer materials are loaded longer. The load time for ferrous alloys is between 10 and 15 seconds, and 10 s to 3 minutes for non-ferrous metal alloys.

The accuracy of the measurement depends on the correctly measured imprint. For the Brinell test, the imprint measurement is rather imprecise. The imprint is sometimes not very well defined and is non-symmetrical. The diameter of the imprint is also greatly influenced by the material indrawn along the edge of the impression (for non-hardened materials) or wall formation (for hardened materials). The cause of another error is the deformation of the impressed steel ball, which makes the steel ball unsuitable for materials harder than 400 HB; a sintered carbide ball is used instead.

Hardness designation consists of an HB hardness symbol (or HBW for hard metal ball) followed by details on testing conditions, i.e. ball diameter (D), force (F) and load time t. The details are separated with a slash (e.g. HBW 10/3000/10 = 205). There is no accurate system for converting the Brinell results into other hardness systems.

Rockwell hardness

Rockwell hardness is determined with a Rockwell hardness tester and is calculated as the difference between the impression depth of a body (steel ball, diamond cone) that was impressed twice in one location under two different loads (preliminary and total). The purpose of the preliminary load is to eliminate the influence of any irregularities of the surface from the measured depth calculation. The diamond cone has an apex angle of 120° (HRA, HRC). The diameter of the ball is 1.5875 mm (HRB).

The diamond cone or steel ball, which touches the surface of the tested object, is first loaded with a preliminary force of 100 N (the initial position for the impression depth measurement). Subsequently, the load force is gradually increased so that the standard load is achieved within 3 to 6 seconds (such as the preliminary load of 100 N + testing load of 1400 N = total load of 1500 N). Then, the load force is gradually decreased back to 100 N, and the increase (h) of the impression depth is measured so that the depth difference from the initial position under 100 N is obtained. The Rockwell hardness test is fast, simple, and the resulting hit-marks (dents) are very small (max. depth is 0.2 mm). This method is suitable for routine inspections of large production batches and in situations where HB cannot be used.

There are three standardized Rockwell hardness tests used in the Czech Republic. Hardness determined by the tests is designated with the following symbols HRA, HRB, HRC. The Rockwell scale selection (i.e. the selection of the right type of the penetrating body) largely depends on the expected hardness of the tested material. By HRA, hardness is determined using a diamond cone under the overall load of 600 N. This method is suitable for sintered carbides and thin surface layer. By HRB, hardness is determined using a steel ball (B = ball) under the overall load of 1000 N, and is suitable for softer metals. By HRC, hardness is determined using a diamond cone (C = cone) under the overall load of 1500 N; this method is recommended for materials with hardness ranging from 20 to 67 HRC.

Vickers hardness

When measuring Vickers hardness, a diamond regular based right pyramid with a predetermined apex angle is impressed into the tested material using a predetermined force (F), acting perpendicular to the surface of the sample, for a predetermined time. Subsequently, the arithmetic mean of two imprint diagonals is calculated. Test load force usually ranges from 10 to 1000 N. The load time is between 10 to 180 seconds. The loads used are included in the test designation, e.g. HV 30 (HV 30 = 137). Vickers hardness is expressed non-dimensionally. Vickers hardness is defined by the impression force (F) and imprint surface.

Vickers hardness measurement can be used for any hardness. The method is very precise, and is minimally dependent on the load.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the