This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

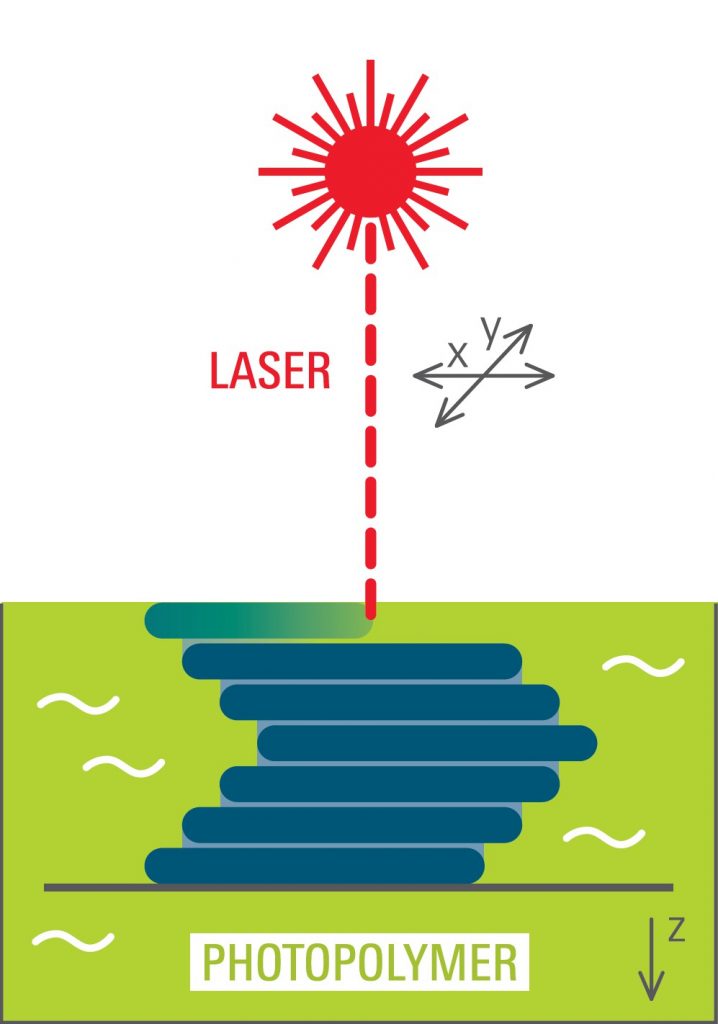

Stereolithography (SLA)

Stereolithography is a printing process where a product is created by hardening a resin using radiation. The most frequently used source of radiation is an UV laser beam. The areas hit by the beam, containing the light-sensitive resin, become solidified and create the printed layer. Then, the printed part is lifted to a height corresponding to the thickness of the original layer, making way for an unsolidified resin, which floods the area under the lifted part; the process is subsequently repeated until the entire object is complete.

This 3D printing method is becoming increasingly more popular. One of the reasons is its high precision prints with sharp details and smooth surfaces. The SLA method finds application in a number of disciplines such as product design, dental medicine, science and research, modelling etc.

This technology is becoming increasing accessible. The selection of SLA printers ranges from desktop to production and industrial 3D printers. Each type offers different functions, depending on a project’s complexity and size requirements of the final product. Also, the selection of light-sensitive thermosets has been increasingly wider. The offer also includes modelling resins with optional colour shades or transparency degrees; construction materials with enhanced mechanical properties; and, finally, medical materials with guaranteed biocompatibility. Another advantage is that the resins can typically be easily decolourized or further processed.

Schematic images of 3D printing technologies are used with the permission of Prof. Steffen Ritter.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the