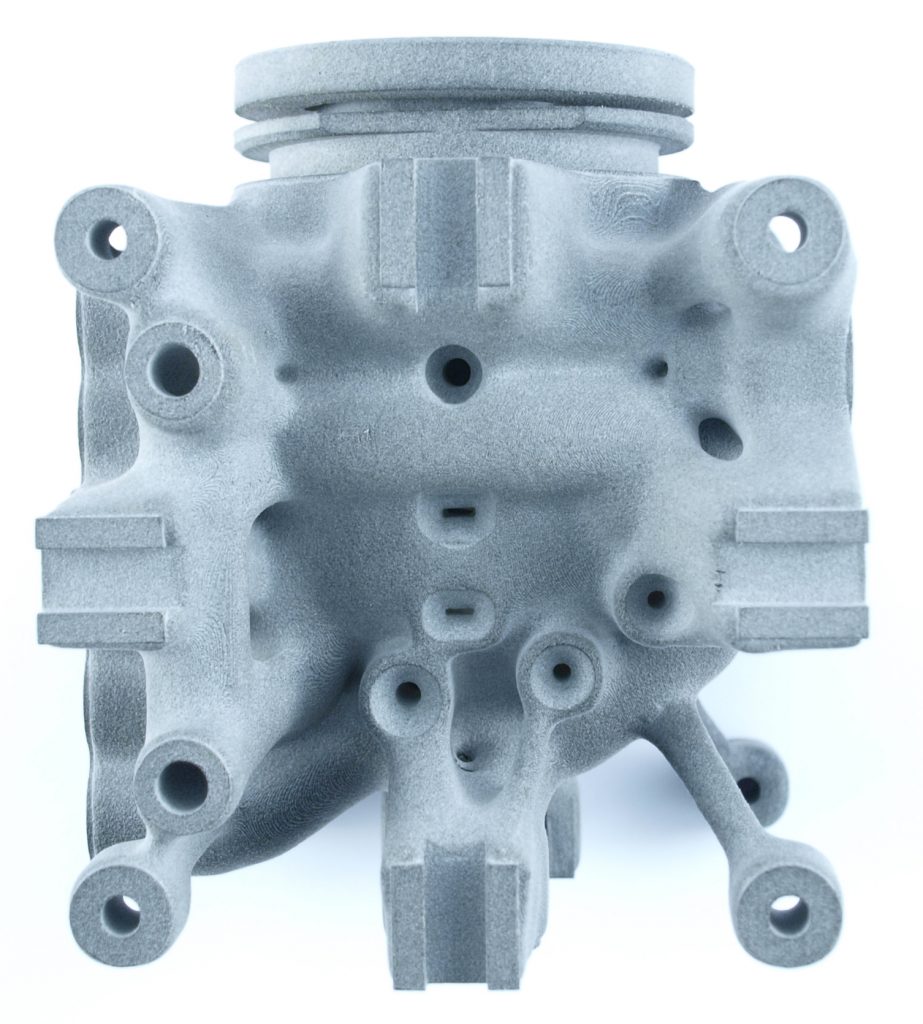

CARDAM and Beneš a Lát with the contribution of the Institute of Physics commissioned the first zinc-alloy injection mould produced using a unique procedure. This innovative approach has the following advantages:

- weight saving of 64 % in contrast to conventional production,

- approx. 30 % time saved on 3D printing due to topological optimization,

- production time shortened from a quarter of a year to approx. 1 month.

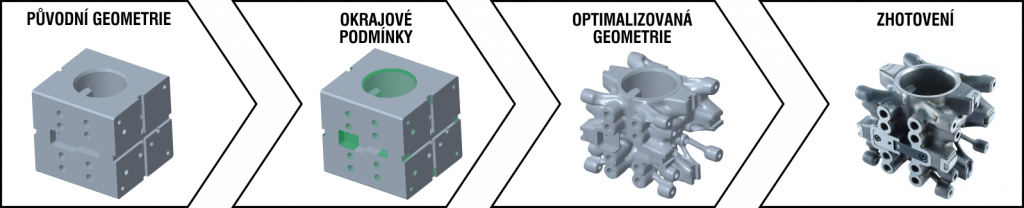

The topological optimization method, i.e. process during which unnecessary material is being gradually removed from a virtual model, was applied very early on at the design stage. This method decreases the product’s weight without compromising its functional properties, and, in the case of additive manufacturing also its price.

The production itself then didn’t follow the well-trodden path when the mould is produced using classic machining process, and the latest technologies were represented only by additive manufactured inserts fitted into the mould. A smart design enabled the creation of the entire mould using 3D printing.

More information is available, for example, in Hospodářské noviny.

Related services

Topological optimization

Topological optimization enables us to achieve a more efficient use of material under mechanical load and use it only where you really needed it.

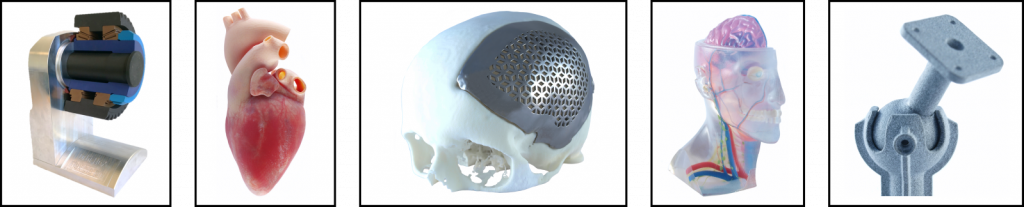

Custom 3D printing

Are conventional manufacturing processes holding you back from achieving shorter delivery times or complex geometries? Whether it is plastics, metals or composites, 3D printing is here for you.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the