This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

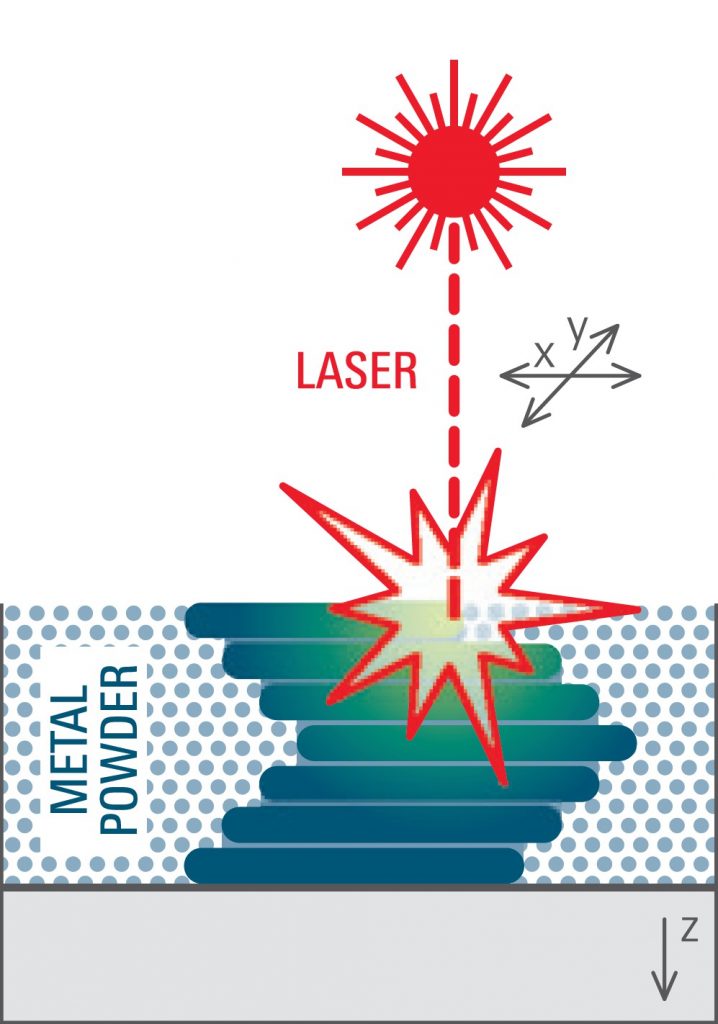

Selective laser melting (SLM)

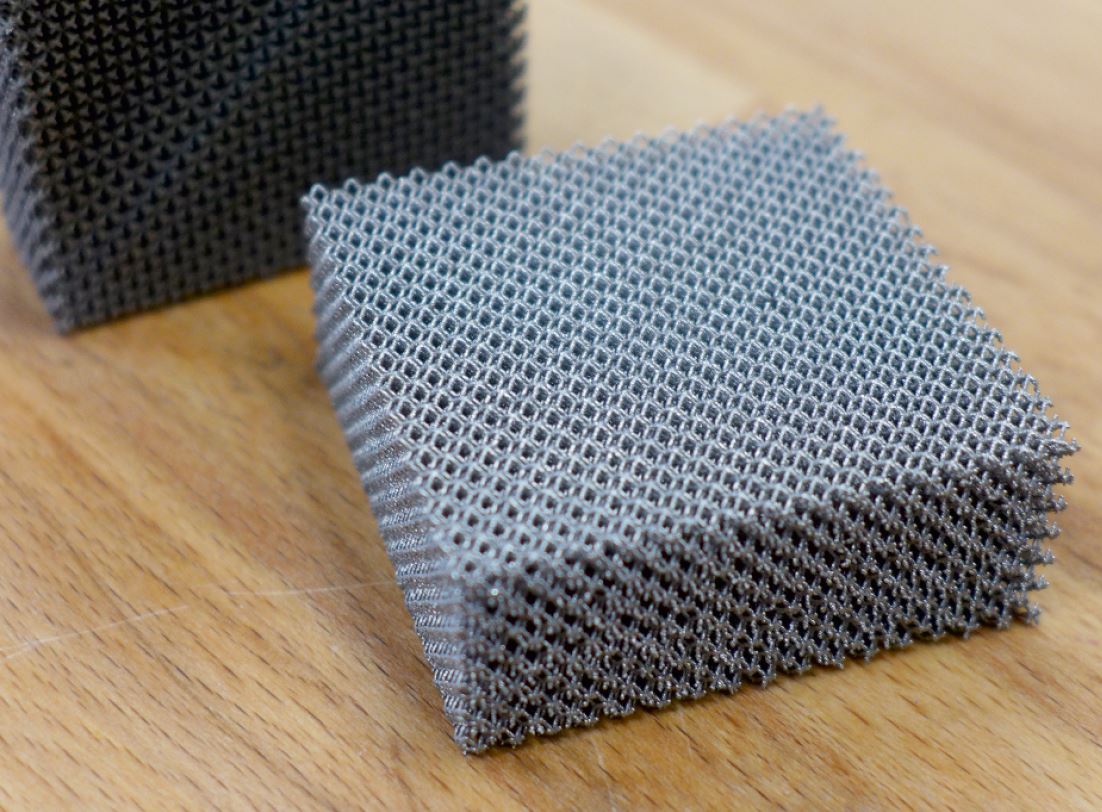

The technology stands out mainly as a method to create complex-shape metal parts that are difficult to process using conventional procedures. A metallic powder of a prescribed granularity is spread out on each layer of the model’s printing area and selectively melted using laser. This creates an interlayer bond between the current and the preceding layer; this process repeats itself up to the final shape. This great benefit of this technology is that it enables the creation of any complex structures.

One of the main assets of this printer is a small printing area which enables a relatively low-cost operation, and makes it easier to cover the whole printing platform with parts for printing. This leads to a higher material efficiency. The printer is equipped with one 200W laser device.

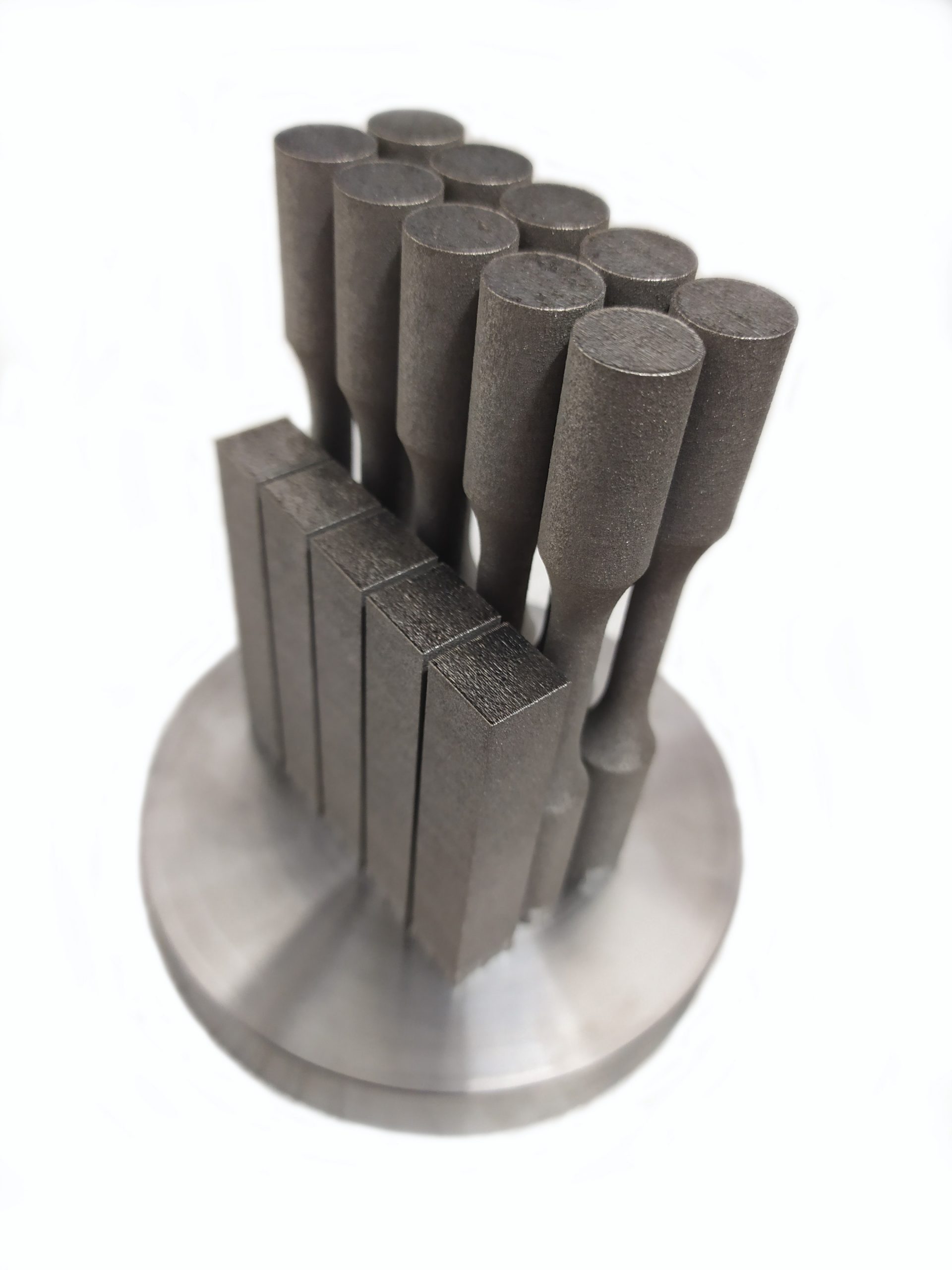

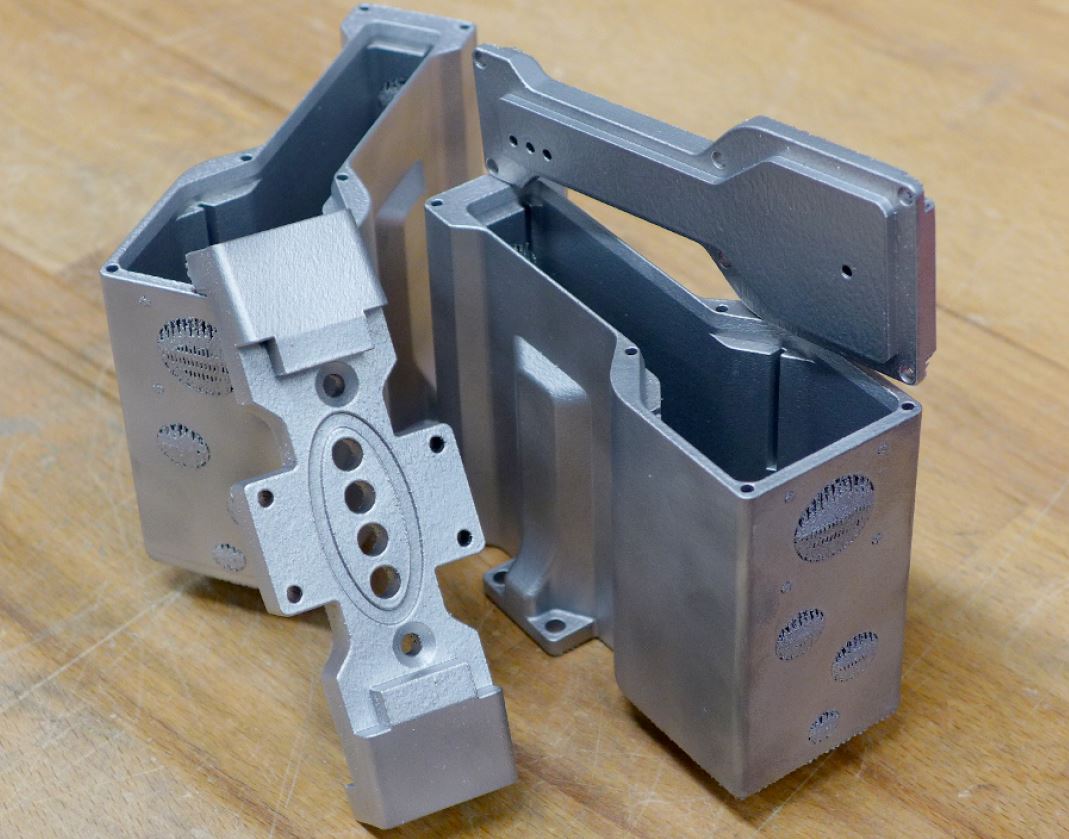

Product examples:

Technical parameters:

| Building space | 98 x 98 x 100 mm | |

| Layer thickness | optional in the range 10 µm – 50 µm | |

| Beam diameter | 55 µm | |

| Available materials | Stainless steel | SS630 |

| Tool steels | 1.2709 | |

| Aluminium alloys | AlSi10Mg | |

| Nickel-based alloys | In-718 | |

| Cobalt-Chrom | CoCr | |

| Copper-based alloys | CuNi2 | |

| Titanium-based alloys | Ti6Al4V ELI | |

SLM 280HL

This machine can produce metal parts with minimum porosity. It is equipped with one laser of the Yb:YAG with the maximum power of 400W.

Product examples:

Technical parameters:

| Bulding space | 280 x 280 x 365 mm | |

| Layer thickness | optional in the range 20 µm – 70 µm | |

| Beam diameter | 80 µm – 115 µm | |

| Available materials | Titanium alloys | Ti6AI4V, Ti6AI7Nb |

| Stainless steels | 1.4404 (316L), 1.4540 (15-5PH), | |

| Tool steels | 1.2344 (H13), 1.2709 | |

| Aluminium alloys | AISi12, AISi10Mg, AISi 7Mg, AISi9Cu32 | |

| Cobalt-Chrom | ||

| Nickel-based alloys | Inconel 718, Inconel 625, Inconel 939, Hastelloy X | |

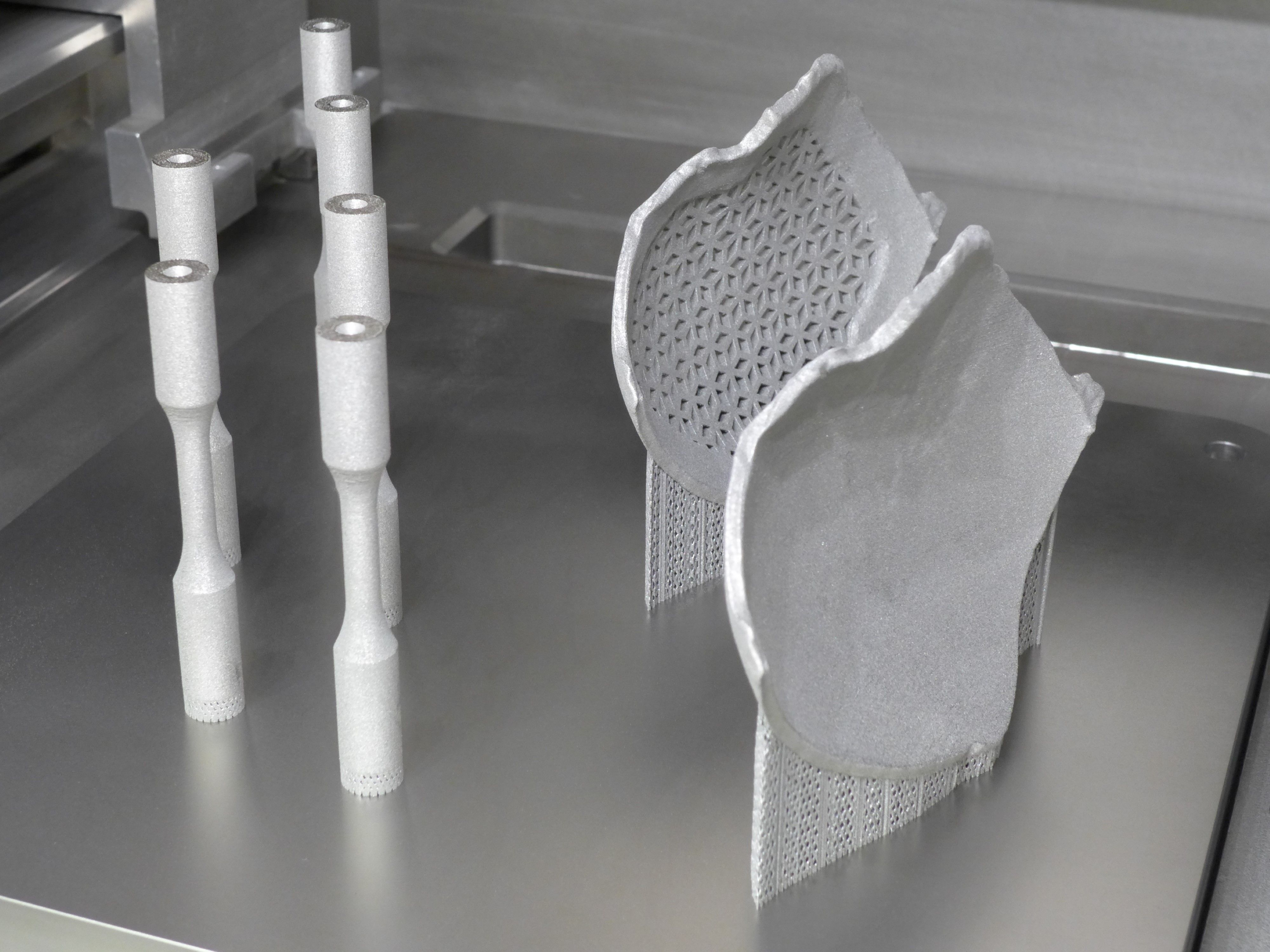

EOS M 290

EOS M 290 can work with metallic powders that range from aluminium alloys to steel and titanium alloys. The printing machine offers an industrial solution, incorporating a sifting station, which reduces waste materials and the costs of labour. The laser achieves a power of 400 W.

Technical parameters:

| Building space | 250 x 250 x 325 mm | |

| Layer thickness | optional in the range 20 µm – 60 µm | |

| Beam diameter | 100 µm | |

| Available materials | Titanium alloys | Ti6AI4V |

| Steels | 1.4404 (316L), MaragingSteel MS1 | |

| Aluminium alloys | EOS Aluminium AlSi10Mg | |

| Cobalt-Chrom alloys | MP1 | |

| Nickel-based alloys | Inconel 718, Inconel 625, EOS NickelAlloy HX | |

Schematic images of 3D printing technologies are used with the permission of Prof. Steffen Ritter.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the