This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

Hollow cathode

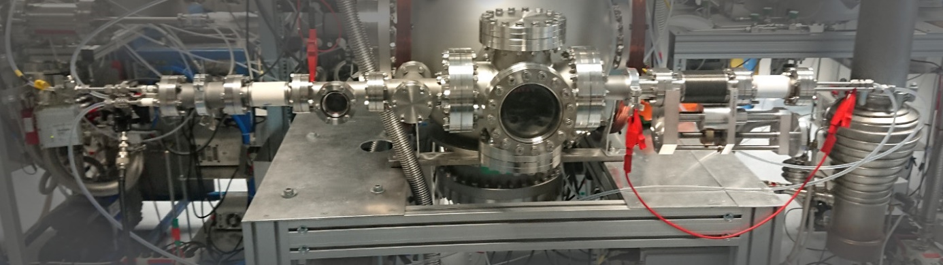

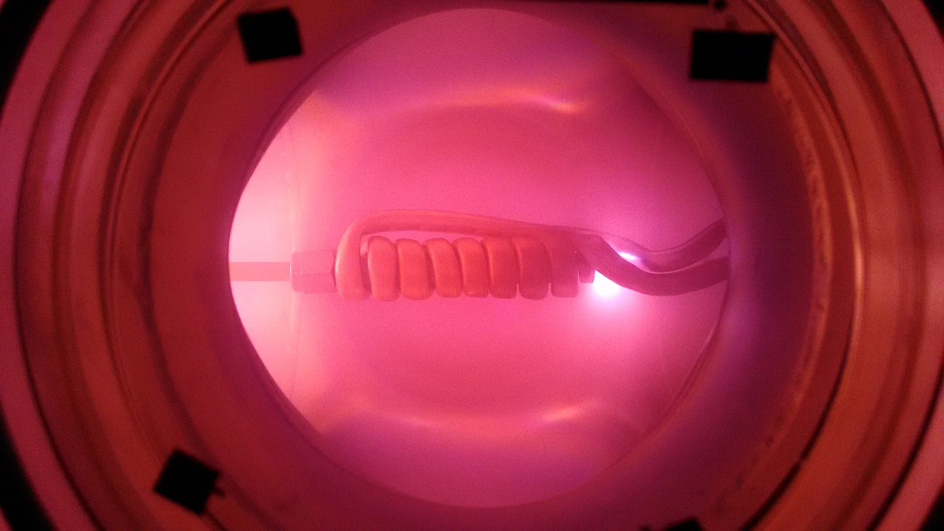

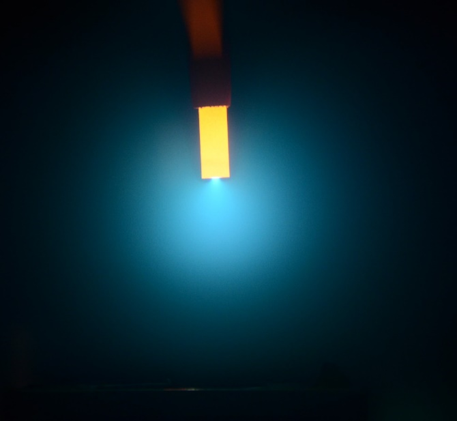

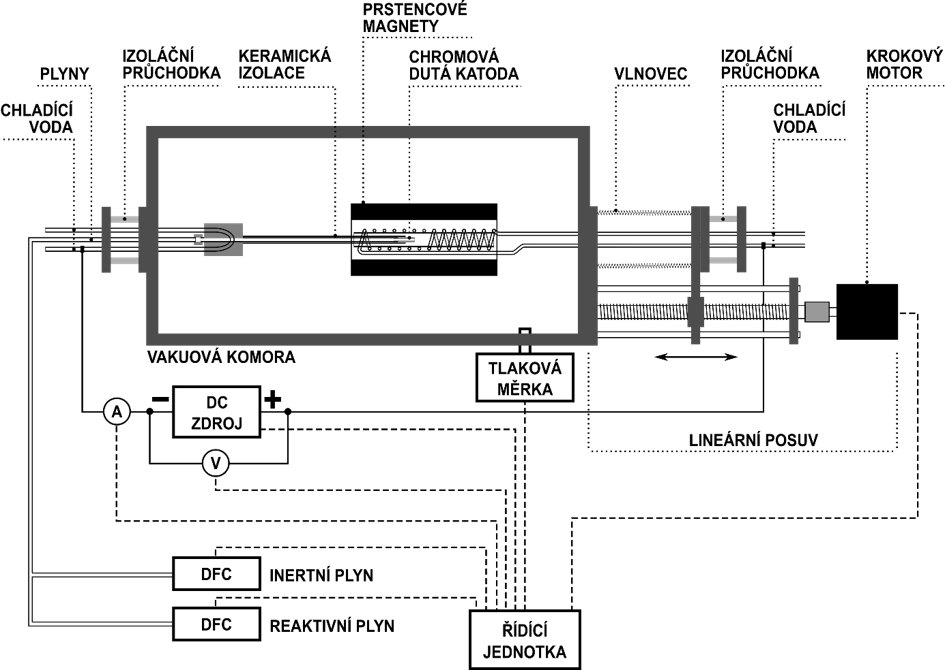

A hollow cathode deposition system is based on hollow cathode magnetron sputtering in the reactive atmosphere of the operation gas. The hollow cathode provides a high degree ionisation that causes not only an intensive cathode sputtering process but also the ionization of a reactive gas, and the subsequent improvement of the properties of the deposition layer induced by an increased bombardment of the substrate.

The active cathode is made of the sputtered material, and is placed at the end of an electrically insulated holder. The cathode is connected to a power supply, which ensures its sputtering. All deposition process takes place in a vacuum manipulation chamber which is a central part of the whole deposition system that offers the view of the deposition area and enables visual inspection.

This method uses the reactive sputtering effect. The reactive sputtering of solid, anti-abrasive layers is based on a precise dosing of a reactive admixture into operation gas. This precise dosing system is enabled by a feedback system that can suppress an undesired “cathode poisoning” effect and, at the same time, achieve the desired stoichiometry of the deposited layer.

The advantage of the hollow cathode is its ability to deposit material also into long pipes (holes) with a small internal diameter. The depositability of a substrate is always dependent on a part’s shape complexity and its size.

Hollow cathode enables the deposition of metallic layers (T, Cr, Al, Zr, V, W, Fe, Ni etc), hard, and anti-abrasive materials, and metal nitrides (CrN, TiN, ZrN etc.).

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the