This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

The NCC for MATCA has a rich variety of technology equipment that can be fully exploited and further advanced by its top experts. In addition to commercially available devices, it offers a unique, globally unprecedented infrastructure.

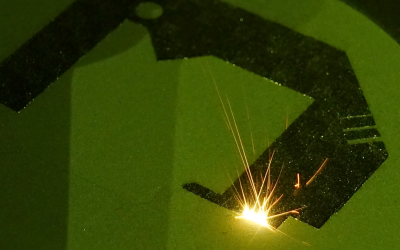

Additive manufacturing

3D printing or additive manufacturing allow the fast manufacturing of complex shape plastic, metal parts or parts from other materials.

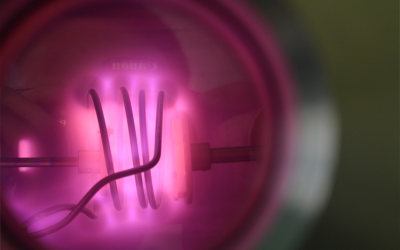

Plasma technologies

Plasma technologies offer a wide range of applications from coating using a wide selection of materials to waste processing and medical use.

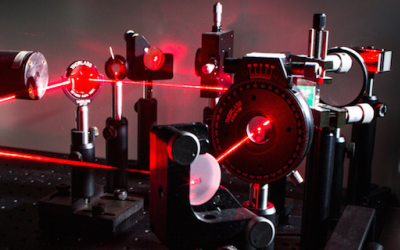

Laser technologies

In addition to characterisation or surface coating, laser technologies also enable the modification of surface functional properties without the application of any other material.

Analytical methods

Analytical methods enable the measurement of different chemical and physical quantities that have impact on material behaviour, production quality or product design.

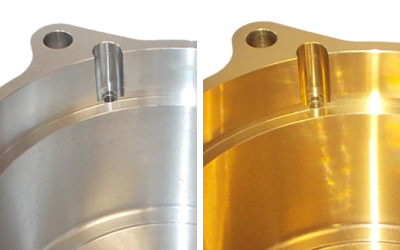

Surface treatment

Surface treatment methods significantly improve mechanical, anticorrosive, thermal and other useable properties of the product by modifying its surface or by applying a suitable coating to it.

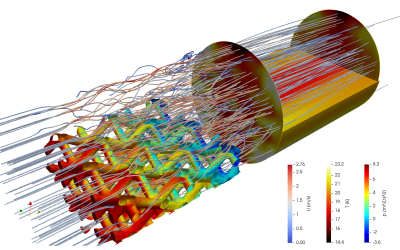

Numerical simulations

Numerical simulations enable the virtual testing of a future product; and the optimization of its properties or the elimination of its failures.

Supercomputers

Supercomputers made up of several computer clusters and disk servers can handle numerical calculations in a way that enables them to take part in national and international projects.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the