This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

WHY

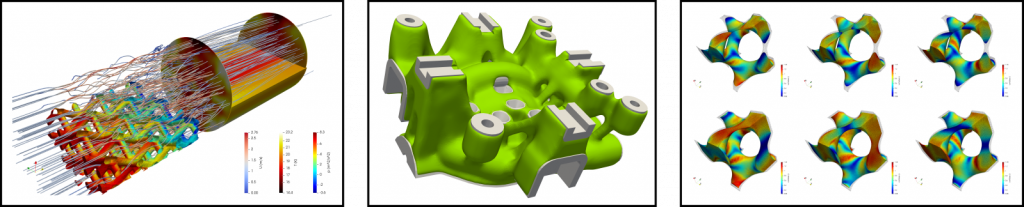

Every technologist dreams of reducing material waste. But it’s very difficult to tell exactly which parts of a design are superfluous and which ones are needed for the part’s optimal functioning.

HOW

Our extensive know-how of numerical simulations and the possibility of using computational clusters enable us to calculate optimization tasks even for the most intriguing designs.

WHAT

The knowledge of product application (functional surface, mechanical and other properties) and any technology requirements on its production allow us to optimize the shape of the final design. The use of materials is maximized, product weight is minimized.

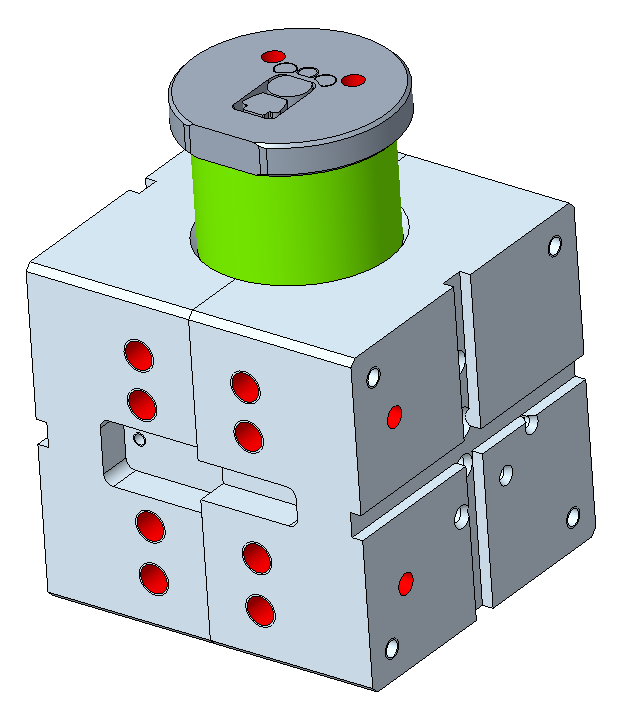

Example: Topology optimization for die casting moulds

Introduction

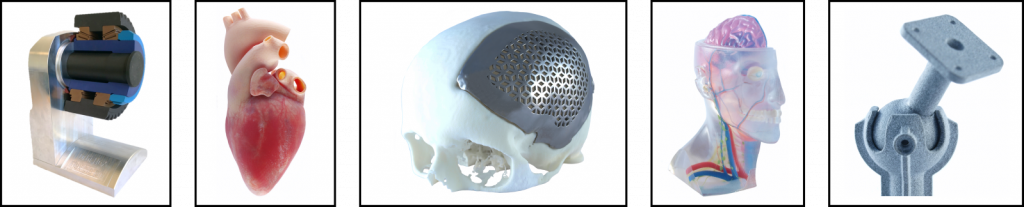

Our industrial partner specializing in pressure die casting of zinc-based alloys was looking to solve a cooling problem with their new casting mould. Due to a complex geometry of the cooling channels, they decided to go for 3D printing. Being aware of the benefits of the technology, they chose to reduce material costs by avoiding the printing of the entire material block. This is exactly the purpose of the topology optimization service – it decreases material waste while maintaining all important design parameters.

Solution of the problem

Given the demanding requirements on technology, the boundary conditions (constraints) for the use of the casting mould had to be clearly defined. These conditions included connecting points for cooling and casting media, construction space in the casting machine, fixation, acting forces, and properties of the casting material.

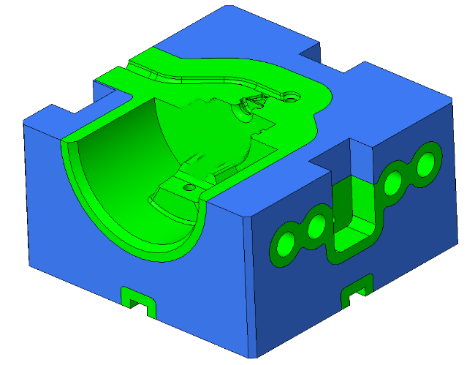

The key part of the design was to optimize the cooling element. Instead of the existing straight-drilled channels, the possibility of their replacement with round channels now arose. The combination of the additive manufacturing of the mould model and the casting of the final component required a close cooperation of additive manufacturing technologists and casting experts. Other issues to be solved included, for example, the distance of the cooling channels from the cast, channel geometry for media flow, and how to 3D print self-supporting channels.

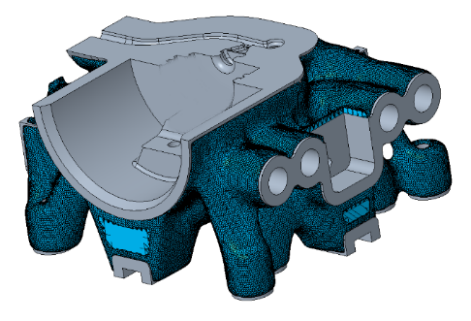

As for the technology to be used, priority was given to DMLS (Direct Metal Laser Sintering), the material was set to be tool steel 1.2709. For reasons of cost-effectiveness, 3D printing must consider the surface area of the cast relative to the printing platform (which is 250×250 mm in the case of EOS M290), and the total volume of the cast. Topological optimization applies all boundary conditions and forces, and iteratively eliminates any superfluous material. This helped save a lot of printing powder which the company can now use for other printing assignments.

In a specific design example, additive manufacturing was combined with conventional machining of a part of the mould. The resulting geometry was verified in a structural analysis, using the method of final elements. The design’s merit for die casting was also evaluated by the casting simulations software called MAGMA. The model was then complemented with machining add-ons and with any structures needed to ensure that the additive manufacturing process is in compliance with all technological principles.

Merits

The printing of a half of the mould took approximately 21 hours. Topology optimization helped reduce the printing time by 30 % and material waste by 64 %. The project fully benefited from conformal cooling and the production price compared well with a conventionally produced mould. Practical casting tests demonstrated that the bearing capacity of the casting is by 30 % higher, which is a result of improving the quality of technological principles of high-pressure casting, primarily by decreasing the number of casting defects. This also led to reducing the wasteage rate in parts manufacture. You can read more about the project here.

Do you have any questions?

The range of analytical methods available in the NCC for MATCA is too extensive to be fully outlined here. If you have any questions concerning a specific application, don’t hesitate to contact us.

Related technologies

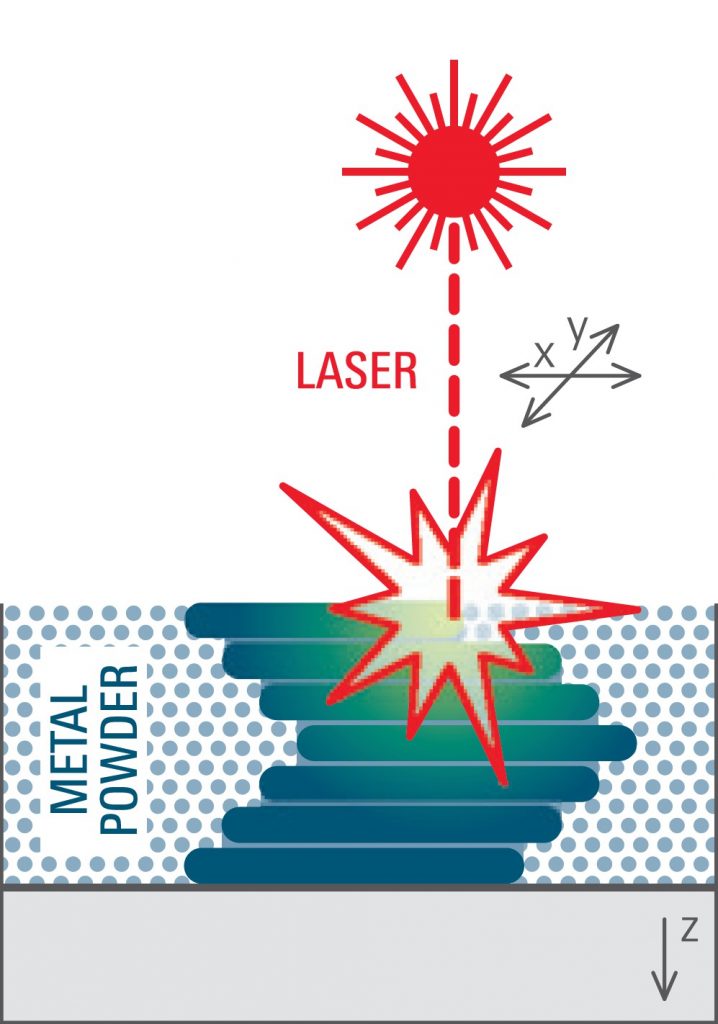

Selective Laser Melting (SLM)

Selective laser melting is a production method which is similar to SLS and focuses on the processing of powdered metallic materials. The method uses the laser to directly melt the metallic powder located in areas that are defined by the shape of manufactured part’s layer. As soon as one layer is complete, the printing platform lowers by one printing layer, and another layer is applied, and the entire process repeats itself till the whole part is complete. More >>

Machines in the consortium: TruPrint 1000, SLM 280HL, EOS M290

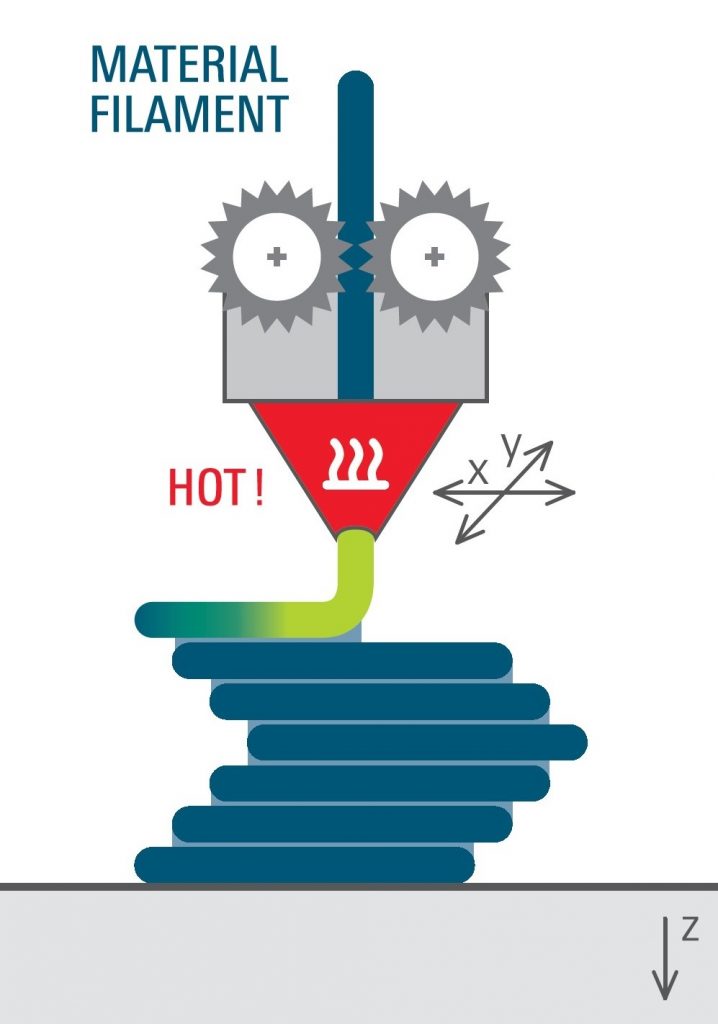

Fused Deposition Modelling (FDM)

The printing process is based on the deposition of individual layers of molten thermoplastic that are supplied to the print head in the form a filament or granulate. After its application, the molten material cools down and solidifies. The resulting quality of the product relies on printer design quality and on how well the printing parameters are tuned to the thermoplastic and the printing machine used. More >>

Machines in the consortium:

Stratasys Fortus 450mc

Prusa i3 MK3s

Related services

Custom 3D printing

Are conventional manufacturing processes holding you back from achieving shorter delivery times or complex geometries? Whether it is plastics, metals or composites, 3D printing is here for you.

Virtual modelling

Numerical simulations allow us to make virtual models of parts, assemblies and production processes. They enable the optimization of usable properties or the prevention of failures in operation.

Schematic images of 3D printing technologies are used with the permission of Prof. Steffen Ritter.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the