This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

Hybrid water-stabilized plasma spraying

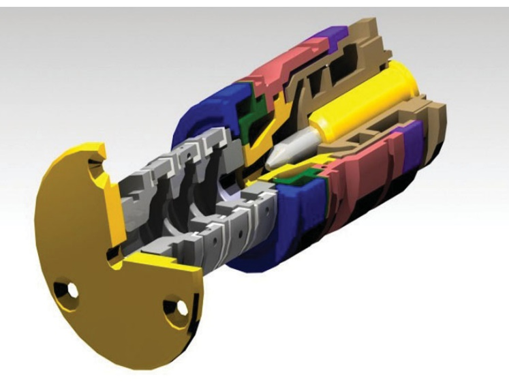

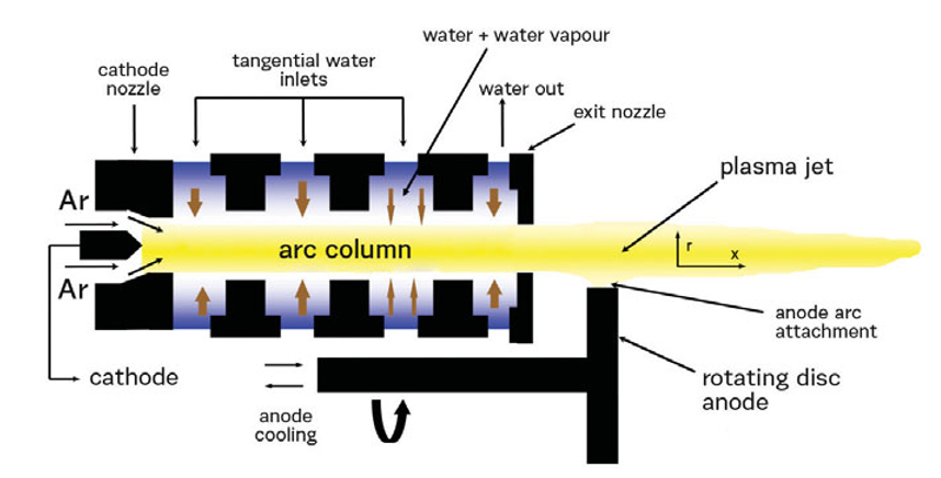

Hybrid water stabilized plasma spraying (WSP-H) is a novel hybrid technology using a plasma torch that combines the benefits of a classic gas stabilized DC arc torch with a uniquely designed water duct. The water duct supplies the plasma arc with hydrogen and oxygen. The WSP-H system may continually work at a power of 180 kW with the consumption of 15 slm argon and 20 ml/min demineralised water.

Its construction is based on water stabilized plasma torch (WSP), which has been used in industry for over 30 years. The hybrid WSP torch has advantages for everyday operation. This concept is based on argon and a tungsten cathode located at the back of the water ducts, which simplifies the use of the torch, providing higher reliability and longer operation times while maintaining a highly enthalpic plasma.

A unique WSP-H 500 machine is the most cost-effective plasma deposition system, enabling the combination of low-cost operation (15 slm of argon and 20 ml/min of demineralized water) and a higher material deposition rate of up to 40 kg/h. The cost-effectiveness of this technology can’t be compared to any other gas stabilized plasma torches.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the