This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

Impact strength test

In everyday operation, a mechanical part is often exposed to cyclically changing forces. The impact-based forces are very dangerous, because they can initiate the destruction of material with a force, which wouldn’t damage the material under static load. In order to determine the behaviour of a material, which is exposed to abrupt changes of load, impact strength testing is used.

The principle of pendulum impact hammer for breaking a specimen apart and the subsequent deduction of the used energy dates back to 1901. In that year, Frenchman G.Charpy lectured on how to determine impact strength by breaking notched prismatic rods at the meeting of the International Union for Technical Testing of Materials in Budapest.

Eight years later at the Congress in Copenhagen, the Charpy’s test was recommended for standardisation, which made it a widely-used method across Europe.

Charpy impact bending test

As said above, Charpy test aims to determine the value of impact work that is necessary to break the testing sample apart. The test must be performed under predetermined conditions, including specimen temperature, loading method (symmetrical three-point load bending), loading speed and specimen shape and geometry, including notch shape and size. The exact test specification is indicated in ČSN EN 10 045-1.

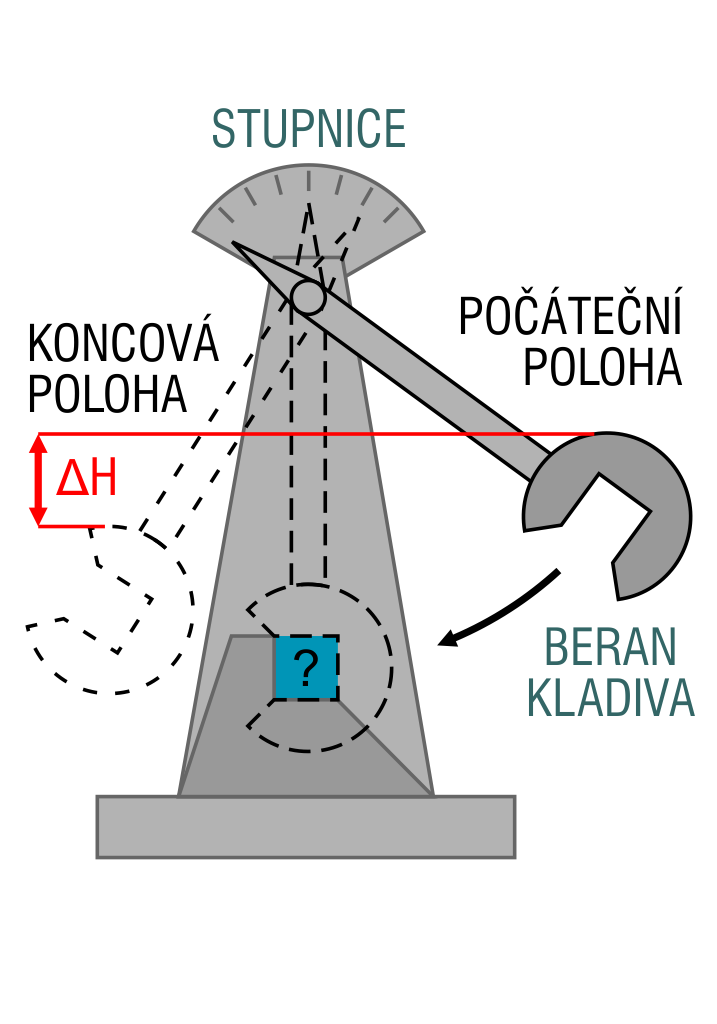

The test is performed in the following way. First, the hammer is fixed in an initial position, whose potential energy will be equal to the kinetic energy when the hammer is breaking the specimen apart. The sample is then placed between stops, with the back-side in the direction of the hammer’s motion, and as precisely as possible in the axis of the hammer. At this stage, it is necessary to reset the indicator of the impact work to zero, or put on other sensors, if any. The hammer is then released from its initial position to break the sample. The hammer is stopped mostly using a manual break.

From a theoretical point of view, we can determine the energy used by calculating the difference between the potential energy of the hammer in its initial position and after breaking the sample when it reaches a specific height that is equal to the potential energy at the start, reduced by the energy used to break the sample. This after-break energy is usually read on the hand clock.

Another value that can be obtained from the data acquired in this way is impact strength. This material characteristic is defined as a quotient of the impact work and the cross-sectional area at the notch. This value is specified as KCV, KCU2 or KCU3, with the third letter showing the type of notch, the numeral shows notch depth.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the