This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

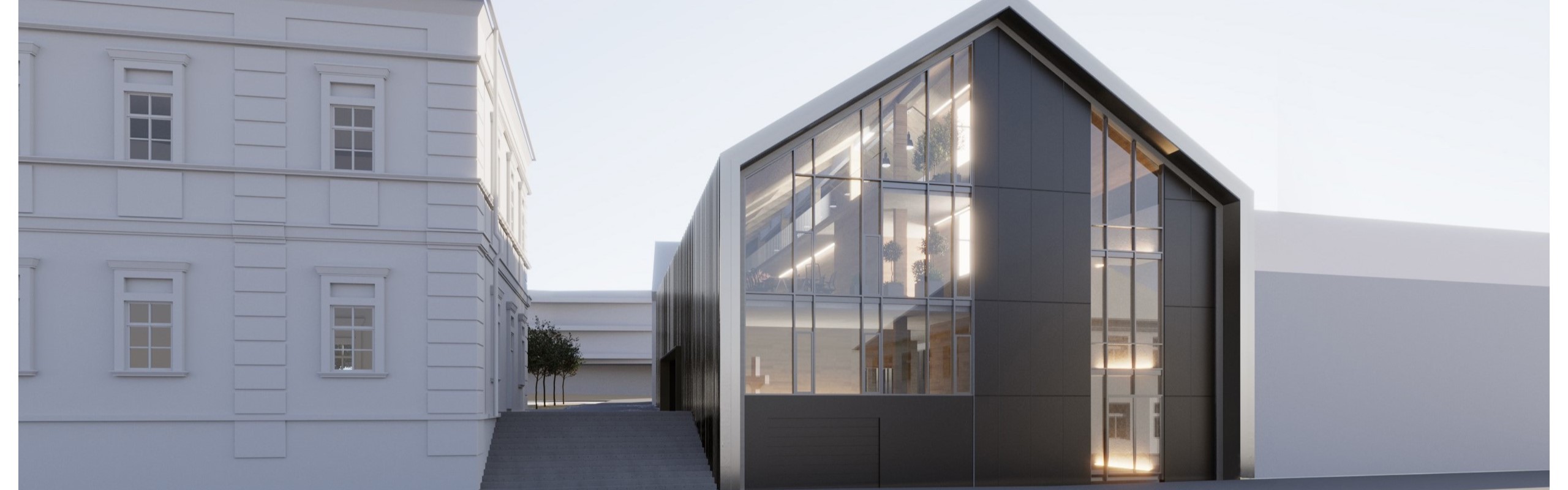

The mission of the National Centre of Competence (NCC) for MATCA is to provide leading-edge technology solutions regardless of the complexity of an assignment – from sudden production problems to long-standing societal challenges. For this purpose, the consortium brings together top experts from industry and academia that make use of their broad experimental and production backgrounds to provide unconventional and innovative solutions. Their solutions are implemented as joint projects or joint services.

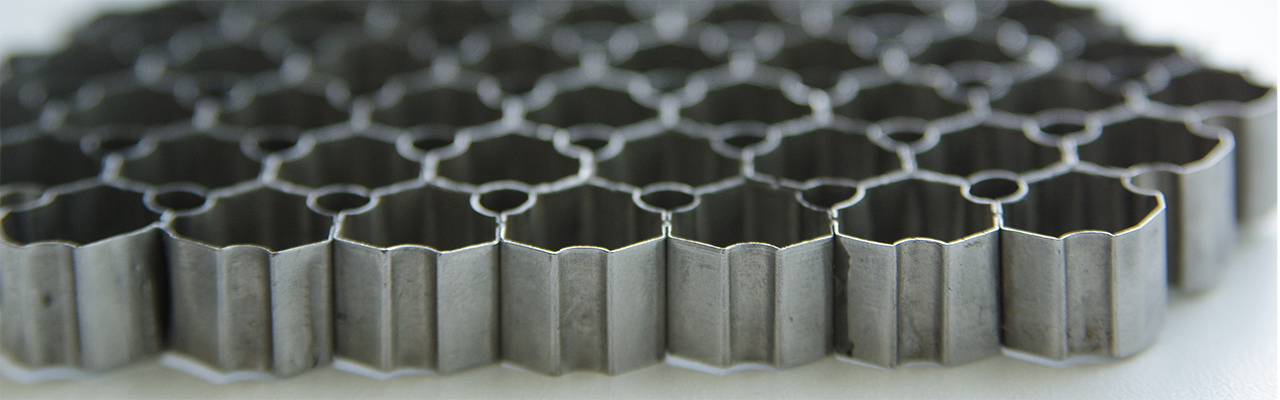

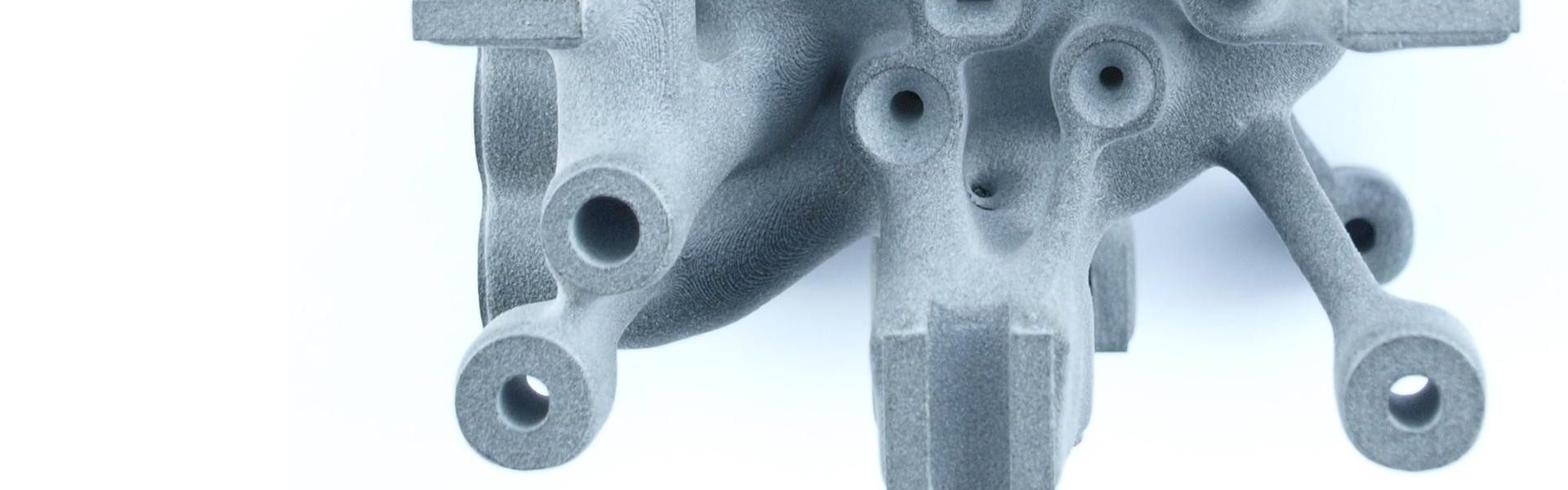

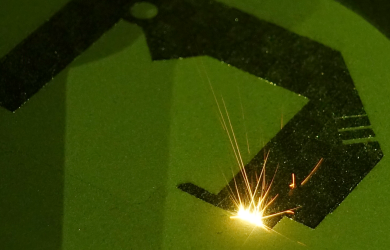

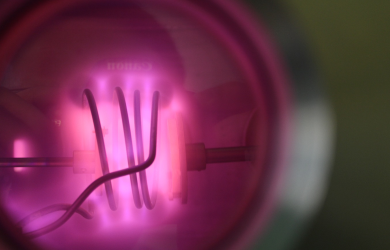

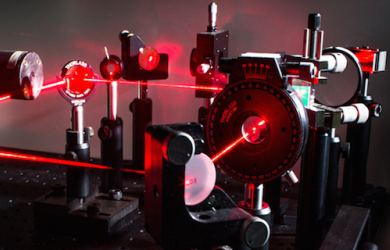

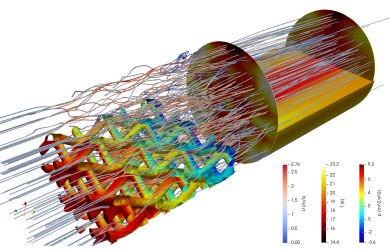

The Centre primarily develops additive, plasma and laser technologies that have a major impact on industry, economy and security, therefore mastering and developing the technologies are matters of strategic importance.

As part of its long-term R&D projects, the NCC for MATCA covers the whole product life cycle – from smart design and green production, to the repairs and restoration of functional properties and hazardous waste disposal.

Along with research, development and service provision, the NCC for MATCA is involved in raising awareness and providing training to students and the general public.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the