This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

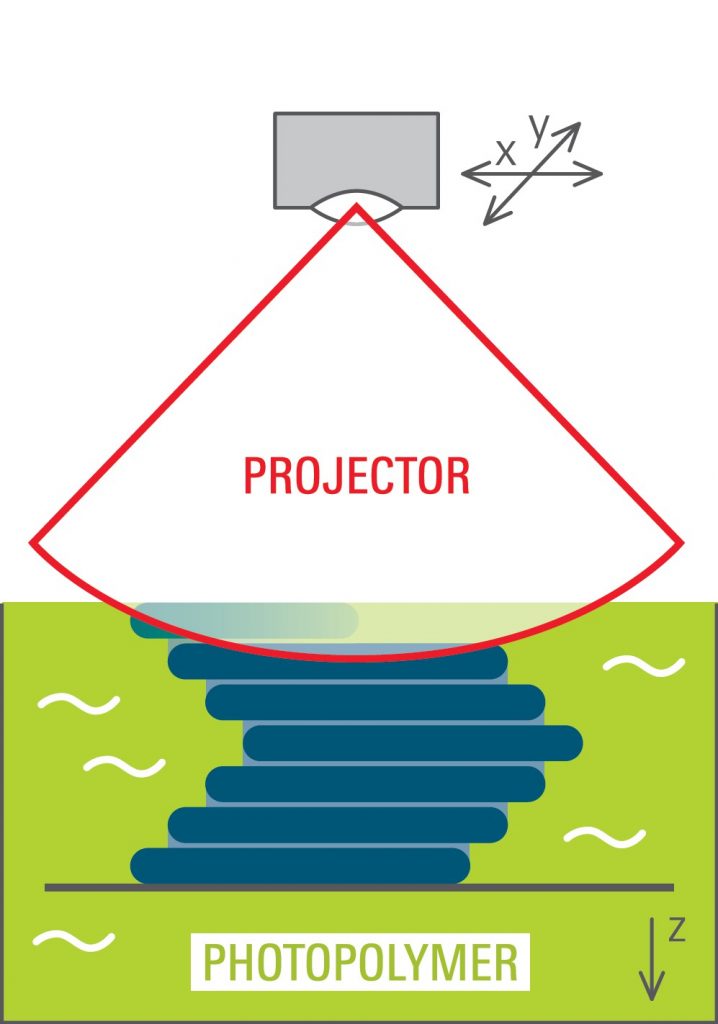

Direct Light Processing (DLP)

The technology uses selective hardening of a part of a photopolymer bath, using a UV radiation source located below an LCD display which shields the exposed layer to create a desired shape. The hardening process goes layer-by-layer. This printing method is used for very detailed designs, with a very high surface quality and dimensional precision which is higher than that of FDM technologies.

Průša SL1

A DLP based printer can print products with high-quality surface, high level of detail and minimum manufacturing waste. As one of a few printers, it can print from transparent (but matte) materials.

Product examples:

Technical parameters

| Building space | 150 × 68 × 120 mm | |

| Layer thickness | 0,025 – 0,1 mm | |

| Available materials | hard resins | different colours |

| casting resin | different colours | |

| flexible resin | different colours |

Schematic images of 3D printing technologies are used with the permission of Prof. Steffen Ritter.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the