This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

WHY

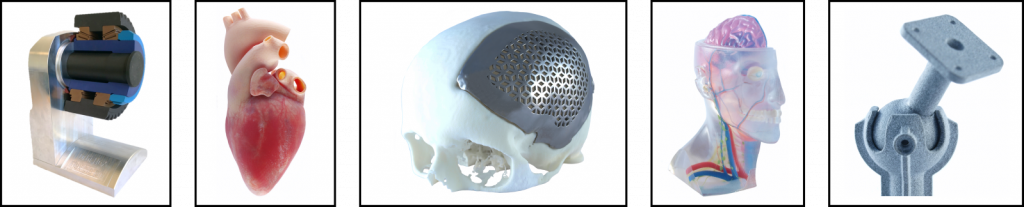

No new product should skip the prototyping stage before its market roll-out. This stage produces many preliminary products which require a similar geometry and, frequently, also similar mechanical and chemical properties like those of the final product. This part is typically very lengthy, involving repeated processes, even if the added-value is only apparent in the final prototype. But this can change!

HOW

Creating new product prototypes brings together experienced designers and 3D printing specialists. They cooperate on the preparation of calculations and materials, saving priceless time that would otherwise be spent on conventional prototyping.

WHAT

Each prototype is produced and subsequently tested in close cooperation and consultation with the customer, which ensures time and technology optimizations of the final product.

Example: Casting mould of rocker arm model

Introduction

One of our industrial partners was looking to optimize the centre of gravity for one of its parts. His was asking for injection technology and a predetermined distribution of mass around the central axis.

Solution of the problem

The mould geometry was designed based on the technology intended for the production of the part in bigger batches. The prototype of the new mould was 3D-printed within several hours. After testing repeatability, and following further optimization and another mould print, the mould was ready for serial production.

Merits

The 3D-printed mould considerably reduced the time delay between the mould design and its serial production. This relieved the supply chain and increased our industrial partner’s competitiveness in terms of timely delivery of new parts.

Do you have any questions?

The range of analytical methods available in the NCC for MATCA is too extensive to be fully outlined here. If you have any questions concerning a specific application, don’t hesitate to contact us.

Related technologies

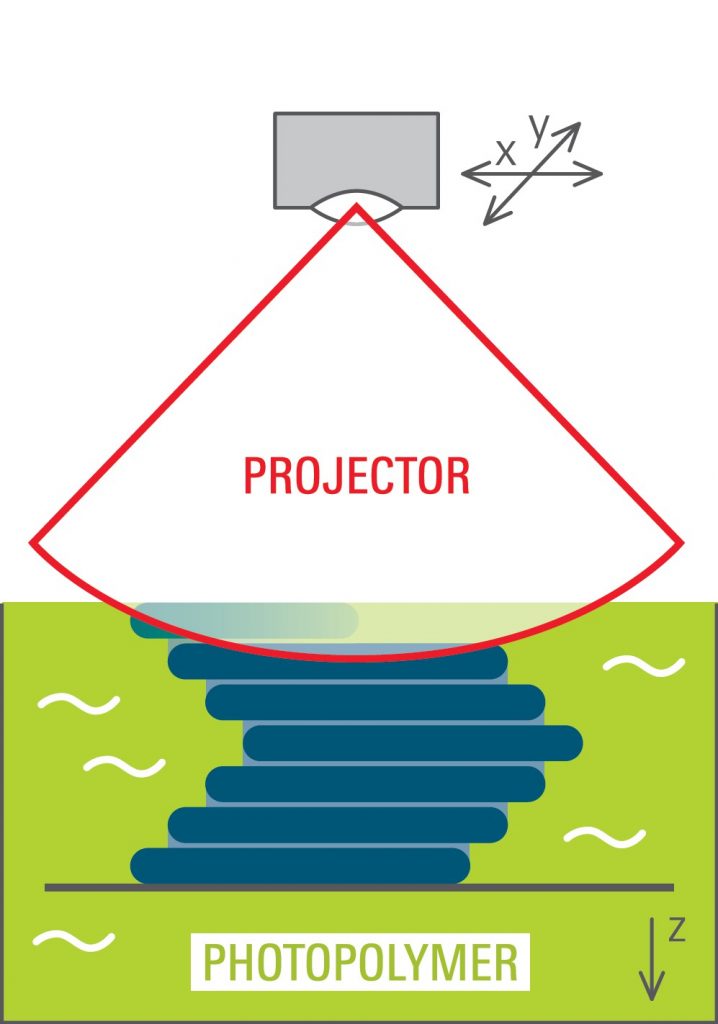

Direct Light Processing (DLP)

The technology uses selective hardening of a part of a photopolymer bath, using a UV radiation source located below an LCD display which shields the exposed layer to create a desired shape. The hardening process goes layer-by-layer. This printing method is used for very detailed designs, with a very high surface quality and dimensional precision which is higher than that of FDM technologies. More >>

Machines in the consortium:

Prusa SL1

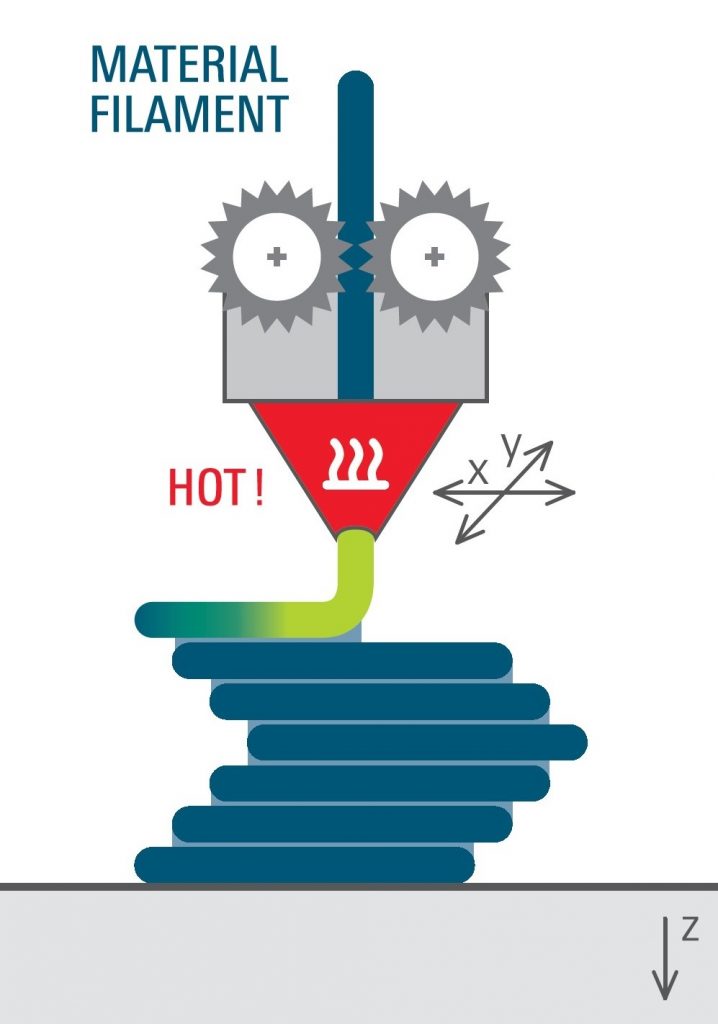

Fused Deposition Modelling (FDM)

The printing process is based on the deposition of individual layers of molten thermoplastic that are supplied to the print head in the form a filament or granulate. After its application, the molten material cools down and solidifies. The resulting quality of the product relies on printer design quality and on how well the printing parameters are tuned to the thermoplastic and the printing machine used. More >>

Machines in the consortium:

Stratasys Fortus 450mc

Prusa i3 MK3s

Related services

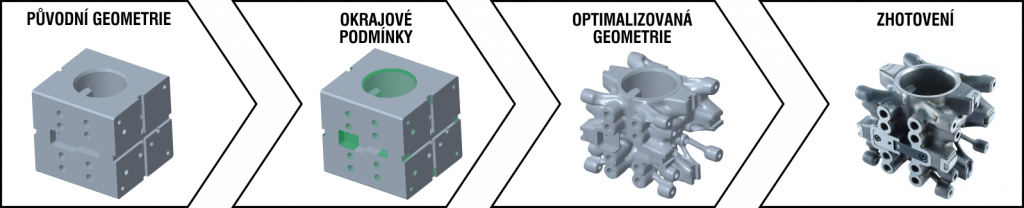

Topological optimization

Topological optimization enables us to achieve a more efficient use of material under mechanical load and use it only where you really needed it.

Custom 3D printing

Are conventional manufacturing processes holding you back from achieving shorter delivery times or complex geometries? Whether it is plastics, metals or composites, 3D printing is here for you.

Schematic images of 3D printing technologies are used with the permission of Prof. Steffen Ritter.

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the