This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Vyhledávání

Laser technologies

In addition to characterisation or surface coating, laser technologies also enable the modification of surface functional properties without the application of any other material.

Surface treatment

Laser Shock Peening

Laser Shock Peening (LSP) is a process that uses nanosecond high-energy laser pulses to create compressive residual stresses in the material, with nominal depths of up to 1.5 mm. More >>

This technology is available in the consortium.

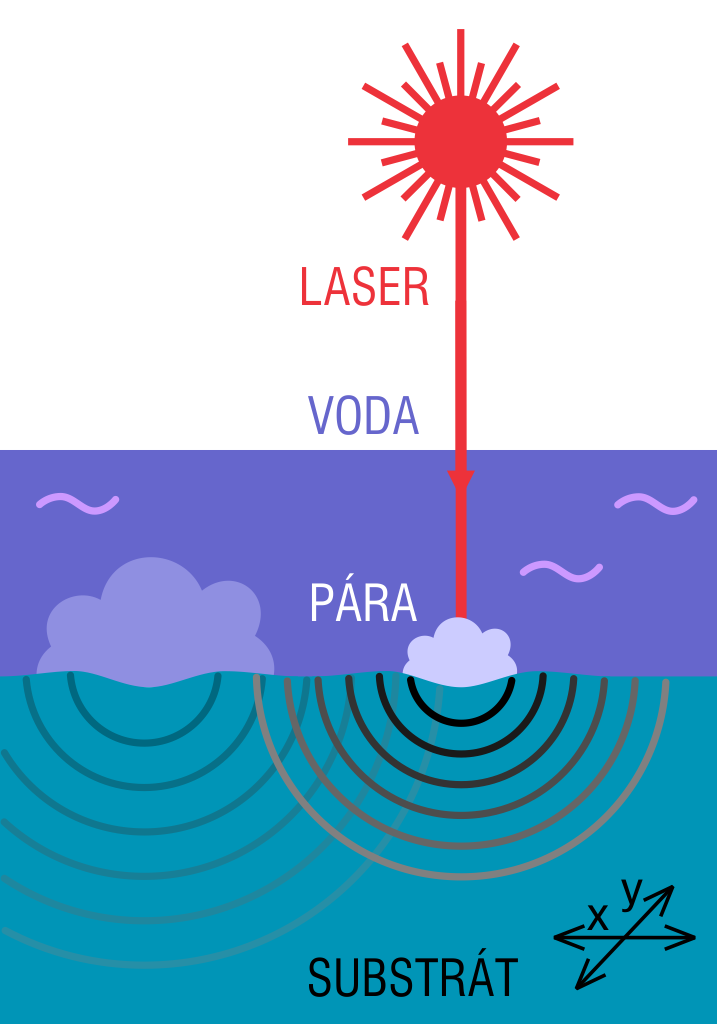

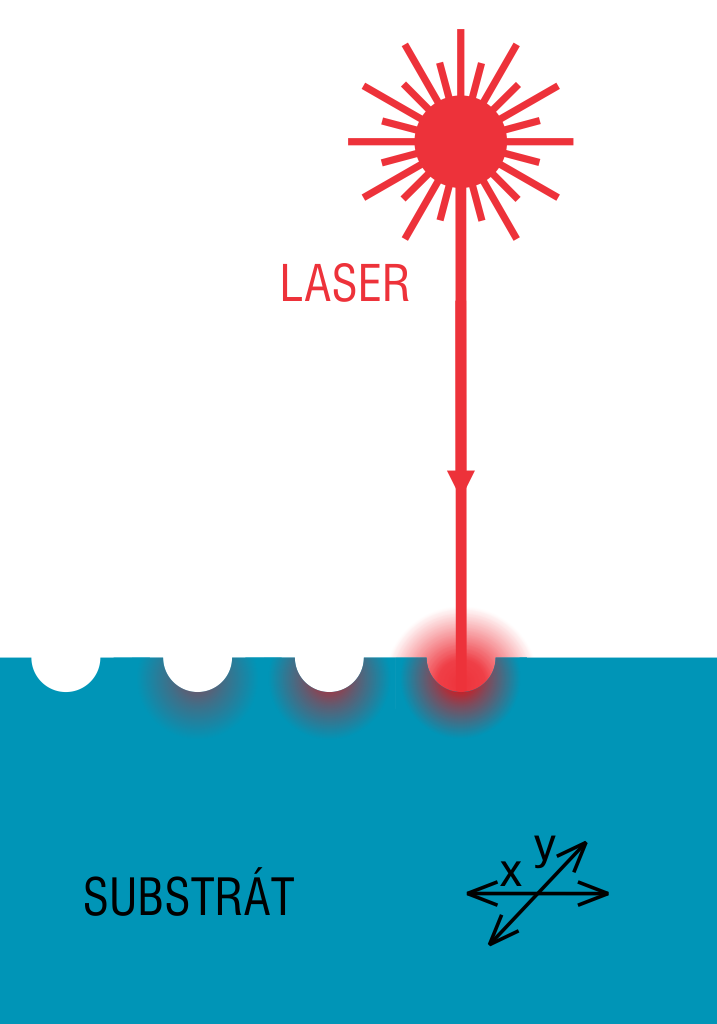

Micromachining

Laser micromachining technology uses a laser beam that is focused on a small area of the machined material, making it heat up to a high temperature at which the material starts to evaporate. More >>

This technology is available in the consortium.

Laser-assisted coating

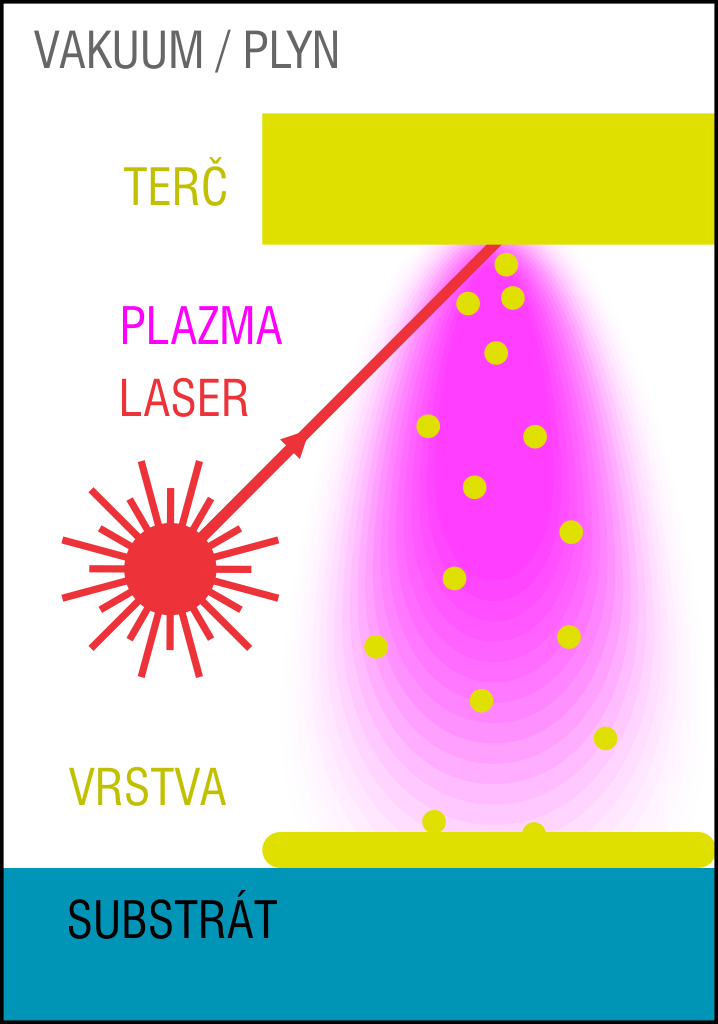

Pulse laser deposition

Pulse laser deposition (PLD) is a method for creating inorganic and – to a limited extent and subject to some modifications – organic thin layers from materials with a complex elemental composition. In its original form, this method was first published in 1965. More >>

Available in the NCC for MATCA:

more than 5 devices

The NCK for MATCA is supported by the

The NCK for MATCA is supported by the